Indoor testing method for drawing strength of waterproof bonding layer paved on steel bridge deck

A waterproof adhesive layer and pull-out strength technology, which is applied in the field of steel bridge deck pavement, can solve the problems of failure load, waterproof adhesive layer disturbance, and large test variability, so as to achieve the effect of reducing variability and damage

Pending Publication Date: 2021-02-12

SOUTHEAST UNIV

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this method of testing has many disadvantages

First of all, the core drilling process will inevitably cause disturbance to the waterproof bonding layer, which cannot truly reflect its bonding performance

Secondly, it is difficult for this type of test method to ensure that the pulling speed is consistent, resulting in a large variability in the test

In addition, this type of test method can only measure the peak failure load, and lacks dynamic tracking of the loading process

Therefore, at this stage, the pull-out test for the waterproof bonding layer of the steel bridge deck pavement has defects such as low precision, large variability, and difficulty in reflecting the dynamic process of the test. Therefore, a new pull-out strength test method is needed to evaluate steel bridges. Adhesive Performance of Surface Pavement Waterproof Adhesive Coating

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

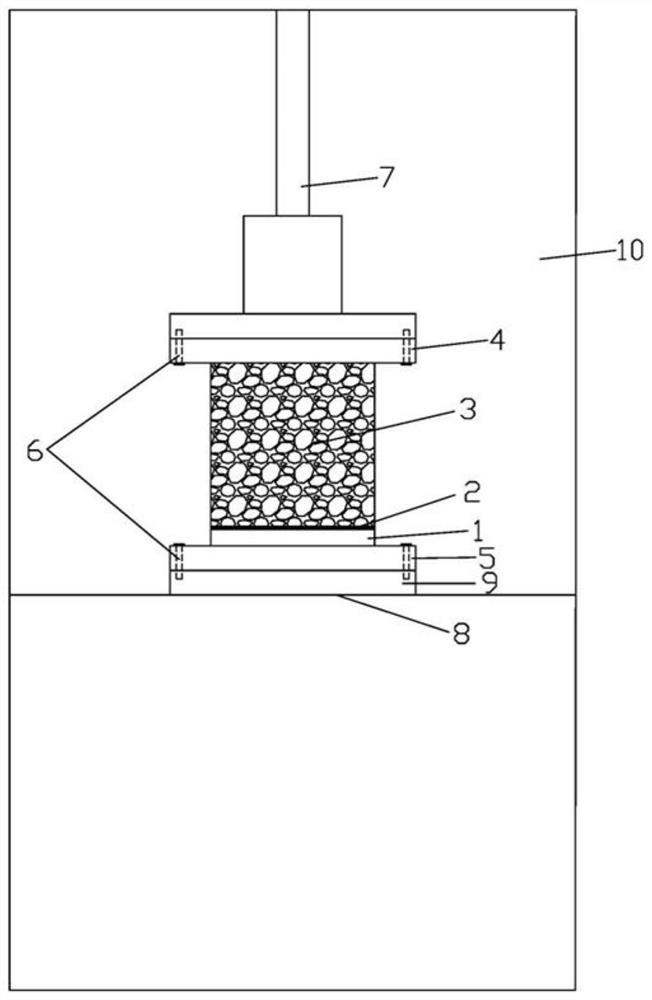

[0022] Aiming at the "steel plate-waterproof adhesive layer-modified asphalt SMA" bridge deck pavement structure, the invention is used to test the pull-out strength of the waterproof adhesive layer at 25°C.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

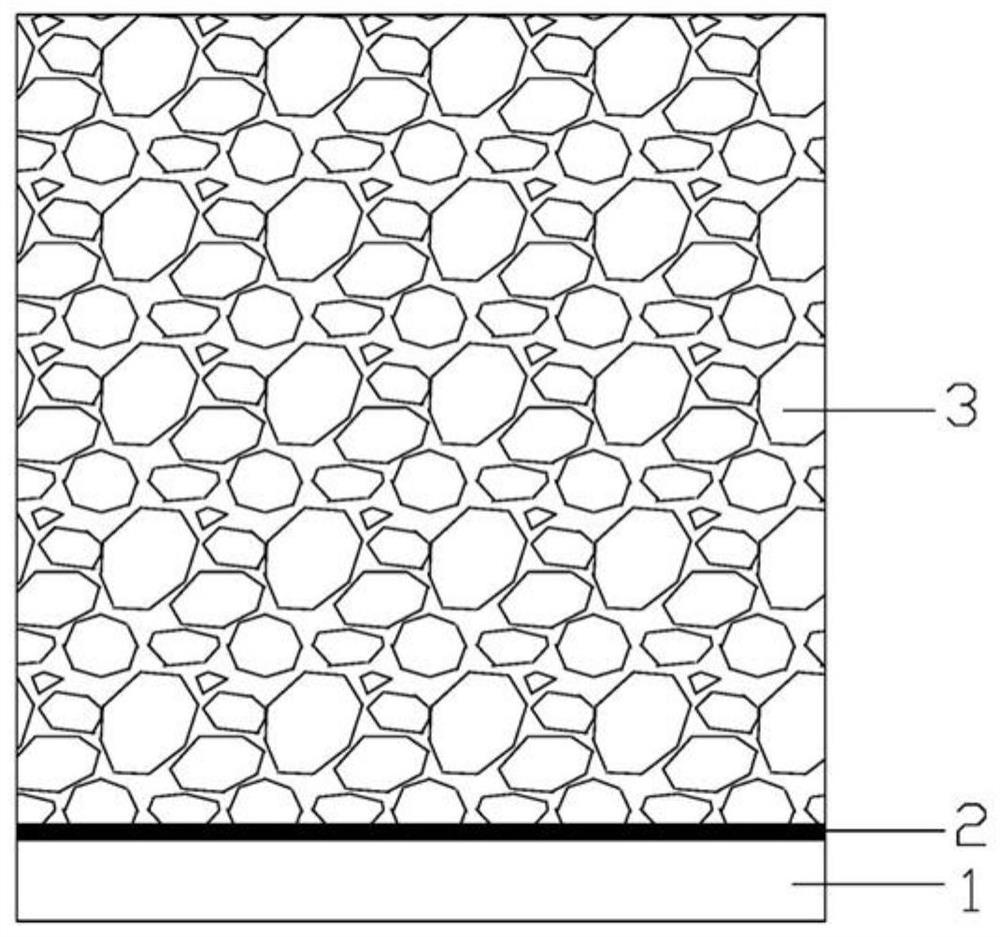

The invention discloses an indoor testing method for the drawing strength of a waterproof bonding layer paved on a steel bridge deck. According to the method, the steel blocks are polished and derusted indoors, the zinc-rich paint and the waterproof bonding layer are painted indoors, and the composite test piece with the steel blocks is formed under the high-temperature condition by using a rotarycompactor, so that the field construction process of steel bridge deck pavement can be well simulated. According to the indoor drawing test method based on a universal testing machine, the test temperature and the drawing rate can be accurately controlled, a force-displacement curve in the drawing test process can be directly obtained, the test method is simple and convenient, and the bonding performance of the waterproof bonding layer paved on the steel bridge deck can be truly reflected.

Description

technical field [0001] The invention belongs to the technical field of steel bridge deck pavement, in particular to an indoor testing method for the pull-out strength of a waterproof bonding layer of steel bridge deck pavement. Background technique [0002] The waterproof adhesive layer is an important part of the steel bridge deck pavement system. The failure of the waterproof adhesive layer will not only cause delamination, shifting, bulging and other diseases of the pavement layer, but also cause rainwater to seep into the steel plate, causing the steel plate to crack. Rust prematurely, thereby reducing its service life. It can be seen that the quality of the waterproof bonding layer directly affects the service life of the bridge deck pavement and the safety of the bridge structure. Adhesive performance is one of the key indicators reflecting the performance of the waterproof adhesive layer, and the adhesive performance is mainly evaluated by the pull-out test. [0003...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N19/04G01N1/36

CPCG01N19/04G01N1/36G01N2001/366

Inventor 倪富健丁子豪丁济同韩亚进赵子力

Owner SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com