Wear prevention device for wear prevention of circulating fluidized bed water cooling wall and installation method of wear prevention device

A circulating fluidized bed and water-cooled wall technology, which is applied to fluidized bed combustion equipment, combustion methods, and fuels burned in a molten state, can solve the problems of poor anti-wear effect and high cost, and achieve high manufacturing efficiency, light weight, The effect of reducing the gray speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

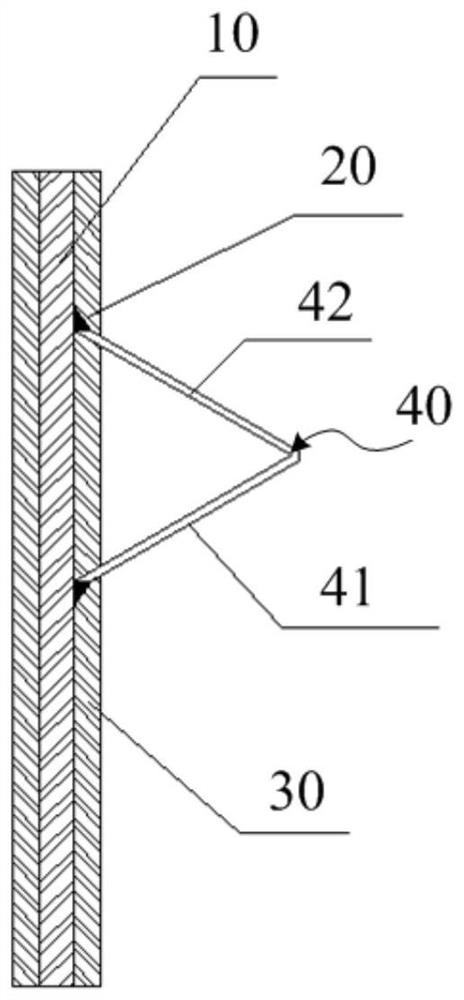

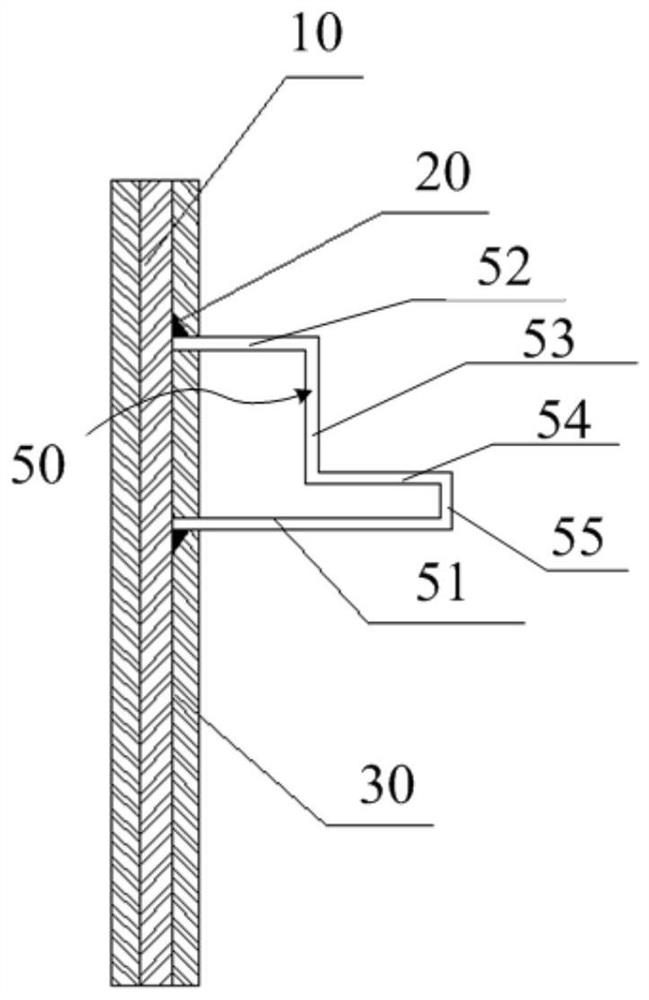

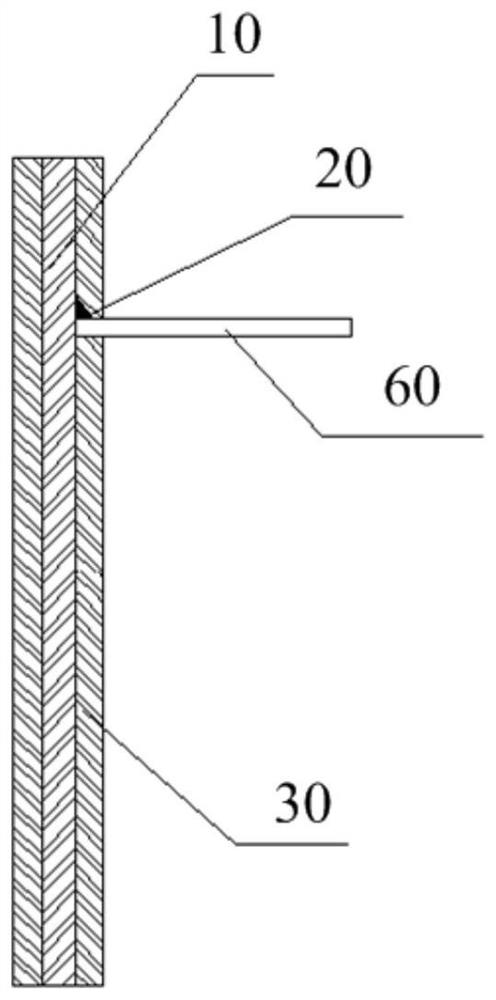

[0040]In the process of realizing the technical solution of this embodiment, the inventors found that different structures of anti-wear beams have different effects on the anti-wear effects of water-cooled walls. Decrease speed, thereby reducing the erosion and wear of particles on the water wall. Generally, the material of the water wall is mostly castable, which seriously affects the heat transfer of the water wall and the combustion in the furnace. For this reason, this embodiment provides an anti-wear device for the water-cooled wall of a circulating fluidized bed. The two sides of the water-cooled wall tube of the circulating fluidized bed are respectively provided with fins, and the fins are arranged on the circulating fluidized bed. The surface of the bed water wall tube, the anti-wear device includes:

[0041] Multiple anti-wear blocks respectively connected to the water wall of the circulating fluidized bed;

[0042] Each anti-wear block is made of stainless steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com