Dynamic crack leaking stoppage evaluation experiment device and experiment method

An experimental device and fracture technology, which can be used in earth-moving drilling, production of fluids, wellbore/well components, etc., and can solve the problem of not being able to simulate the dynamic changes of shale fractures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1 provides an experimental device for evaluating dynamic fracture plugging, and its structure will be described in detail below.

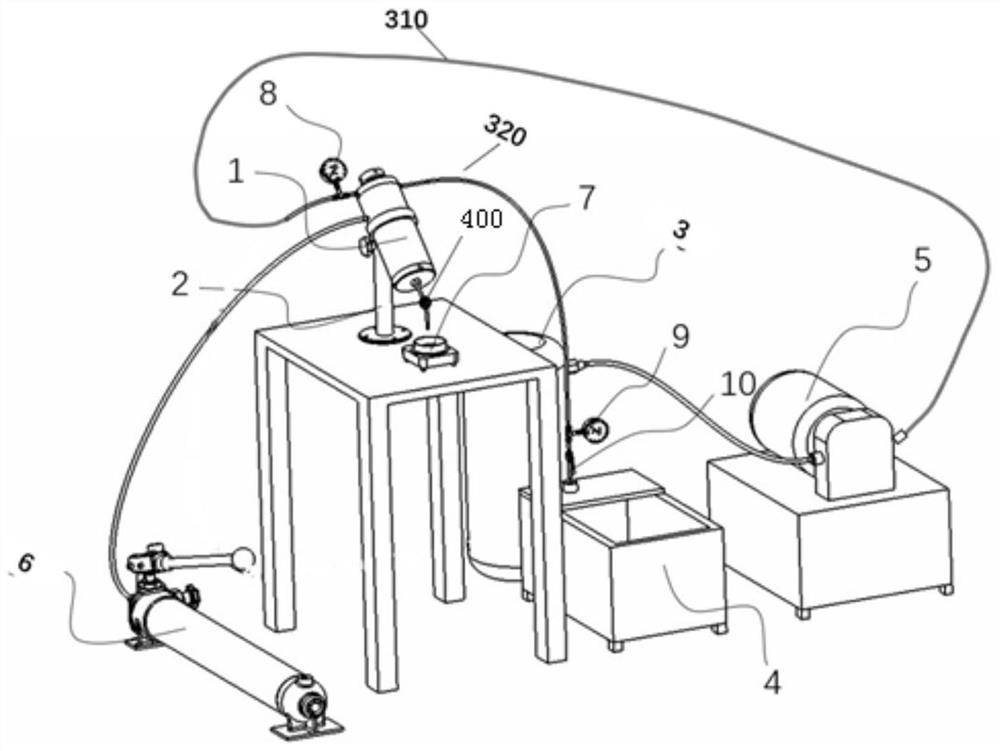

[0058] refer to figure 1 , the experimental device includes a crack simulation test instrument 1, a crack simulation test instrument fixing device 2, a liquid storage tank 3, a recovery tank 4, a hydraulic pump 5, a hand pump 6, a weighing electronic balance 7, an inlet pressure gauge 8, and an outlet pressure gauge Table 9. First back pressure valve 10 and second back pressure valve 400.

[0059] The liquid outlet of the liquid storage tank 3 is connected with the liquid inlet of the hydraulic pump 5 through a pipeline, and the liquid outlet of the hydraulic pump 5 is connected with the liquid inlet 31 of the crack simulation experiment instrument 1 through an input pipeline 310;

[0060] An inlet pressure gauge 8 is provided on the input pipeline 310;

[0061] The liquid outlet 32 of the crack simulation tester 1 is connecte...

Embodiment 2

[0088] Embodiment 2 provides an experimental method for sealing cracks with a liquid medium to obtain dynamic changes in fractures. The experimental device for evaluating dynamic crack plugging in Embodiment 1 is used, and clean water or plugging slurry is used to plug cracks to promote dynamic changes in fractures to obtain dynamic changes in fractures. process method, specifically including the following steps:

[0089] Step A: Assembling the crack simulation tester 1;

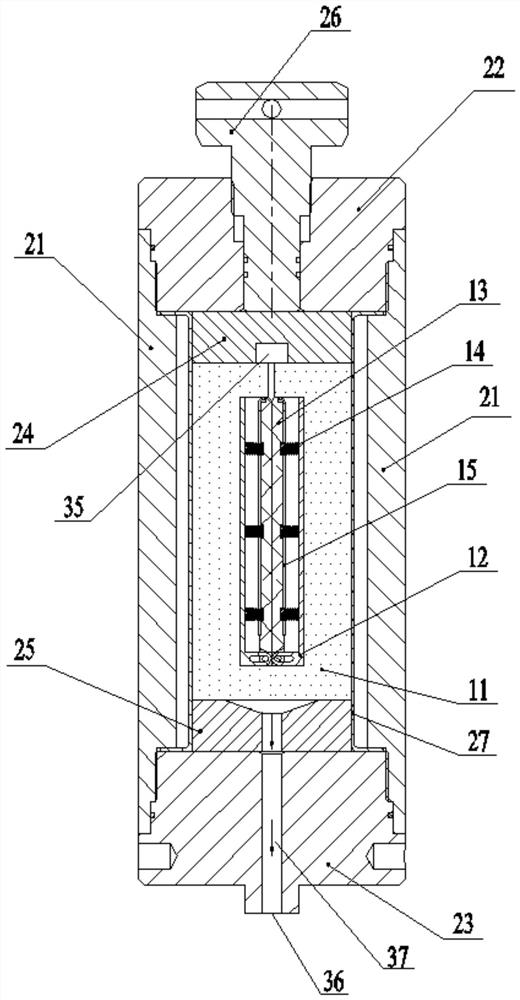

[0090] Step A1: Assemble the rock mass sample 11, the fixed plate 12, two slit plates 13, multiple sets of springs 14 and sealing rubber sleeves 15 into a dynamic crack simulation mechanism;

[0091] Step A2: Put the lower plug 25, the dynamic crack simulation mechanism, and the upper plug 24 into the rubber sleeve 27 in sequence, and assemble into the crack simulation experiment apparatus 1;

[0092] Step A3: screwing the upper cover 22 and the lower cover 23 to make the rock mass sample 11 generate axial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com