Flat knitting machine automatic stop system and control method thereof

A control method and technology of flat knitting machines, which are applied in textiles, papermaking, knitting, etc., can solve problems such as shutdown alarm failure, insulation on the surface of the stop bar, and false alarms of overlapping foreign conductive objects, and achieve fast shutdown alarm response, sensitive monitoring, and Quick and accurate shutdown alarm response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

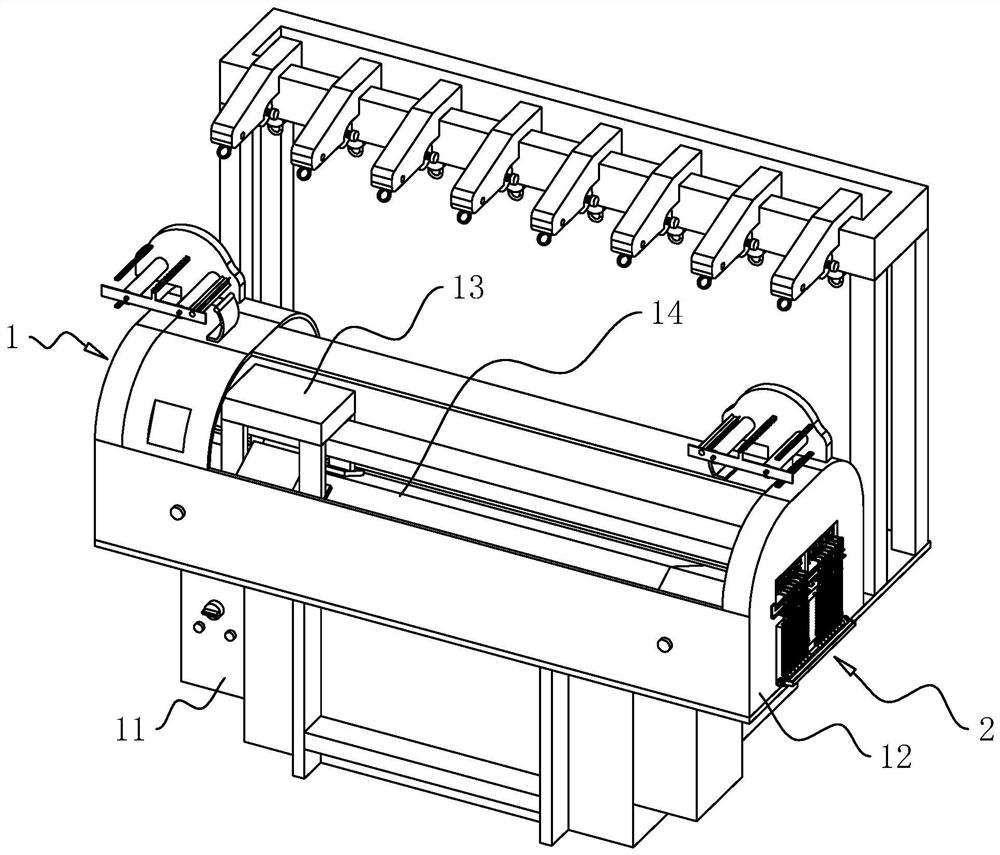

[0074] as attached figure 1 As shown, a flat knitting machine self-stop system includes a flat knitting machine 1 and an edge frame 2.

[0075] Wherein the flat knitting machine 1 comprises a base 11 at the bottom and a working room 12 installed above the base 11, and a yarn guide 13 and a needle plate 14 for weaving are installed in the working room 12. The yarn guide 13 slides on the needle plate 14 in the working chamber 12, pushes out the needle on the needle plate 14 and retreats, and knits the yarn.

[0076] as attached figure 2 As shown, the upper end of the side of the working chamber 12 is provided with a wire inlet 121 communicating with the inside and outside of the working chamber 12, so that the yarn can be passed into the working chamber 12. The size and shape of the thread inlet 121 can be determined according to actual design requirements, such as the number of yarns entering.

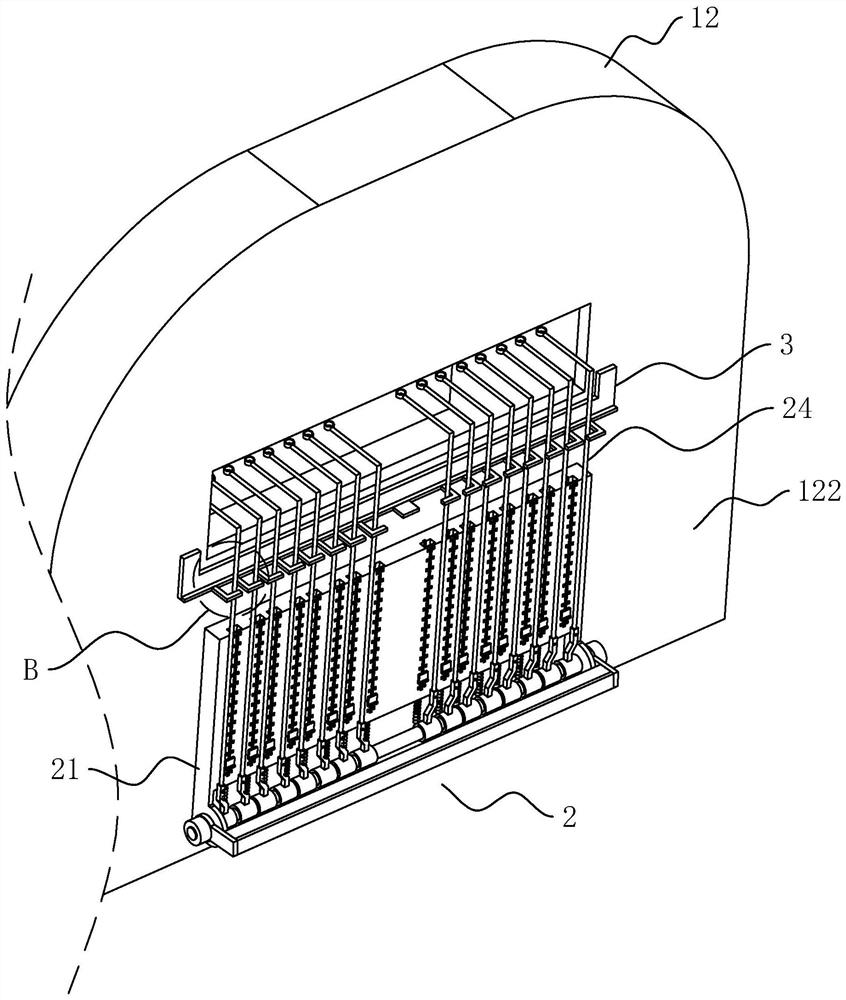

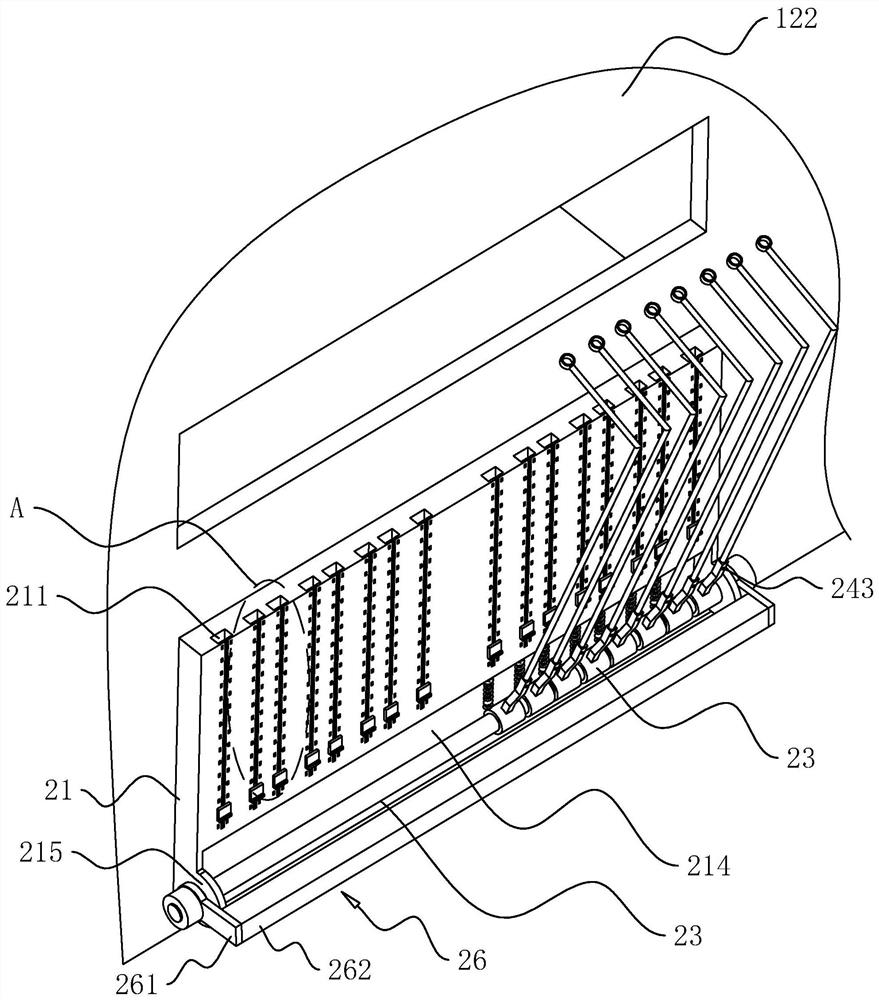

[0077] The edge frame 2 is fixed on the side of the working room 12 with the wi...

Embodiment 2

[0107] A flat knitting machine self-stop control method, based on the system of embodiment 1.

[0108] During work, yarn is worn in the wire loop 246 and the yarn supply direction is from the outside of the flat knitting machine 1 toward the interior of the flat knitting machine 1,

[0109] The upper end of the jumper 24 is only pulled by the yarn against the rotating shaft 23 except its own gravity, and it falls away from the frame body 21.

[0110] Its control steps are as follows:

[0111] S1: When the yarn is broken due to a work failure, the jumper 24 corresponding to the broken yarn loses yarn traction and turns toward the monitoring rod 262,

[0112] S2: The jumping rod 24 gradually approaches the monitoring rod 262, the magnetic sensor 2621 approaches the magnetic change threshold with the magnetic part 243, outputs a stop signal, and the flat knitting machine 1 stops.

[0113] For this control method, the magnetic field change induction is used to activate the shutd...

Embodiment 3

[0115] as attached Figure 10 As shown, a flat knitting machine self-stop system is further improved on the basis of Embodiment 1, and further includes a fault counting component 4 .

[0116] The fault counting assembly 4 includes counters 41 equal in number to jumpers 24 , and the counters 41 are installed on the installation side 122 and located below the fixing frame 3 . The distribution position of indicator 41 and the distribution position of jumper 24 are one by one. Indicator 41 is positioned at the top of rotating seat 241. Simultaneously, indicator 41 is electrically connected to magnetic sensor 2621 corresponding to the axial direction of vertical rotating shaft 23. Magnetic sensor 2621 outputs electric current every time. signal, the indicator 41 also receives the electrical signal, and makes the number on the indicator 41 increase by one.

[0117] The improvement effect of this embodiment:

[0118] Record the number of times that each jumper 24 breaks the line an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com