Device for obtaining nitrogen-containing alloy by blowing nitrogen into molten metal

A liquid metal and nitrogen alloy technology, applied in the field of metal smelting, can solve the problems of unstable recovery rate, fluctuation, affecting production costs, etc., and achieve the effect of linear and stable nitrogen increment, simple and safe operation, and not easy to splash.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

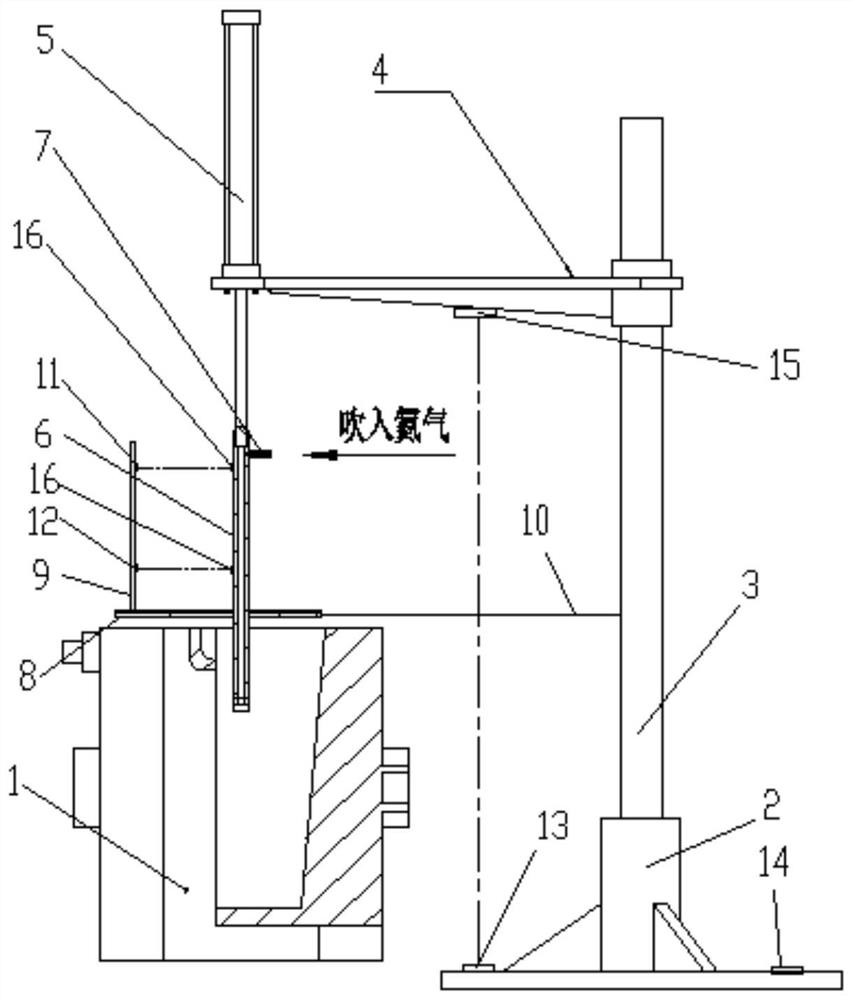

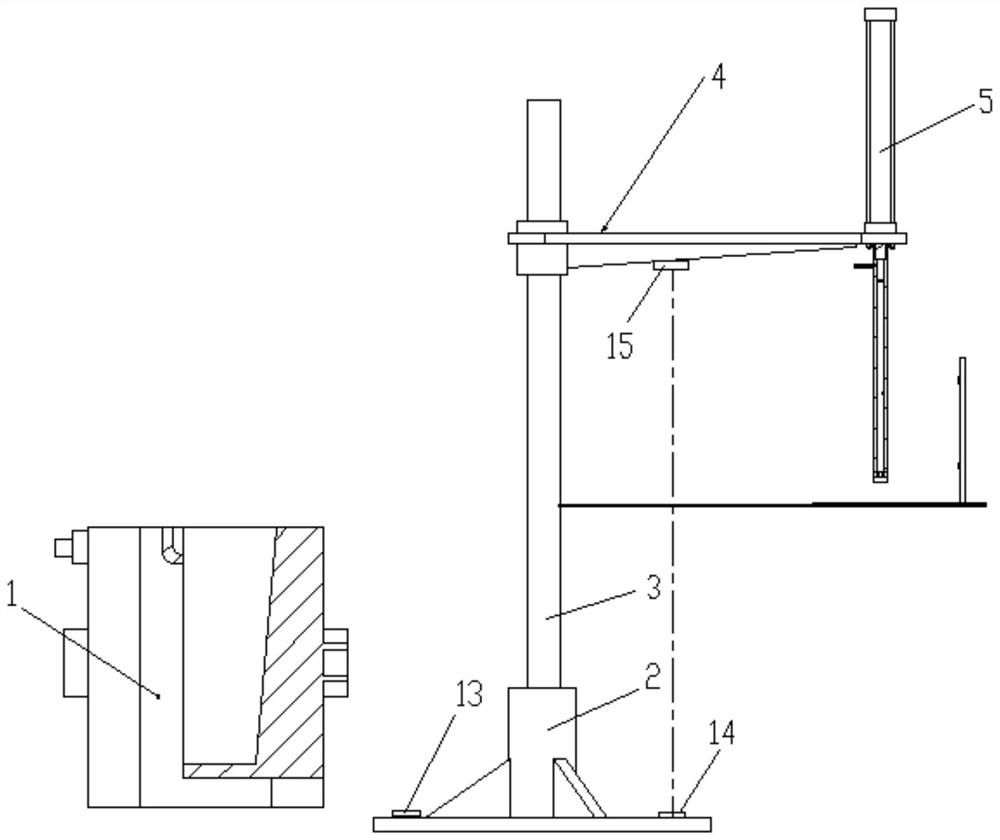

[0086] The present invention is described in detail below with reference to accompanying drawing and embodiment:

[0087] attached Figure 1-3 It can be seen that a device for obtaining nitrogen-containing alloys by blowing nitrogen into molten metal,

[0088] It includes a melting furnace 1, a supporting base 2 is arranged on the outside of the melting furnace, and a column 3 is arranged on the supporting base 2;

[0089] A support arm 4 is arranged on the column 3;

[0090] The front end of the support arm 4 is provided with a cylinder 5;

[0091] The axis of the cylinder rod is set along the vertical direction;

[0092] The front end of the cylinder rod is provided with a blowing rod 6;

[0093] The blowing rod 6 is arranged vertically;

[0094] The blowing rod is provided with an air inlet 7 along the horizontal direction;

[0095] A heat shield 8 is arranged above the smelting furnace;

[0096] The heat insulation board 8 is connected with the column through the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com