Staggered declination type sludge drying device

A drying device and sludge technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of low utilization rate of hot air, poor controllability of hot air, complex structure, etc., to save space and reduce floor space , reduce the effect of accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with accompanying drawing, and its content is explanation of the present invention rather than limitation:

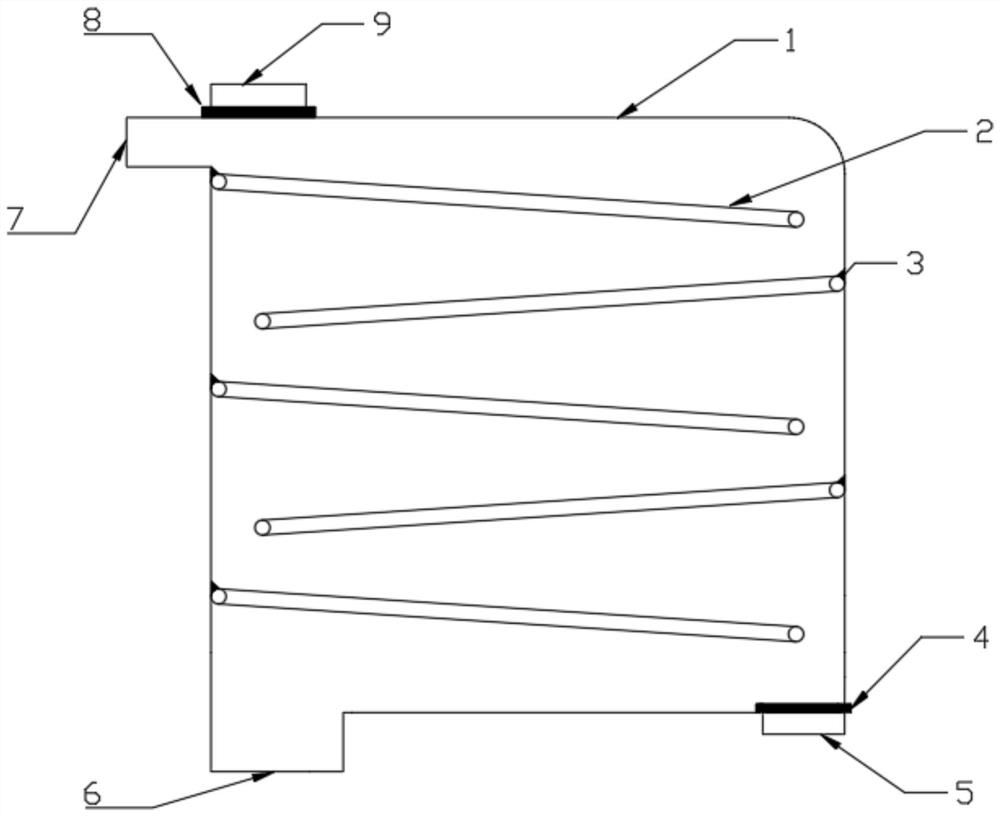

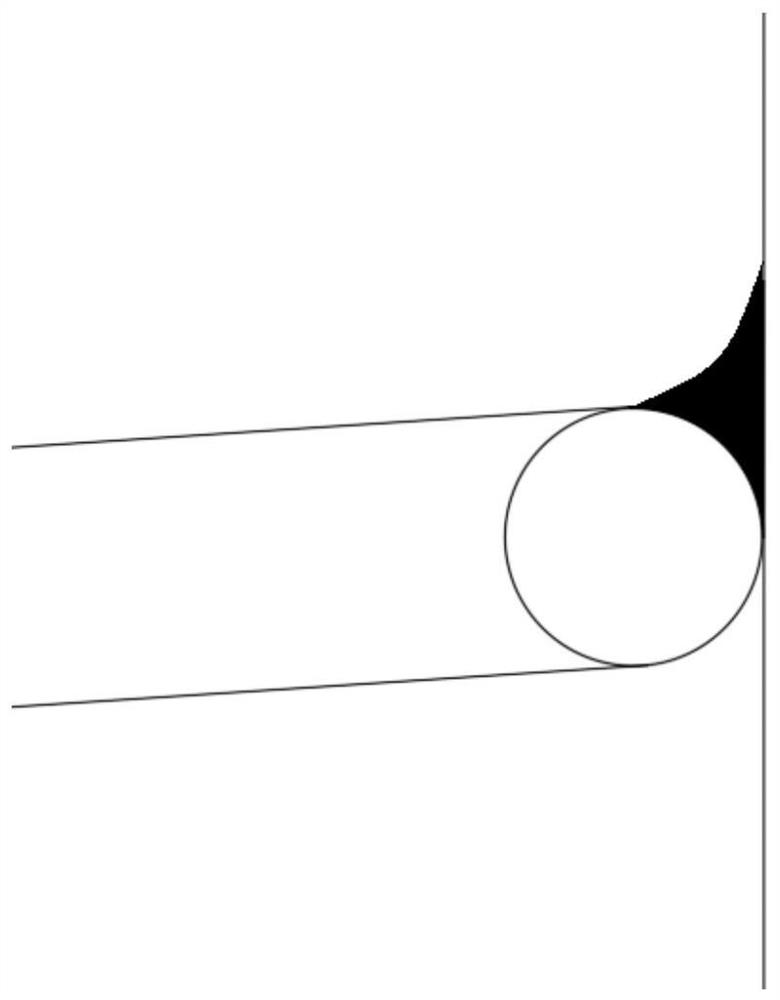

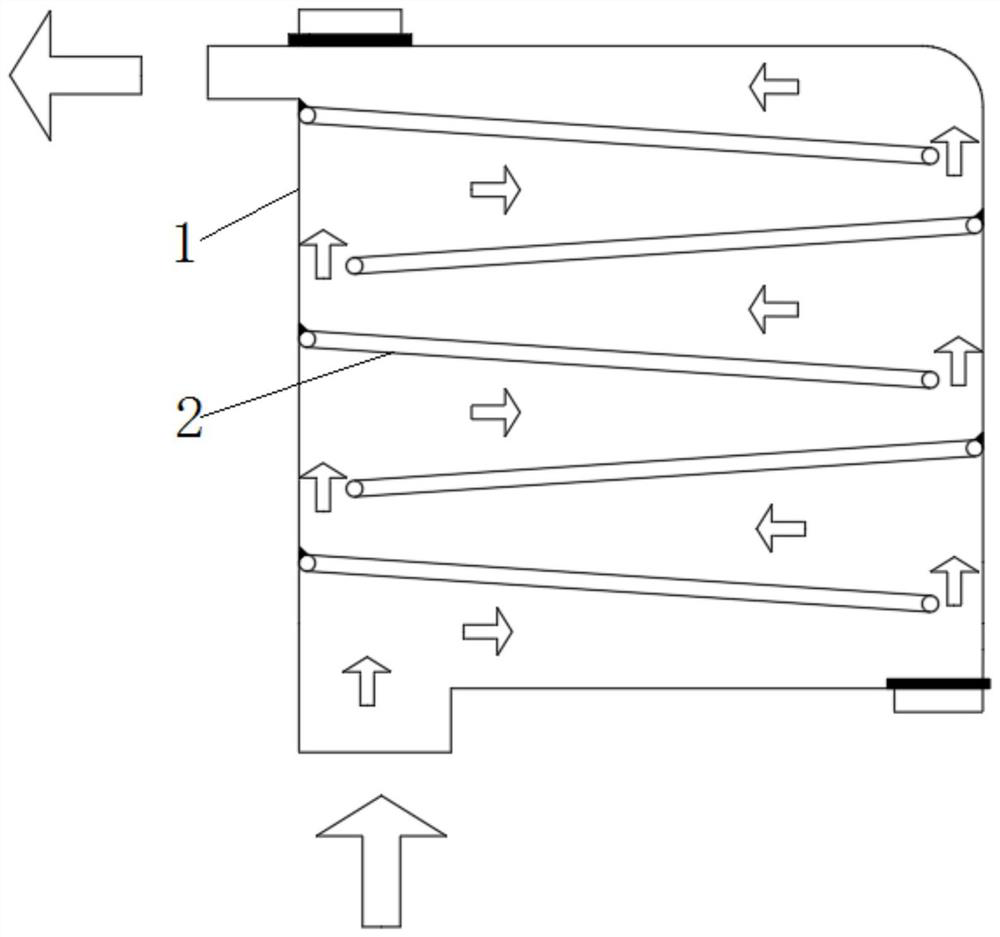

[0039] Such as figure 1 , is the staggered downward-inclining sludge drying device of the present invention. Several stages of staggered downward-inclining conveying mesh belts 2 are arranged in the drying box 1, and a large number of air holes are evenly distributed on the conveying mesh belt 2 surfaces. The drying box body 1 The upper part is provided with an air outlet 7 and a sludge inlet 9, and the bottom of the drying box 1 is provided with a sludge outlet 5 and an air inlet 6; And connect the return air treatment mechanism; the sludge feed port 9 is set above the beginning end of the uppermost conveying mesh belt 2; The discharge port 5 is located below the end of the lowest conveying mesh belt 2; the sludge discharge port 5 is provided with a discharge port valve 4, and the slud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com