Energy-saving transformation device and transformation method of steel mill wastewater treatment system

A technology for wastewater treatment system and energy-saving transformation, applied in metallurgical wastewater treatment, water/sewage treatment, chemical instruments and methods, etc. The effect of large-scale promotion and use, low cost and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

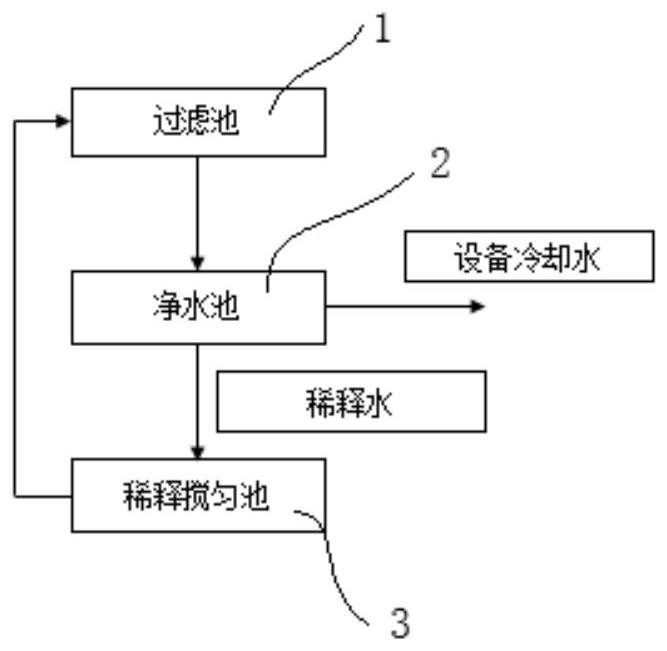

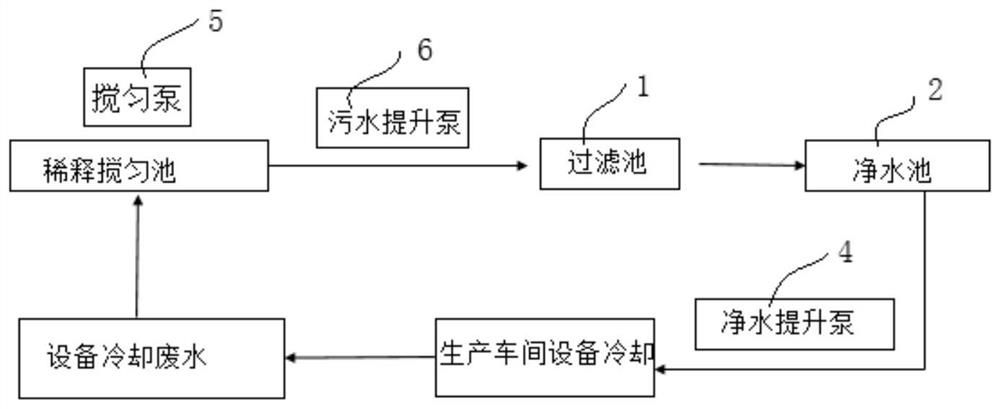

[0030] figure 1 It is a schematic diagram of the overall structure of the energy-saving transformation device in the present invention. Such as figure 1 Shown: the energy-saving retrofit device of the steel factory wastewater treatment system provided by the present invention includes a filter pool 1, a water purification pool 2, and a dilution and mixing pool 3; Arranged vertically to the bottom, the bottom surface of the filter pool 1 is flush with the ground.

[0031] The dilution and mixing pool 3 is connected with waste water to pipe, and the waste water is connected to the cooling waste water on the equipment that needs to be treated; a sewage lift pump 6 is arranged between the dilution and mixing pool 3 and the filter pool 1; the dilution and mixing pool 3 is provided with Sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com