A hydrolysis acidification reactor with slag scraping function

A hydrolysis acidification and reactor technology, which is applied in chemical instruments and methods, anaerobic digestion treatment, biological water/sewage treatment, etc. problems, to achieve the effect of improving environmental sanitation, improving wastewater treatment effect, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

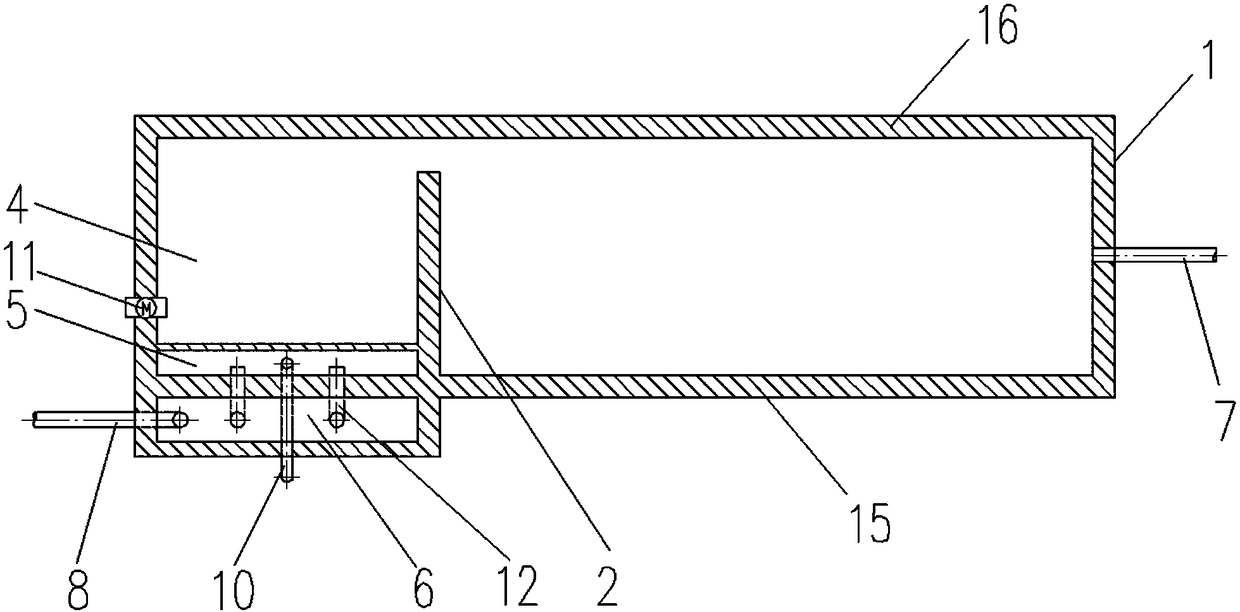

[0025] like figure 1 As shown, an exemplary hydrolytic acidification reactor with slag scraping function provided by the present invention is shown. The hydrolytic acidification reactor mainly includes: a pool body 1, in which a first Partition wall 2, one side of the first partition wall 2 joins with the front wall 15 of the pool body 1, and there is a certain distance between the other side and the rear wall 16 of the pool body 1, and the first partition wall 2 separates the pool body 1 into The plug flow packing area and the scraping slag outlet area 4; the plug flow packing area is provided with a water inlet pipe 7, the water inlet pipe 7 passes through the pool wall of the pool body 1 and connects the pool body 1 and the outside, and the sewage is passed into the hydrolysis acidification reaction through the water inlet pipe 7 In the device, the sewage is continuously passed into the pool, so that the phenomenon of push flow is formed in the hydrolysis acidification pool...

Embodiment 2

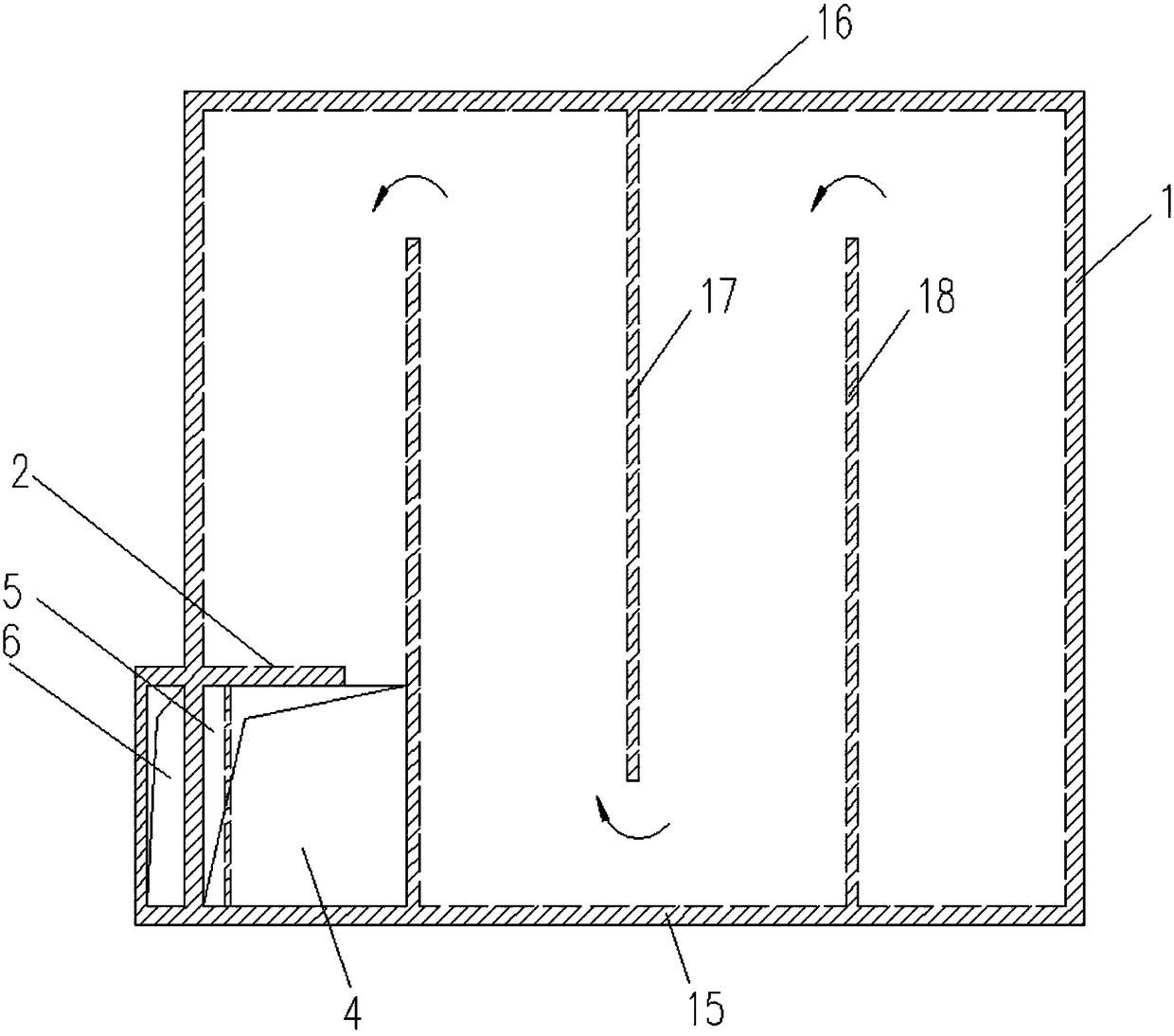

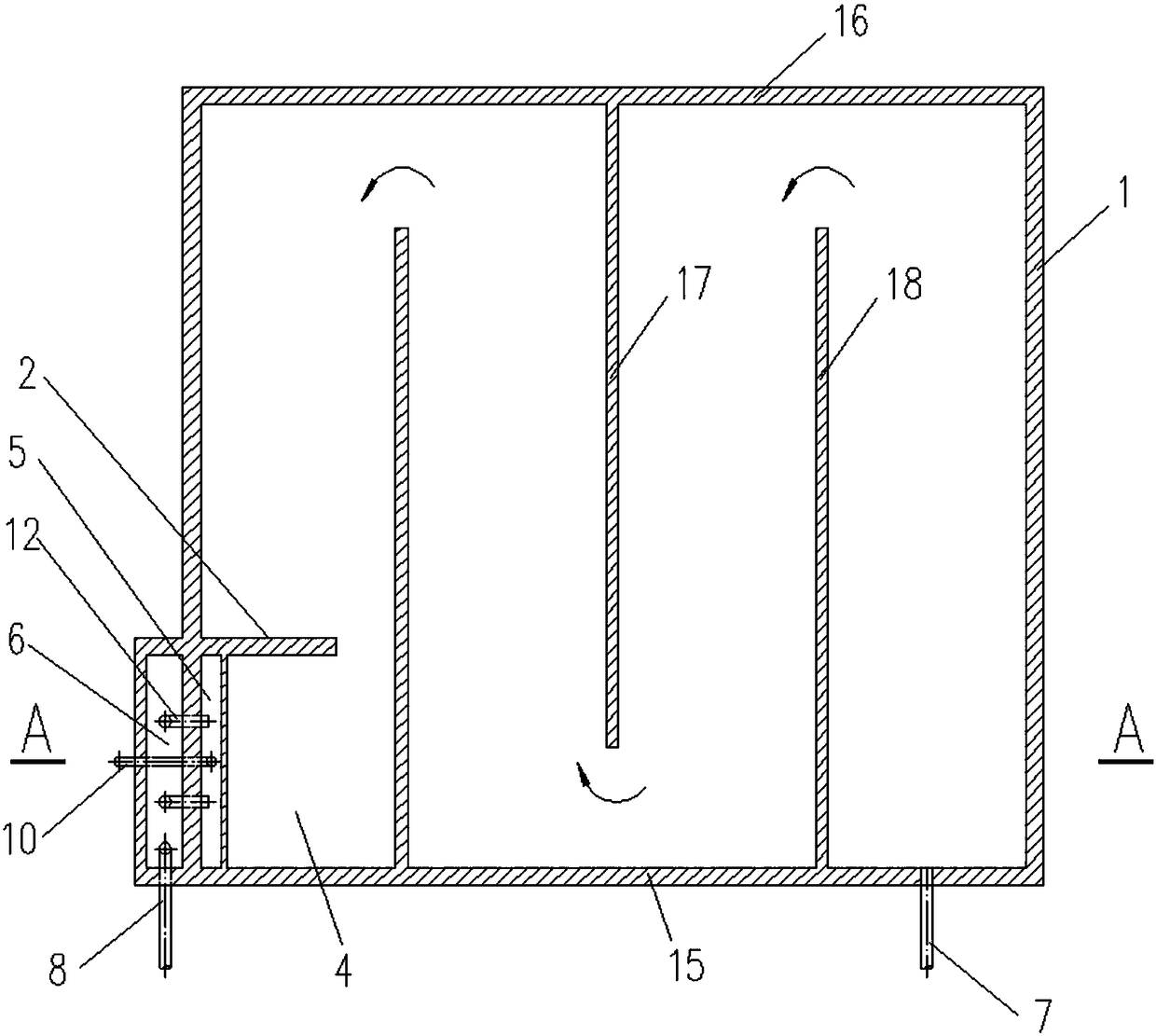

[0031] like Figure 2-Figure 4 As shown, an exemplary hydrolytic acidification reactor with slag scraping function provided by the present invention is shown. The hydrolytic acidification reactor mainly includes: a pool body 1, in which a first Partition wall 2, one side of the first partition wall 2 joins with the front wall 15 of the pool body 1, and there is a certain distance between the other side and the rear wall 16 of the pool body 1, and the first partition wall 2 separates the pool body 1 into Plug-flow packing area and scraping slag outlet area 4, at least one second partition wall 17 and at least one third partition wall 18 are arranged in the plug-flow packing area, and one side of the second partition wall 17 is in contact with the rear wall 16 of the pool body 1 There is a certain distance between the other side and the front wall 15 of the pool body 1, one side of the third partition wall 18 is connected to the front wall 15 of the pool body 1, and the other si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com