Recreational vehicle body curing process and curing equipment thereof

A curing process and curing equipment technology, which is applied in the field of RV, can solve the problems of waste of manpower, weak sandwich board structure, imperfect cooling process and reinforcement process, etc., to improve accuracy, improve production safety, and avoid flashing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

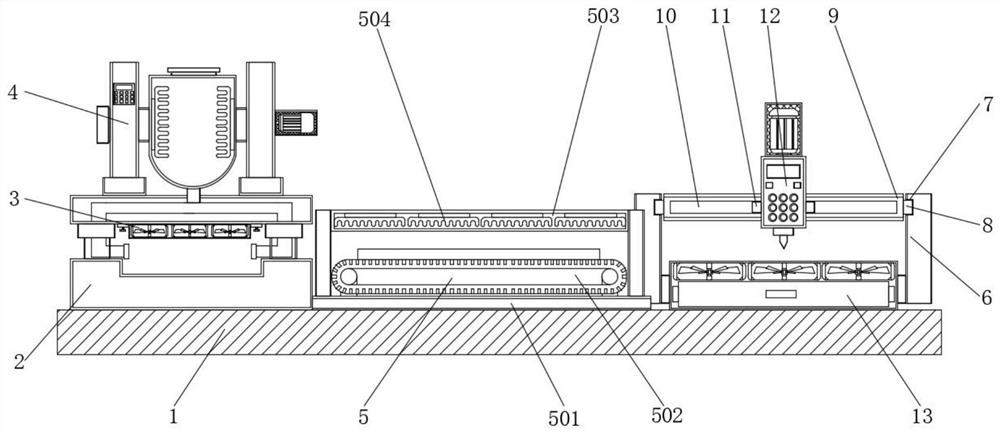

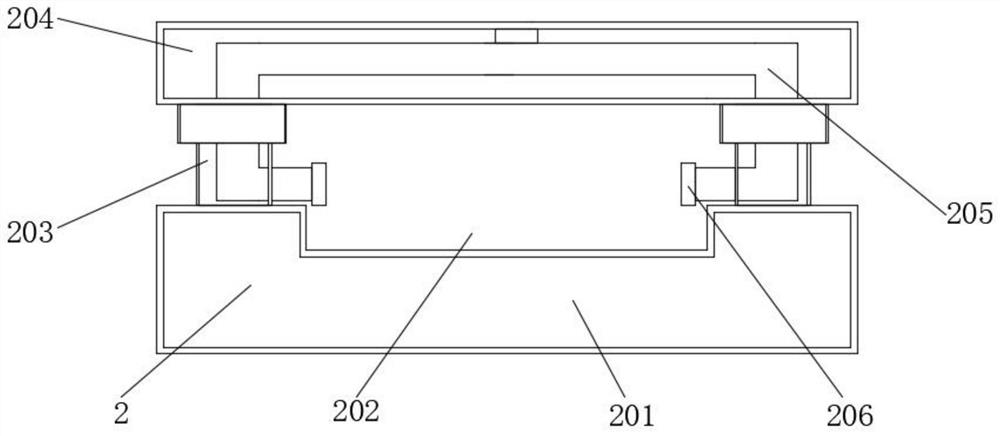

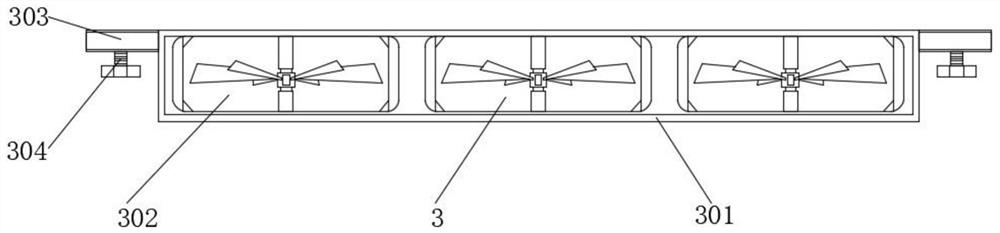

[0041] see Figure 1-6 , in this embodiment: a car body solidification process and solidification equipment thereof, including a base 1, a cooling mechanism 3, a melting mechanism 4, a transmission drying mechanism 5, a cutting mechanism 12 and a dust removal mechanism 13; the top of the base 1 is provided with a molding Mechanism 2 and cooling mechanism 3 are set on the inner side of the forming mechanism 2, the melting mechanism 4 is set on the top of the forming mechanism 2, the transmission and drying mechanism 5 is set on the outside of the forming mechanism 2, and the outside of the transmission and drying mechanism 5 is provided with a support frame 6. The inner wall of the support frame 6 is provided with a first chute 7, and the inner side of the first chute 7 is provided with a first slider 8. At the same time, the first slider 8 is installed in cooperation with the beam 9, and the inner wall of the beam 9 is provided with a The second chute 10 , and the second slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com