Bracket simulation analysis method and system

A simulation analysis and bracket technology, applied in the automotive field, can solve problems affecting bracket production and inaccurate simulation analysis results, and achieve the effects of improving design and simulation efficiency, accurate characterization, and reducing the number of design changes and simulation times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

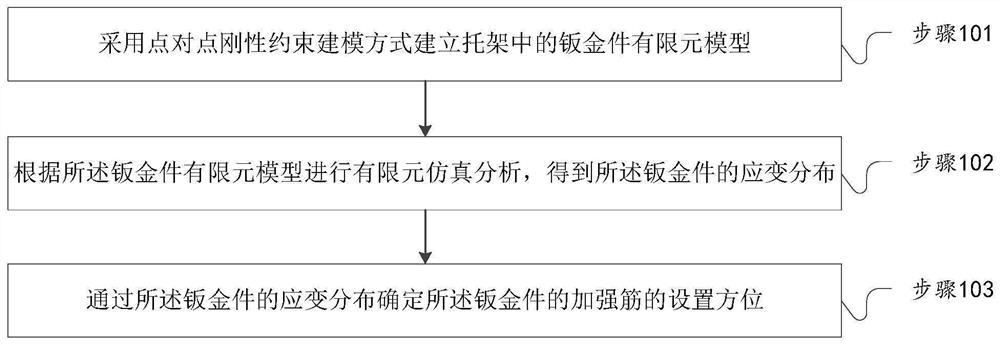

[0048] see figure 1 , the embodiment of the present invention discloses a bracket simulation analysis method, comprising the following steps:

[0049] In step 101, a point-to-point rigid constraint modeling method is used to establish a finite element model of the sheet metal part in the bracket.

[0050] Specifically, there is a welding relationship between many sheet metal parts of the bracket, but because the shell element of the existing modeling considers the thickness factor, the use of point-to-point common node modeling when establishing welds will cause sheet metal bending, which cannot reflect The original geometric features and assembly relations. In order to avoid this, thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com