Hydride heat storage system and method adopting direct illumination heating

A heat storage system and hydride technology, applied in solar heating systems, lighting and heating equipment, solar heat storage, etc., can solve the problems that restrict the practical application of chemical heat storage devices, are not suitable for large-scale use, and have complex structures. Achieve the effect of simple structure, avoid energy loss and improve heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

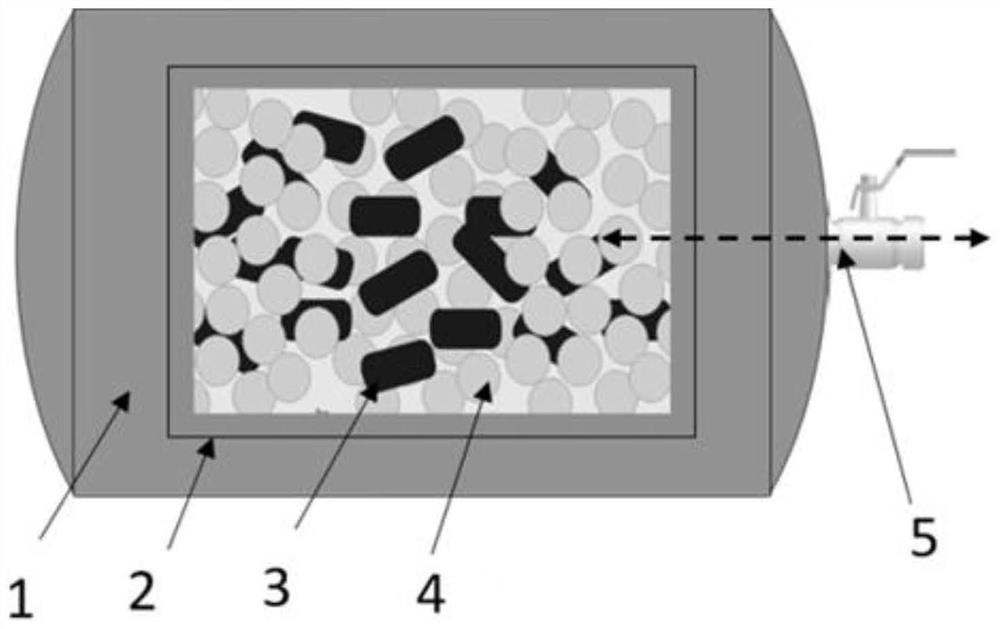

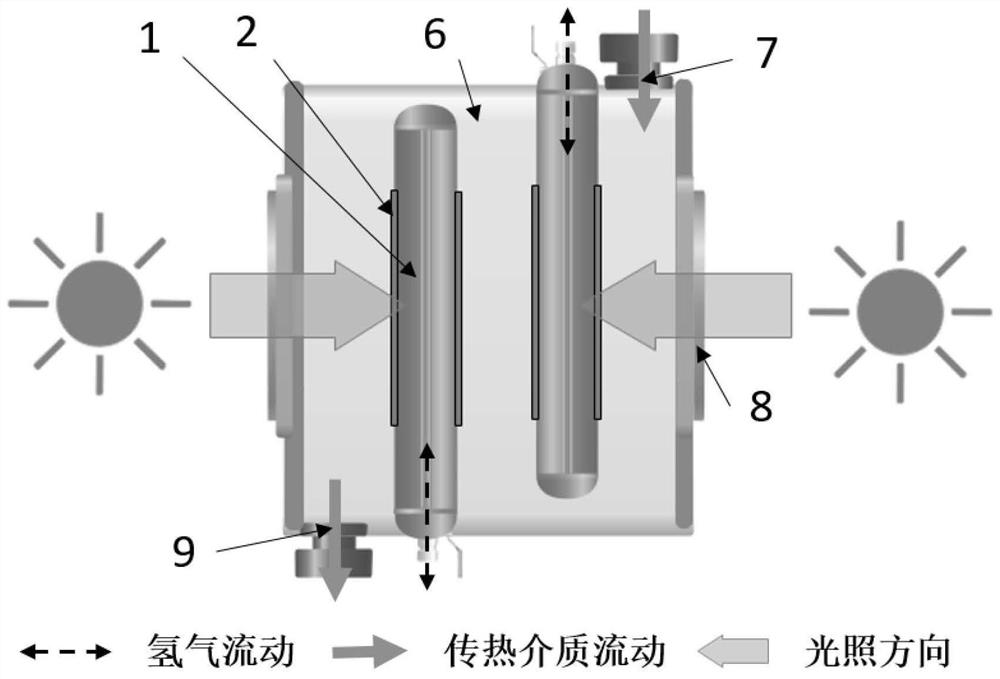

[0030] Such as figure 1 and figure 2 As shown, the present invention is a hydride heat storage system heated by direct light, including a heat exchange tank 6, and a first light-transmitting module 8 for passing sunlight is installed on both sides of the heat exchange tank 6, and the heat exchange tank 6 The inflow port 7 and the outflow port 9 for the heat exchange medium to enter and exit are respectively opened; the upper and lower inner surfaces of the heat exchange tank 6 are alternately fixed with a number of heat storage reactors 1 that play the role of baffle, and the heat storage reactors 1 One end of the heat storage reactor 1 protrudes from the heat exchange tank 6, and one end of the heat storage reactor 1 protruding from the heat exchange tank 6 is fixedly connected with a hydrogen valve 5 connected to an external hydrogen stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com