Low-permeability reservoir natural gas hydrate exploitation fracturing and sand prevention combined process method

A low-permeability reservoir and process method technology, which is applied in the field of natural gas hydrate exploitation, production stimulation and sand control, can solve problems such as unsatisfactory production stimulation and sand control effects, and achieve the effects of reducing sand-carrying velocity, improving seepage conditions, and increasing gas production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

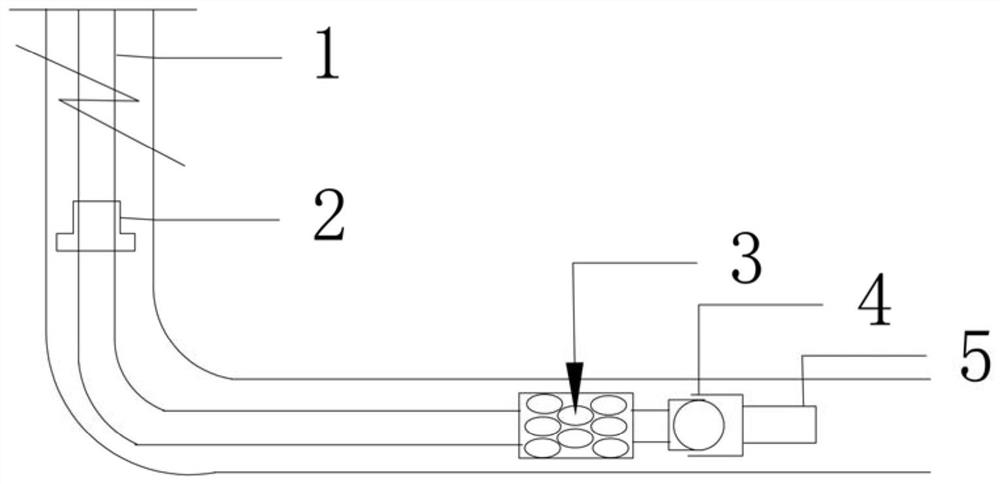

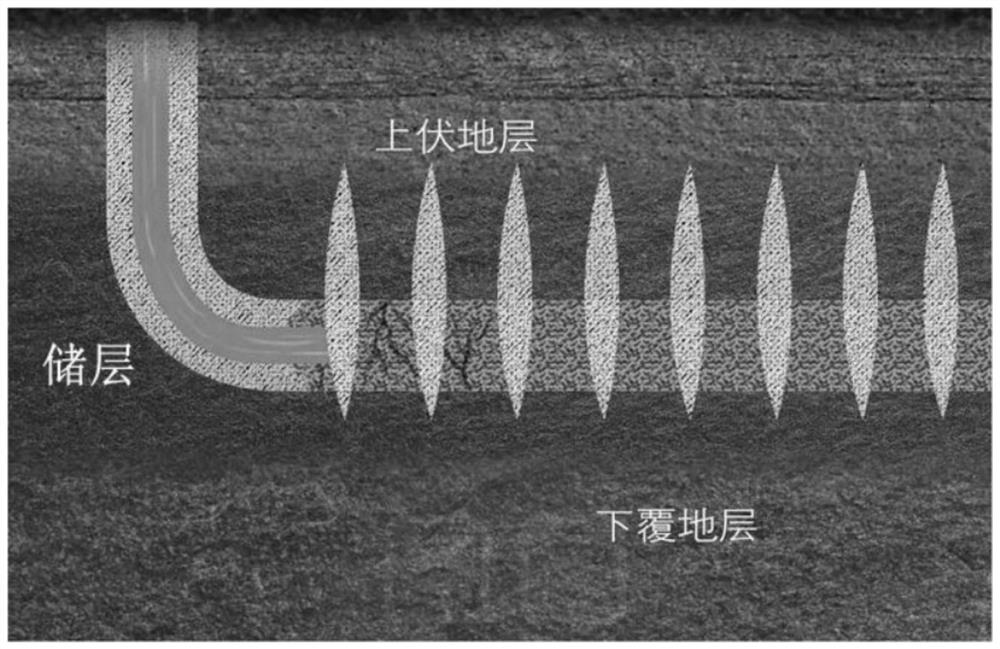

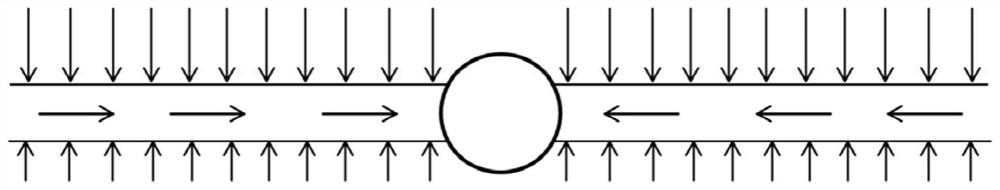

[0038] The combined hydraulic sand blasting perforation fracturing and sand control process method of the low-permeability reservoir natural gas hydrate exploitation reservoir of the present invention combines the technical characteristics of the hydraulic sand blasting perforation and fracturing gravel packing process, and uses the The hydraulic jet tool forms one (or more) injection holes in the reservoir through water hammering, thereby generating micro-fractures in the near-wellbore area, and then uses the end sand screen fracturing technology to open and extend the micro-fractures, and at the same time uses sand control The medium is filled in it to achieve sand screening at the end, forming multiple short and wide fracture zones with high conductivity capacity inside the low-permeability reservoir, and at the same time, the sand control medium filter body in the fracture plays a sand control effect of gravel packing.

[0039] Such as figure 1 As shown, the hydraulic sand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com