Electroplating method capable of automatically and continuously supplementing liquid

A liquid replenishment and automatic technology, applied in the electrolysis process, electrolysis components, current conduction devices, etc., can solve the problems of low automation, high requirements for operators' work experience, low operation efficiency, etc., and achieve a high degree of automation assembly line and manual work Low experience requirements and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

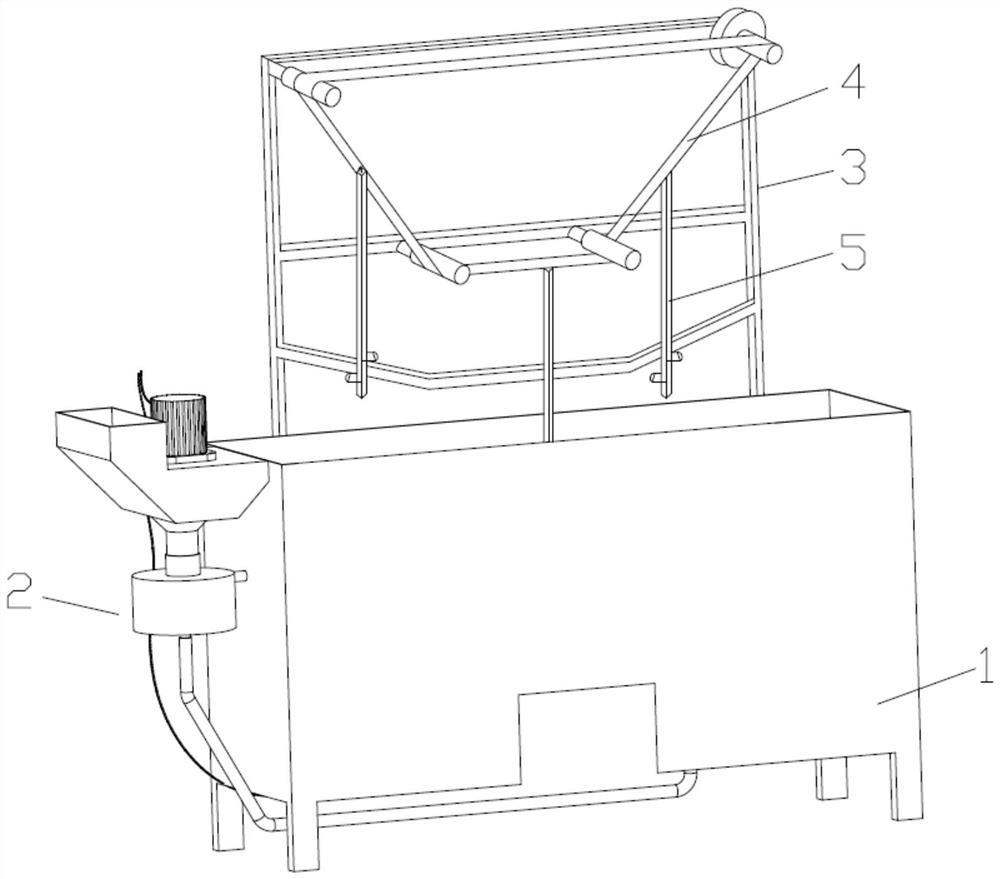

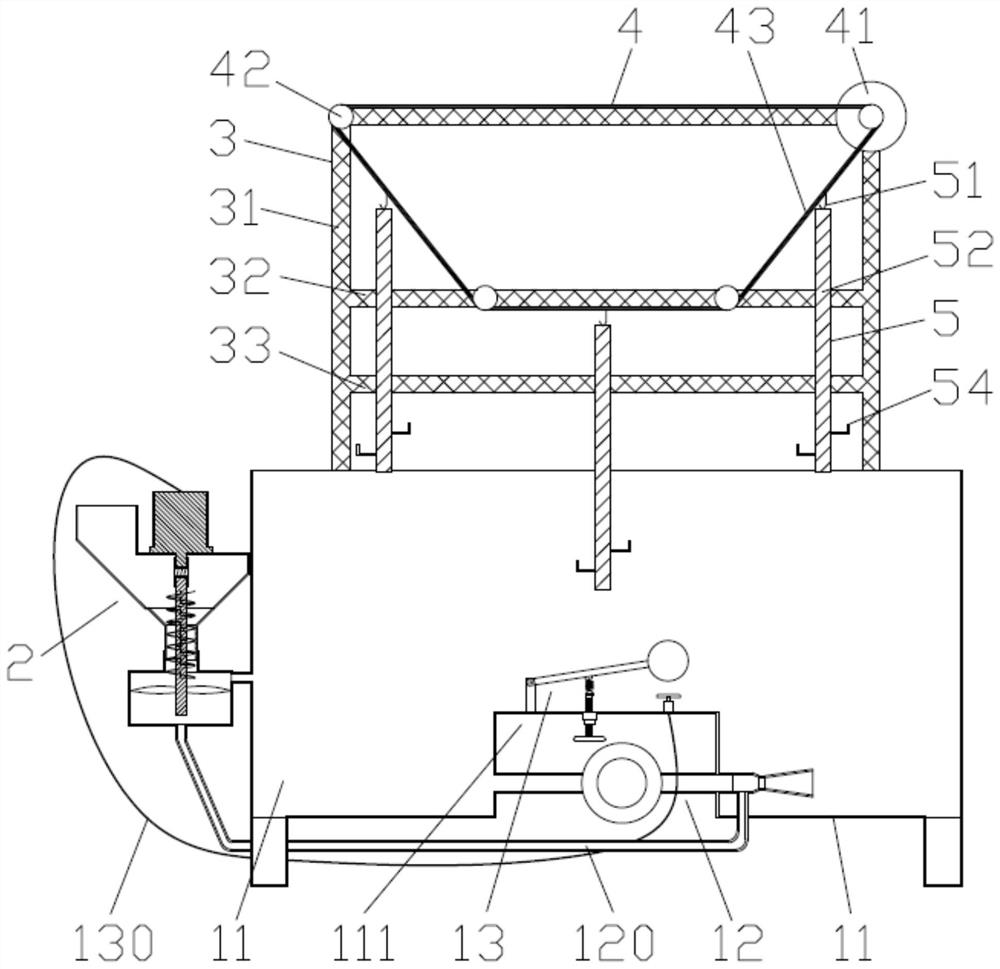

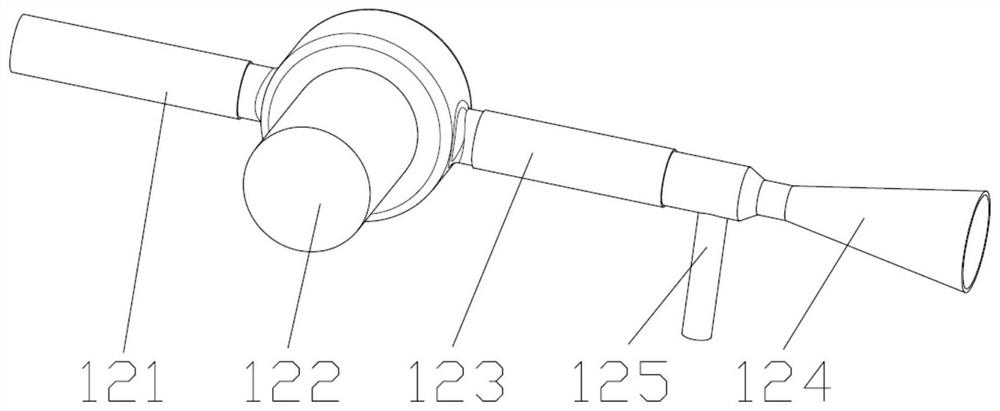

[0049] Such as Figure 1-9 As shown, an electroplating method for automatic continuous liquid replenishment is characterized in that: automatic electroplating equipment is adopted, and the automatic electroplating equipment includes electroplating pool 1, dosing device 2, electroplating support 3, transmission equipment 4 and electroplating hanger 5; electroplating support 3 Fixedly installed above the side wall of the electroplating pool 1, the transmission device 4 is installed on the side of the electroplating bracket 3 close to the electroplating pool 1, the electroplating rack 5 is installed on the transmission device 4, and the electroplating rack 5 is controlled by the transmission device 4 to approach or Moving in the direction away from the electroplating pool 1, the dosing device 2 is arranged on the other side of the electroplating pool 1 (that is, on a different side from the electroplating support), and communicates with this side of the electroplating pool 1;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com