Lightweight grouting material for repairing hollowing of wall thermal insulation system and preparation method

A grouting material and system technology, applied in the field of building materials, can solve the problems of poor durability, poor water resistance, large volume and weight of chemical grouting materials, improve later strength and volume stability, excellent performance and simple production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046]The preparation method of lightweight grouting material includes the following steps:

[0047]Step 1. Weigh various raw materials according to weight ratio;

[0048]Step 2: Add the weighed ternary cementitious material and auxiliary cementitious material into the coulter mixer and mix for 1min-2min;

[0049]Step 3. Add the weighed latex powder, cellulose ether, water reducing agent, air-entraining agent, defoamer, water repellent and expansion agent together into the coulter mixer and mix for 2min-3min;

[0050]Step 4. Finally, the weighed lightweight aggregate and quartz sand are added to the coulter mixer and mixed for 60s-90s to prepare a lightweight grouting material for hollow repair of the wall insulation system.

[0051]When in use, add water to the light grouting material, the amount of water added is 18%-21% of the total weight of the light grouting material, the specific steps are as follows: pour the weighed light grouting material into the forced mixer, and stir at the same time ...

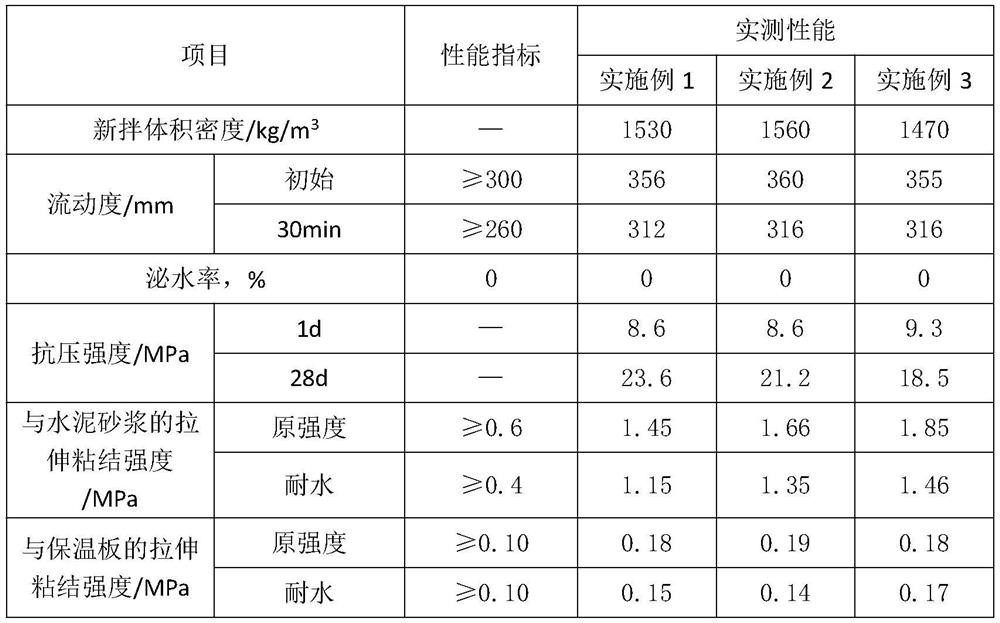

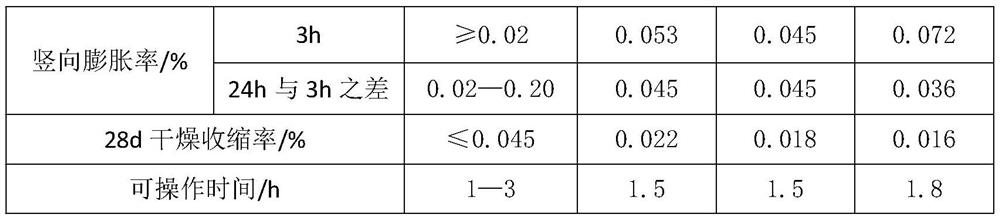

Embodiment 1

[0054]A lightweight grouting material for hollow repair of wall insulation system, according to ternary cementing material 100, auxiliary cementing material 15, latex powder 8, cellulose ether 0.03, water reducing agent 0.3, air-entraining agent 0.15, defoaming It is prepared by weight ratio of agent 0.2, water repellent agent 0.6, expansion agent 0.04, light aggregate 3 and quartz sand 138.

[0055]First add the weighed ternary gelling material and auxiliary gelling material to the coulter mixer and mix for 1 min; then add the weighed latex powder, cellulose ether, water reducing agent, air-entraining agent, defoamer, The water-repellent agent and the expansion agent are added to the coulter mixer and mixed for 2 minutes; finally, the weighed lightweight aggregate and quartz sand are added to the coulter mixer and mixed for 60 seconds to prepare the wall insulation system. Use lightweight grouting materials.

[0056]Add water at 19% of the total weight of the lightweight grouting materia...

Embodiment 2

[0058]A lightweight grouting material for hollow repair of wall insulation system, according to ternary gelling material 100, auxiliary gelling material 20, latex powder 10, cellulose ether 0.04, water reducing agent 0.3, air-entraining agent 0.2, defoaming It is prepared by weight ratio of agent 0.3, water repellent agent 0.5, expansion agent 0.03, light aggregate 4, and quartz sand 180.

[0059]First add the weighed ternary gelling material and auxiliary gelling material to the coulter mixer and mix for 1 min; then add the weighed latex powder, cellulose ether, water reducing agent, air-entraining agent, defoamer, The water repellent and the expansion agent are added to the coulter mixer and mixed for 2 minutes; finally, the weighed lightweight aggregate and quartz sand are added to the coulter mixer and mixed for 75 seconds to prepare the wall insulation system Use lightweight grouting materials.

[0060]Add water at 18% of the total weight of the lightweight grouting material, and sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com