Application of catalyst taking waste adsorbent after adsorption-desorption as raw material in treatment of high-salt organic wastewater by activating persulfate

A technology for activating persulfate and organic wastewater, which is used in oxidation water/sewage treatment, physical/chemical process catalysts, water/sewage treatment, etc. Difficult to use, no treatment methods, etc., to achieve high ability to activate persulfate, ease the pressure of solid waste disposal, and improve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

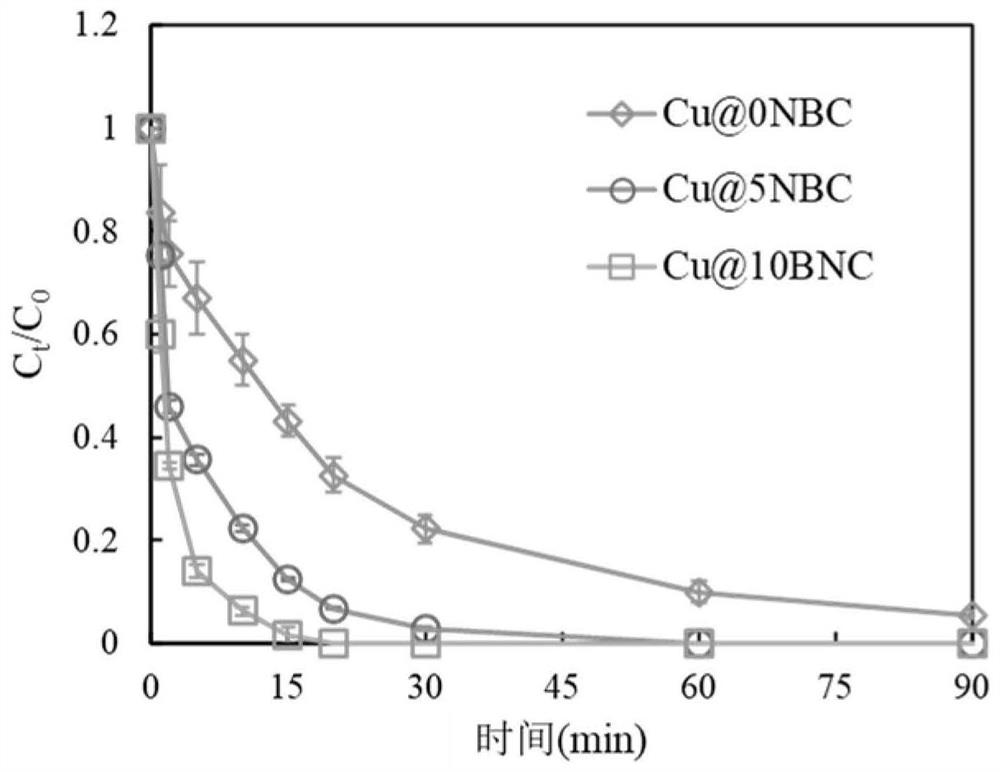

[0050] The catalyst using the waste adsorbent after adsorption-desorption as raw material is applied in the treatment of high-salt organic wastewater by activating persulfate, including the following steps:

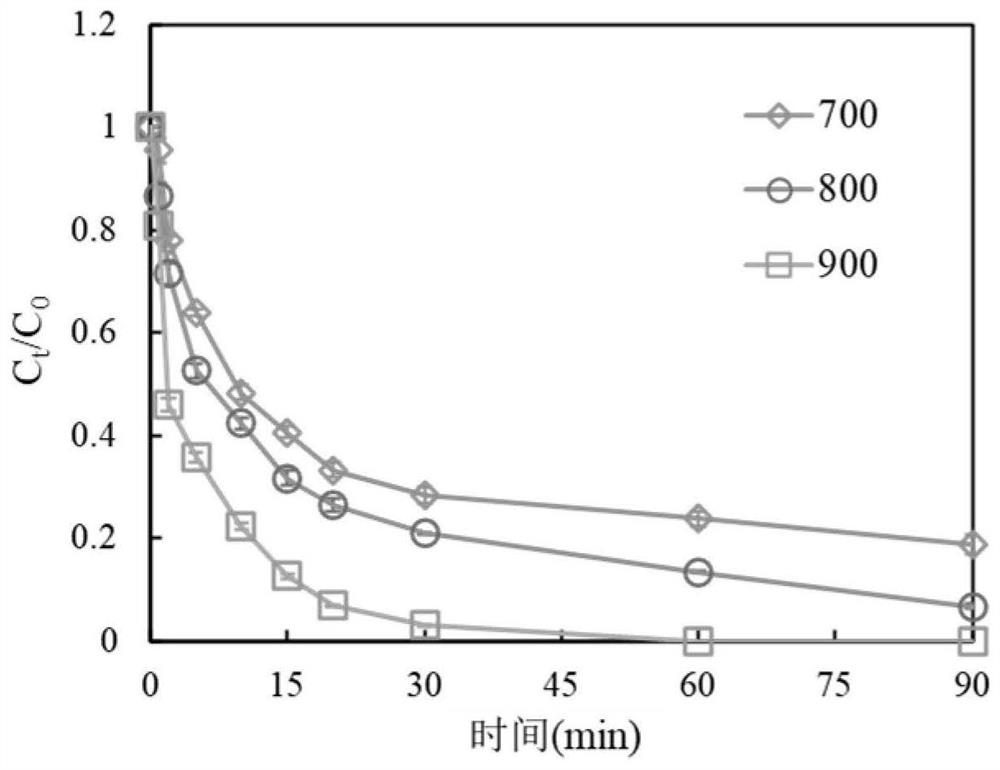

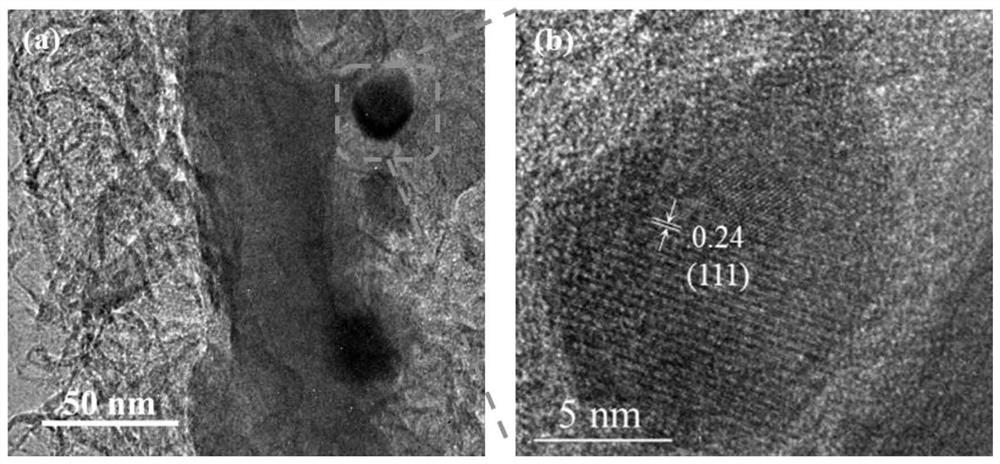

[0051] (1) Dry the waste biomass adsorbent after 8 times of adsorption-desorption of Cu ions, take 10 g of the dried waste adsorbent, mix it according to the mass ratio of waste adsorbent: dicyandiamide 1:5, and put it into a porcelain boat Compact it, put it into a tube furnace, heat it up to 900°C at a rate of 10°C / min under a nitrogen atmosphere for pyrolysis, keep it warm for 2 hours and then bring it to room temperature, take it out and wash it with deionized water, and finally put it at 60°C drying to obtain the spent adsorbent-based catalyst;

[0052] (2) Add the waste adsorbent-based catalyst into the high-salt organic wastewater, and add persulfate at the same time. The dosage of persulfate is 0.2g / L. React for 90 minutes to degrade and remove persistent organic...

Embodiment 2

[0054] The catalyst with the discarded adsorbent after adsorption-analysis as raw material described in Example 1 is used in the treatment of high-salt organic wastewater with activated persulfate, the difference is that the mass ratio of the discarded adsorbent to dicyandiamide is 1 :0.

Embodiment 3

[0056] The catalyst with the discarded adsorbent after adsorption-analysis as raw material described in Example 1 is used in the treatment of high-salt organic wastewater with activated persulfate, the difference is that the mass ratio of the discarded adsorbent to dicyandiamide is 1 :10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com