Application of phosphate to promotion of green rust to activate molecular oxygen

A phosphate and patina technology, applied in chemical instruments and methods, special compound water treatment, oxidized water/sewage treatment, etc., to achieve cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

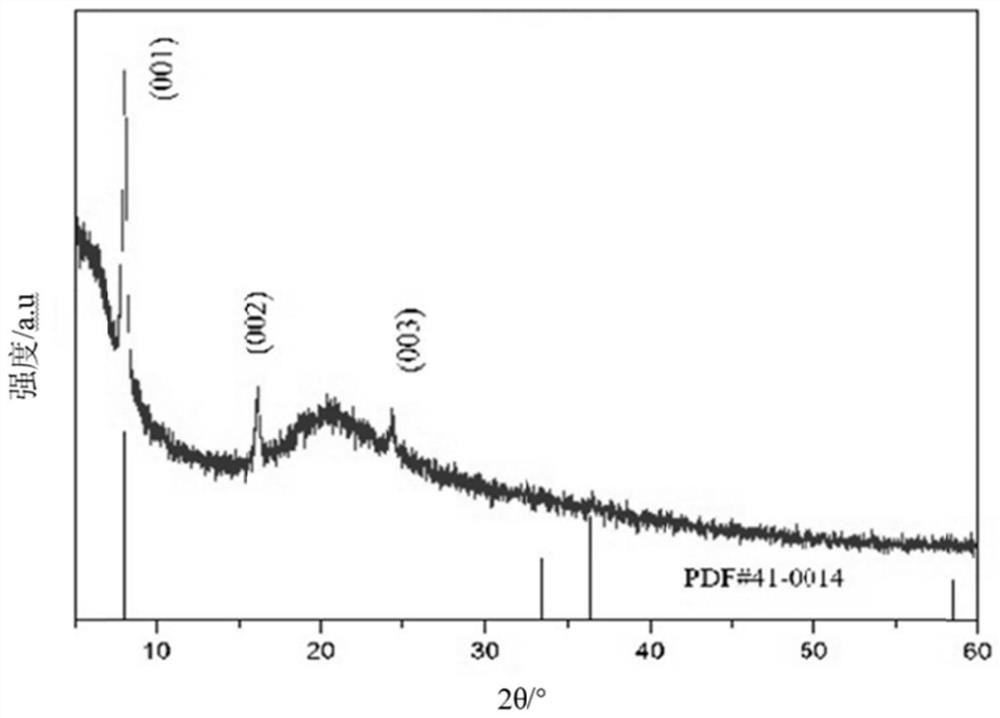

[0064] The preparation of embodiment 1 green rust-phosphate complex

[0065] (1) Add 2g of ferrous sulfate heptahydrate directly into 10mL of NaOH solution (1mol / L), stir evenly with a glass rod and put into a 6cm magnetic rotor; then add 90mL of deionized water to obtain 100mL of Fe(OH) 2 Suspension, and carry out magnetic stirring, stirring speed is 400 rpm;

[0066] (2) Open and stir to make Fe(OH) 2 Partial oxidation, measure the molar ratio of ferrous iron to ferric iron in the suspension during stirring, when the molar ratio of ferrous iron to ferric iron in the suspension is 2.5:1, stop the reaction, and then in an oxygen-free environment Continue stirring to remove O from the suspension 2 , to obtain sulfate radical intercalation green embroidered, immediately transferred to a 250mL blue cap bottle, and then transferred to an anaerobic glove box to prevent the patina from continuing to oxidize, separated by filtration, dried and stored in anaerobic conditions;

[00...

Embodiment 2

[0068] The preparation of embodiment 2 green rust-phosphate complex

[0069] The preparation method of complex body in the present embodiment is consistent with embodiment 2, difference only lies in step (3), specifically as follows:

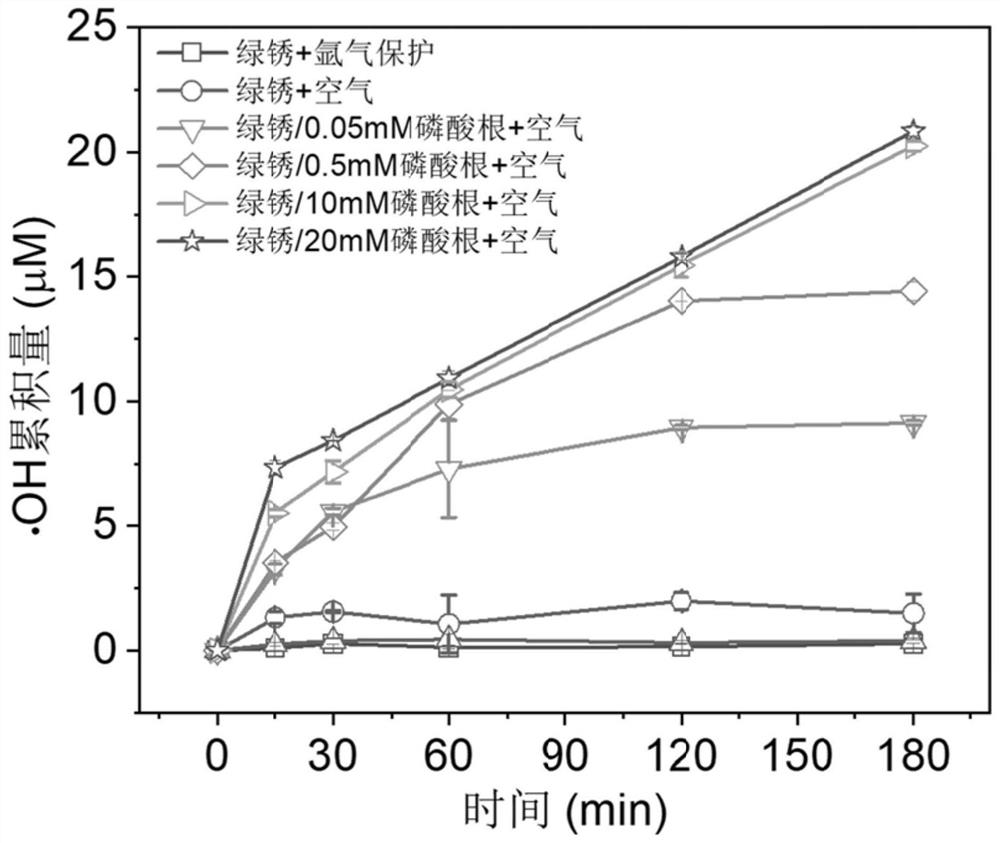

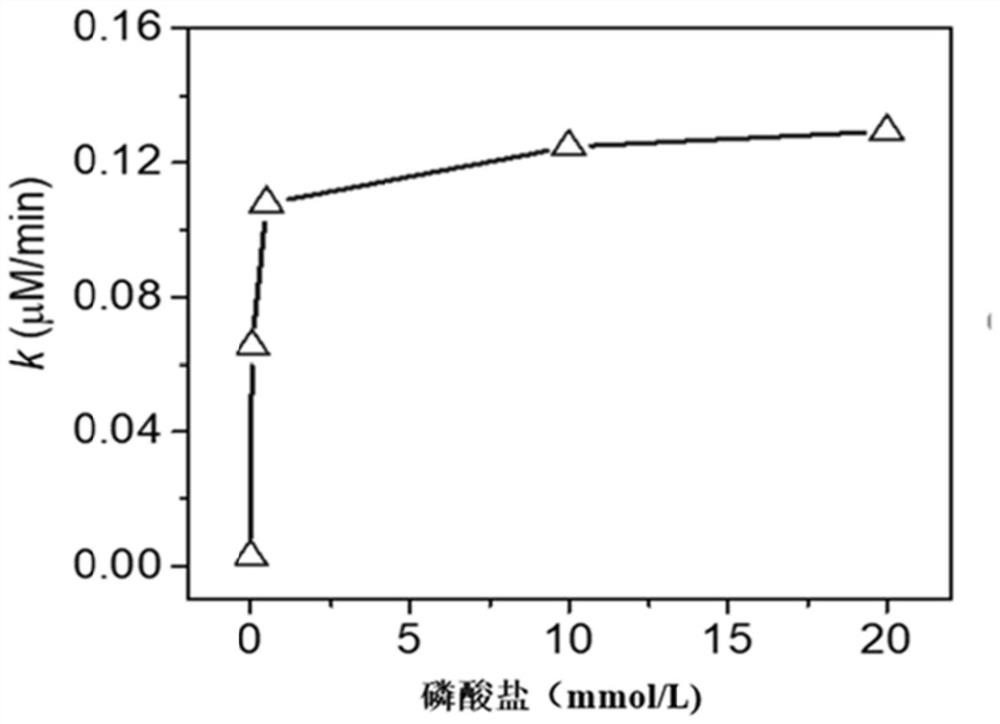

[0070] (3) get patina 50mg that step (2) obtains, add 0.5mmol / L sodium hydrogen phosphate aqueous solution 100mL, the final concentration of patina is 0.5g / L, the iron element in the patina and the phosphorus element in the sodium hydrogen phosphate The molar ratio of Fe / P was 8:1. After fully stirring, the pH was adjusted to 7.5 to obtain a patina-phosphate complex suspension with a Fe / P molar ratio of 8:1.

Embodiment 3

[0071] The preparation of embodiment 3 green rust-phosphate complex

[0072] The preparation method of complex body in the present embodiment is consistent with embodiment 2, difference only lies in step (3), specifically as follows:

[0073] (3) get the green rust 50mg that step (2) obtains, add 10mmol / L sodium hydrogen phosphate aqueous solution 100mL, the final concentration of green rust is 0.5g / L, the iron element in the green rust and the phosphorus element in the sodium hydrogen phosphate The molar ratio is 0.4:1. After fully stirring, a patina-phosphate complex suspension with a Fe / P molar ratio of 0.4:1 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com