Rice storage and dust removal integrated system

A dust removal system and technology for rice, applied in the field of rice storage, can solve the problems of serious dust pollution, reduced rice quality, low economic value of rice, etc., and achieve the effect of improving working environment and good cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

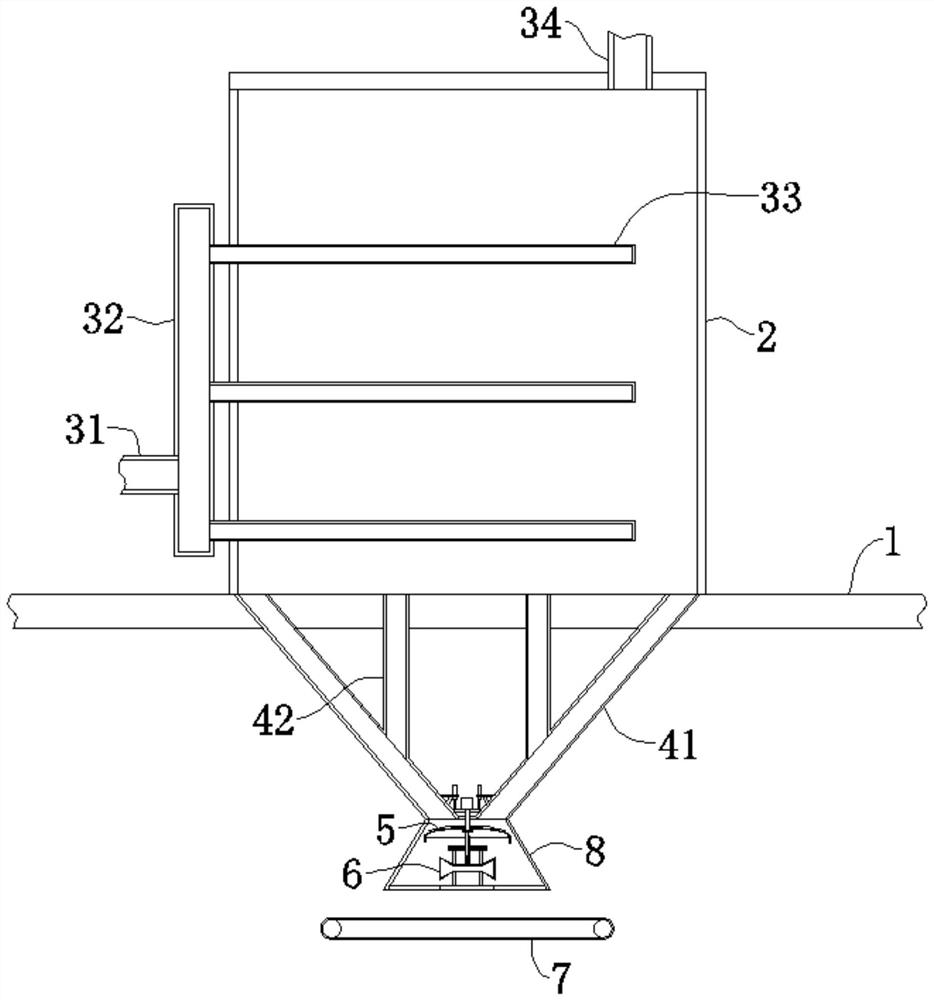

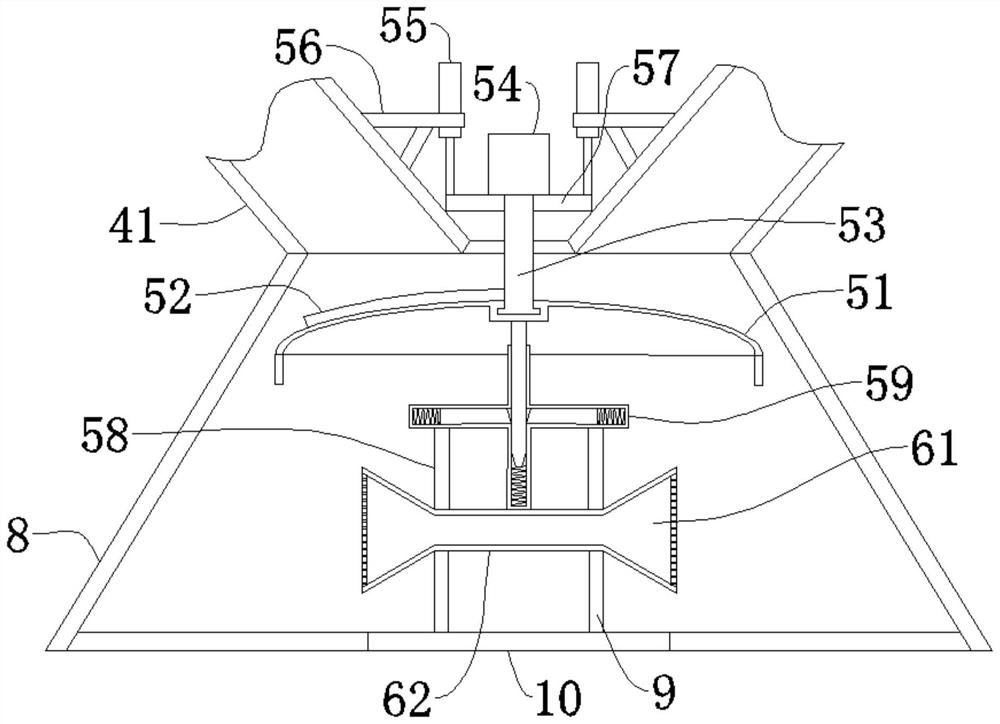

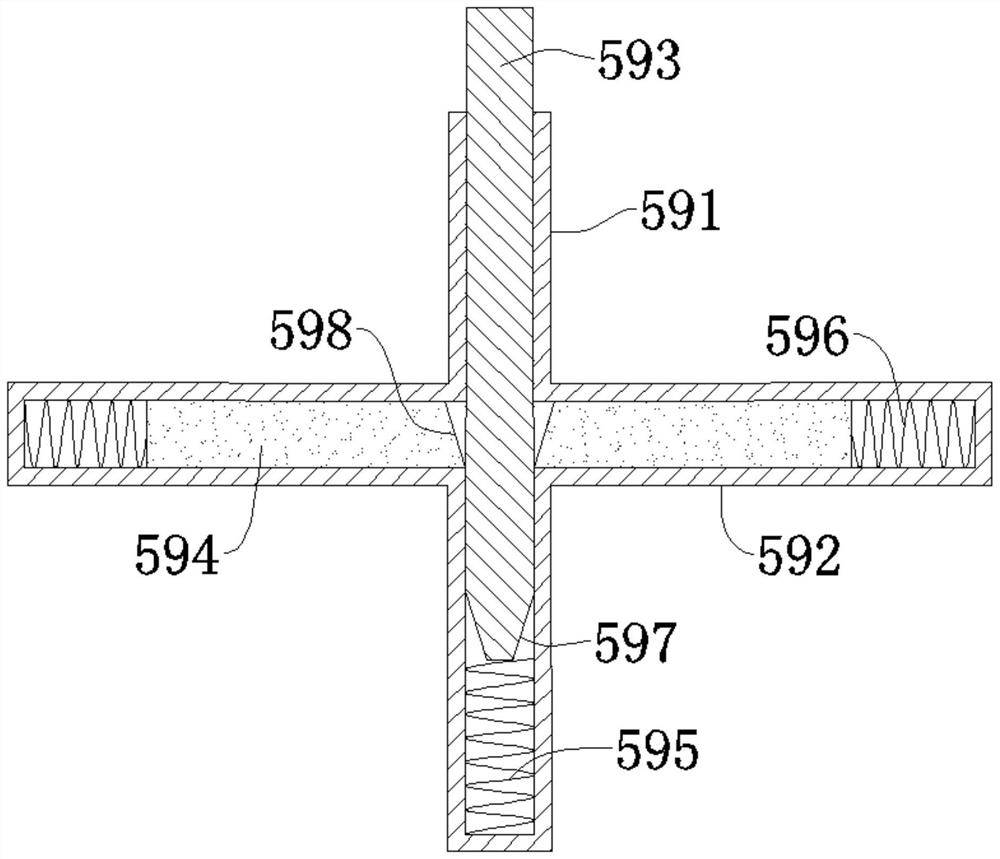

[0044] Embodiment: a kind of paddy storage dust removal integrated system, such as Figure 1-5 As shown, it includes a storage bin 2, a support platform 1, a cold air supply system, a feeding channel, a discharging cover 8, a feeding control device 5, a dust removal system 6 and a belt conveyor 7. The storage bin 2 is used to store rice, and the storage bin 2 is placed on the support platform 1, and the height of the support platform 1 is higher than the foundation ground, so that the storage bin 2 is raised by the support platform 1, so that the storage bin 2 is positioned above the ground to prevent storage Warehouse 2 is damp. The unloading channel is located below the support platform 1, the upper end of the unloading channel passes through the support platform 1 and is connected with the bottom of the storage bin 2, and the lower end is connected with the top of the discharge cover 8. The feeding channel includes an inclined channel 41 and a vertical channel 42. The uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com