Plate splicing automatic production line

An automatic production line, rectangular technology, applied in the direction of liquid injection devices, spray booths, forming/shaping machines, etc., can solve the problems of time-consuming and labor-intensive, affecting production efficiency, etc., to improve drying efficiency, improve work efficiency, and prevent wood chips from flying randomly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

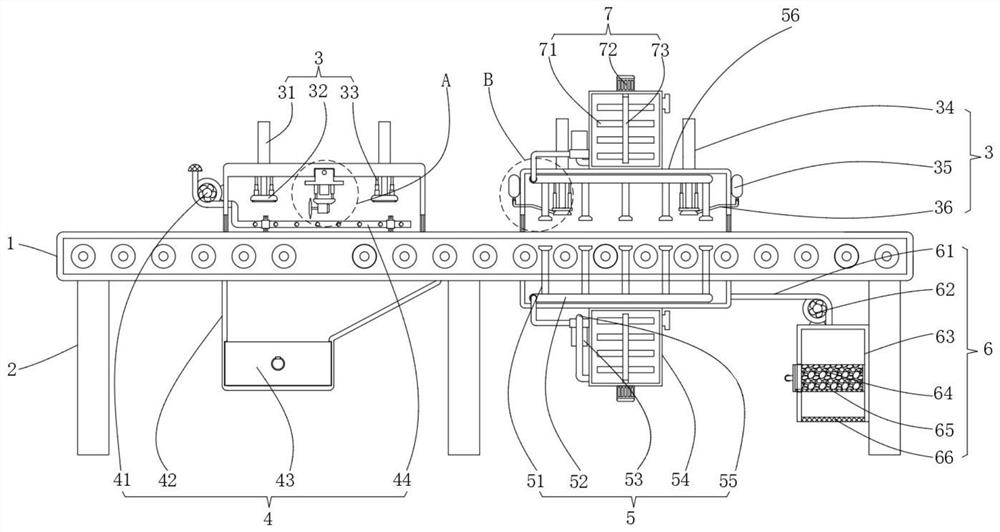

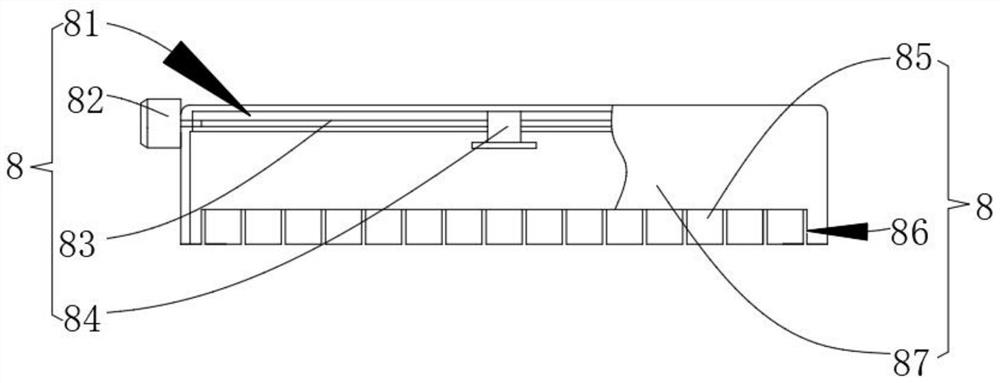

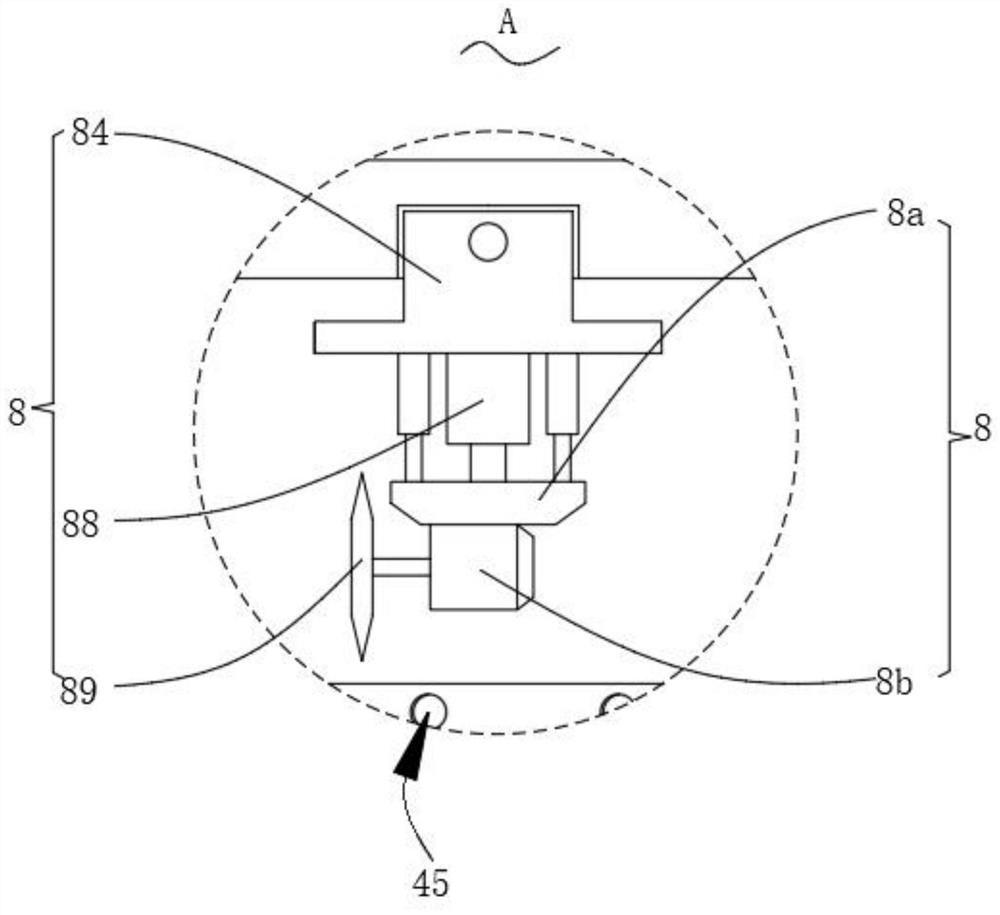

[0028] Please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 ,in, figure 1 A structural schematic diagram of a preferred embodiment of the board splicing automatic production line provided by the present invention; figure 2 for figure 1 The partial structural schematic diagram of the side view direction of the second rectangular cover shown; image 3 for figure 1 The schematic diagram of the partially enlarged structure shown at A; Figure 4 for figure 1 The schematic diagram of the partially enlarged structure shown at B; Figure 5 for figure 1 The schematic diagram of the structure of the long box shown in the top view direction. The board splicing automatic production line includes: long box 1, pressing and fixing structure 3, waste cleaning and collecting structure 4, spraying structure 5, odor treatment structure 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com