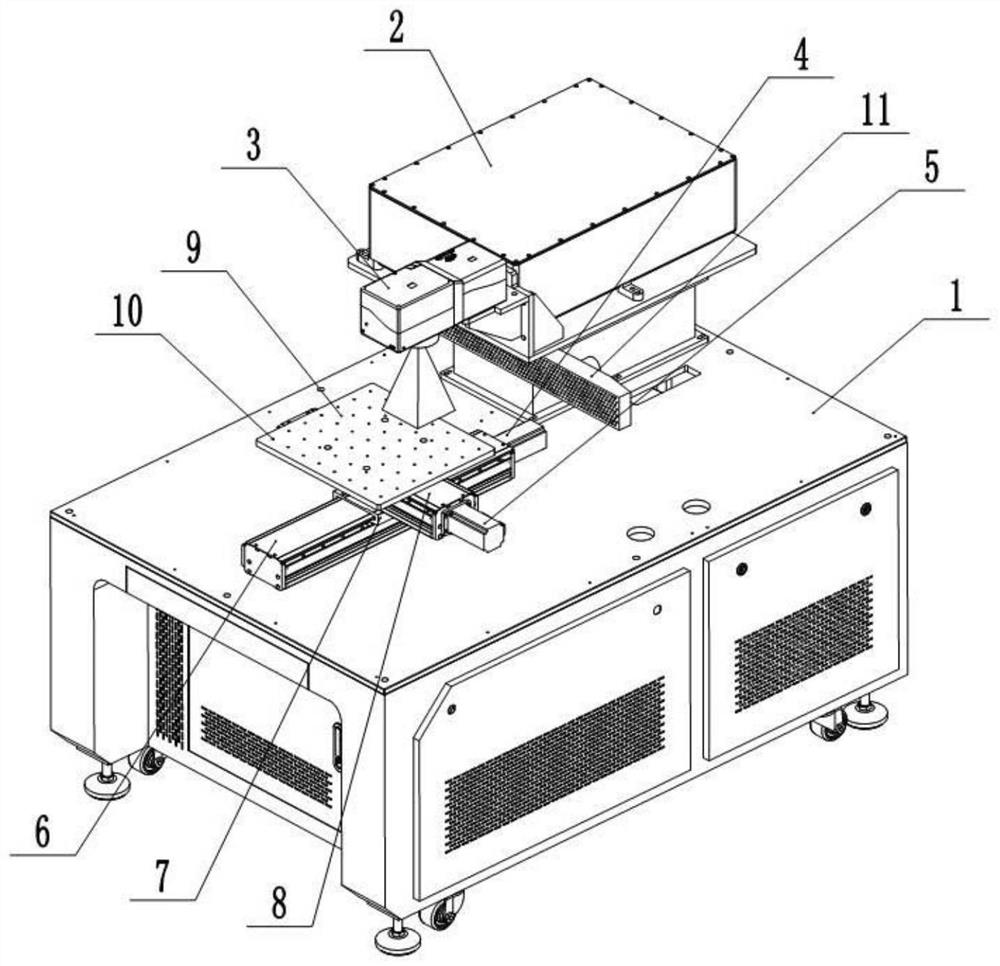

Laser engraving process of magnesium-aluminum panel for notebook computer

A notebook computer, magnesium-aluminum technology, used in manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problem of large damage to the metal bottom plate, and achieve the effect of low weight, high efficiency, and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The laser engraving process of magnesium aluminum panels for notebook computers includes the following steps:

[0028] The magnesium-aluminum parts formed by CNC form a primer on the surface of the magnesium-aluminum part. The thickness of the primer is 20-25um. After the primer is dried, laser engraving is performed on it with a laser engraving machine. Choose a laser transmitter with an output power of not less than 50W, and set the output power to 100% of the average output power, 20HZ frequency, 0.03-0.05mm spacing between filling lines, 3000mm / s scanning speed, and 19.89mm carving depth. um.

[0029] After the carving is completed, a topcoat is formed on the surface of the carving, and the thickness of the topcoat is 10-15um.

[0030] Carry out conventional and salt spray tests on the magnesium-aluminum parts after the above-mentioned engraving process. The environment of the salt spray test is a salt solution with a concentration of 5%. The test results are shown...

Embodiment 2

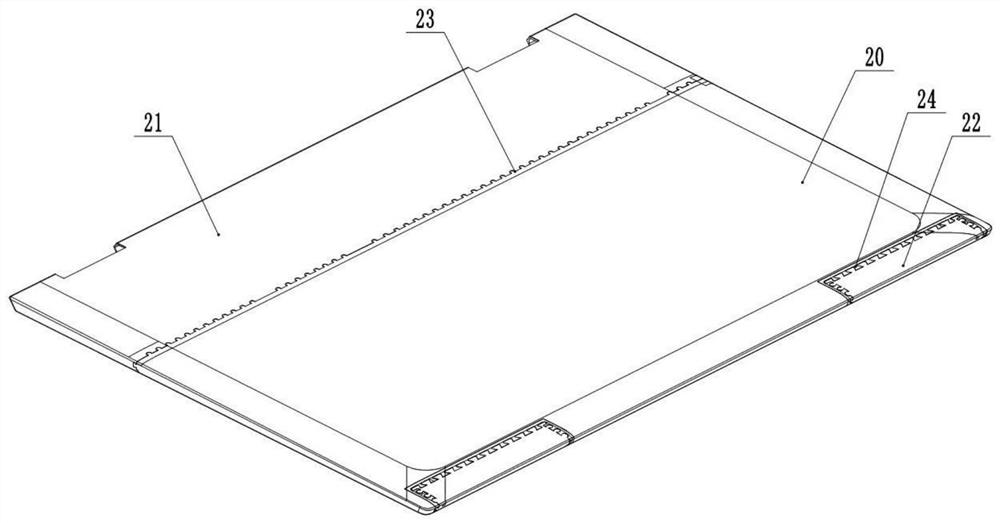

[0039] Basic as attached figure 2 Shown: The difference from Embodiment 1 is that the magnesium-aluminum plate 21 includes a panel body, wherein the panel body includes a magnesium plate 20 and an aluminum plate 21 connected to each other, the area of the magnesium plate 20 is much larger than that of the aluminum plate 21, and the magnesium plate 20 is far away from the aluminum plate 21 Two connection notches are arranged symmetrically on one side, and the connection notches are set close to the side of the magnesium plate 20 , and a plastic plate 22 is arranged in the connection notches.

[0040] The specific connection method between the magnesium plate 20 and the aluminum plate 21 is that a number of irregular first grooves 23 are arranged on the side of the aluminum plate 21 close to the magnesium plate 20, and the number of first grooves 23 are distributed along the side spacing of the aluminum plate 21. , while a number of irregular first protrusions are correspondi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com