Sintering flue gas treatment method

A technology for sintering flue gas and treatment method, which is applied in the directions of gas treatment, separation method, chemical instrument and method, etc., can solve the problems of not having good desulfurization effect at the same time, and easy treatment of desulfurization products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

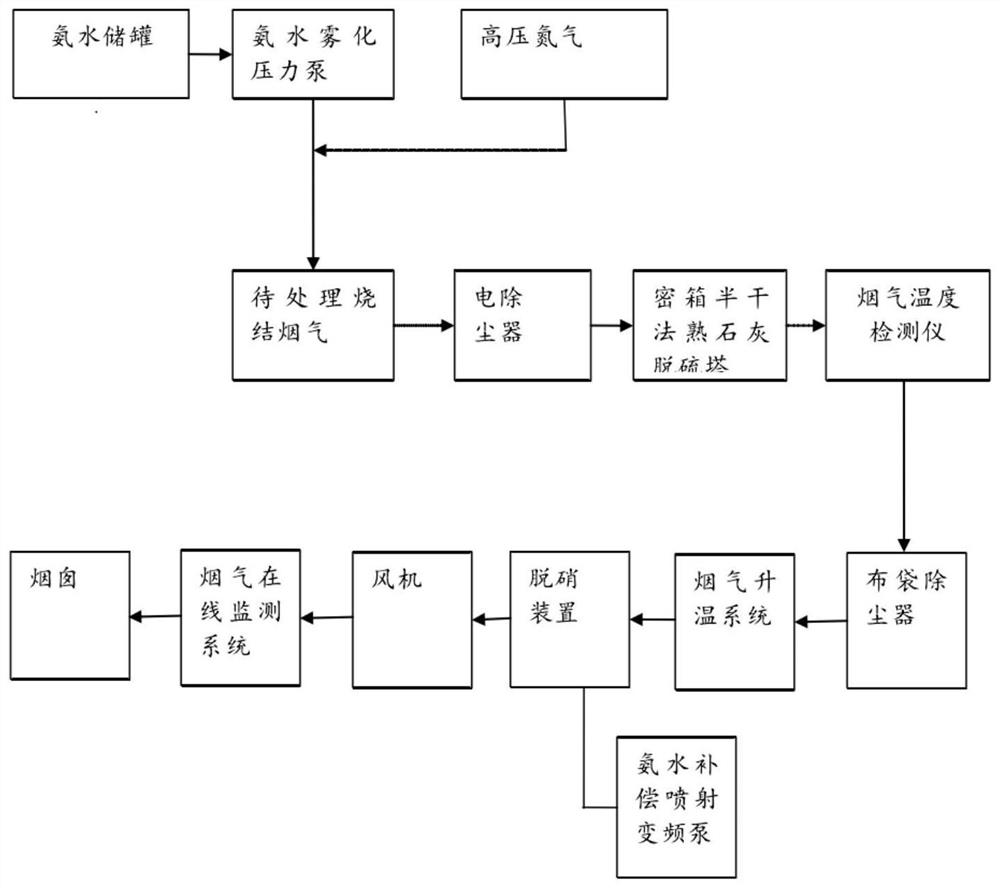

[0054] The preparation device for atomized ammonia water includes an ammonia water storage tank, an ammonia water atomization pressure pump and a two-phase nozzle, the inlet of the ammonia water atomization pressure pump is connected to the ammonia water storage tank; the two-phase nozzle includes a first phase inlet and a second phase inlet connected to each other and the outlet, the first phase inlet in the two-phase nozzle is connected with the outlet of the ammonia water atomization pressure pump, the second phase inlet in the two-phase nozzle is connected with the external high-pressure nitrogen, and the atomized ammonia water ejected from the outlet of the two-phase nozzle is The ammonia water atomization pressure pump is used to carry out pressure atomization of ammonia water and high-pressure nitrogen atomization to obtain it. This method has excellent atomization effect, small droplets and high rate. The equipment for processing the sintering flue gas to be treated is ...

Embodiment 1

[0060] The sintering flue gas to be treated undergoes a desulfurization reaction with the atomized ammonia water with a mass concentration of 8% in the flue to perform first-stage desulfurization, wherein the droplet diameter of the atomized ammonia water is ≤150 μm, and the movement direction of the sintered gas to be treated and the atomized ammonia water is the same. The atomized ammonia water is obtained through the joint action of ammonia water pressure atomization and high-pressure nitrogen atomization, wherein the pressure of ammonia water is 0.5MPa, and the pressure of high-pressure nitrogen gas is 0.5MPa. The sintering flue gas to be treated after the primary desulfurization enters the electrostatic precipitator for dust removal to obtain the primary desulfurization sintering flue gas. The length of the flue between the atomized ammonia water preparation device and the electrostatic precipitator is 50m. The temperature of the first-stage desulfurization sintering flue ...

Embodiment 2

[0062] The sintering flue gas to be treated undergoes a desulfurization reaction with the atomized ammonia water with a mass concentration of 18% in the flue to perform first-level desulfurization, wherein the atomized ammonia water droplet diameter is ≤ 130 μm, and the movement direction of the sintered gas to be treated is the same as that of the atomized ammonia water. The atomized ammonia water is obtained through the joint action of ammonia water pressure atomization and high-pressure nitrogen atomization, wherein the pressure of ammonia water is 0.6MPa, and the pressure of high-pressure nitrogen gas is 0.7MPa. The sintering flue gas to be treated after the primary desulfurization enters the electrostatic precipitator for dust removal to obtain the primary desulfurization sintering flue gas. The length of the flue between the atomized ammonia water preparation device and the electrostatic precipitator is 80m. The temperature of the first-stage desulfurization sintering flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com