A kind of supercritical carbon dioxide thickener and its preparation method and application

A carbon dioxide and supercritical technology, applied in the field of oil field fracturing, can solve the problems of unfavorable storage, transportation and environmental protection, high consumption and high cost, and achieve the effect of eliminating post-treatment process, realizing oil layer production increase, and optimizing synthesis reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] According to the second aspect of the present invention, the present invention provides a kind of preparation method of supercritical carbon dioxide thickener, the method comprises the steps:

[0037] In a supercritical carbon dioxide medium, each component is reacted under stirring conditions, and the reaction conditions include: temperature of 30-100° C., pressure of 7-30 MPa, and time of 8-16 hours.

[0038] Preferably, the reaction conditions include: a temperature of 50-60° C., a pressure of 7-10 MPa, and a time of 10-12 hours.

[0039] Preferably, the components are added to the reaction in a sealable reactor, such as a reactor.

[0040] Fill the reactor with CO 2 Gas, such as filling with a pump, if the required pressure is not reached, add CO 2 gas.

[0041] Preferably, the progress of the reaction is monitored through pressure changes, and after the final system pressure no longer changes, the temperature of the reactor is lowered to room temperature, for ex...

Embodiment 1

[0047] 100 parts by weight of polydimethylsiloxane with a viscosity of 50 mPa·s, 50 parts by weight of n-butyl acrylate, 1 part by weight of styrene, 0.05 parts by weight of azobisisobutyronitrile and 3 parts by weight of dodecyl Put sodium benzenesulfonate into the reaction kettle, seal it, and inject CO with a pump 2 Gas, pressurized to 7MPa, then close the inlet and outlet valves, and heat. Raise the temperature to 50°C, start the stirrer, and react for 10 hours. After the reaction, it was naturally cooled to room temperature. Open the outlet valve and slowly reduce to normal pressure, the product is a porous white solid.

Embodiment 2

[0049]200 parts by weight of polydimethylsiloxane with a viscosity of 100 mPa·s, 50 parts by weight of 2-ethylhexyl acrylate, 2 parts by weight of sodium styrene sulfonate, 0.06 parts by weight of azobisisobutyronitrile and 1 The sodium dodecylbenzene sulfonate of weight part is put into reactor, seals, and pumps into CO 2 Gas, pressurized to 10MPa, then close the inlet and outlet valves tightly, and heat. Raise the temperature to 60°C, start the stirrer, and react for 12 hours. After the reaction, it was naturally cooled to room temperature. Open the outlet valve and slowly reduce to normal pressure, the product is a porous white solid.

PUM

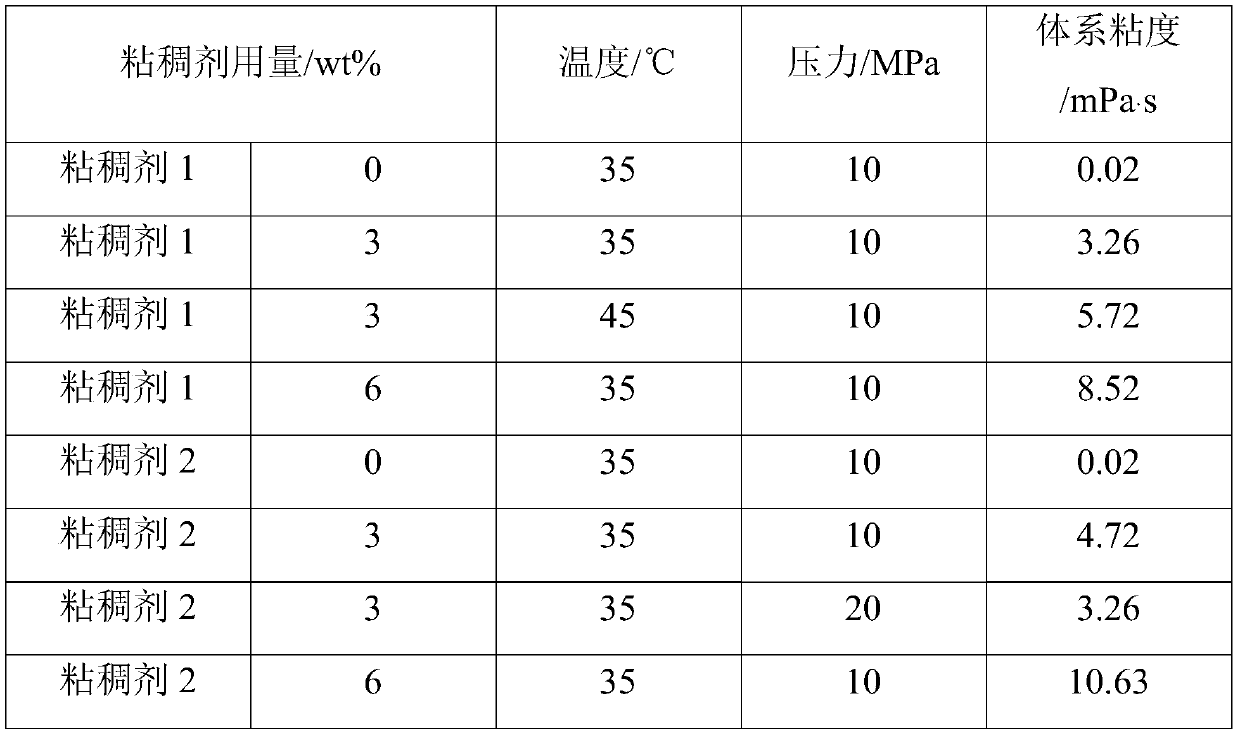

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com