Gradient extraction method for oil-stone separation of waste asphalt mixture

A waste asphalt and mixture technology, which is applied in the preparation of liquid hydrocarbon mixture, solid solvent extraction, petroleum industry, etc., can solve the problems of large demand for extractant, low concentration of asphalt, and no economic significance, so as to achieve green development, Reduce solvent loss and reduce the effect of low amount of mixed solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A gradient extraction method for separating waste and old asphalt mixture oil stones, comprising the steps of:

[0053] (1) Collect the waste asphalt mixture, and spray and clean the collected waste asphalt mixture with 3 times the standard atmospheric pressure high-pressure water mist for 2 hours, then drain the cleaned waste asphalt mixture and dry it at 90°C Dehydration, crushing and sieving the dried waste asphalt mixture to obtain the waste asphalt mixture particles after the fine powder is released;

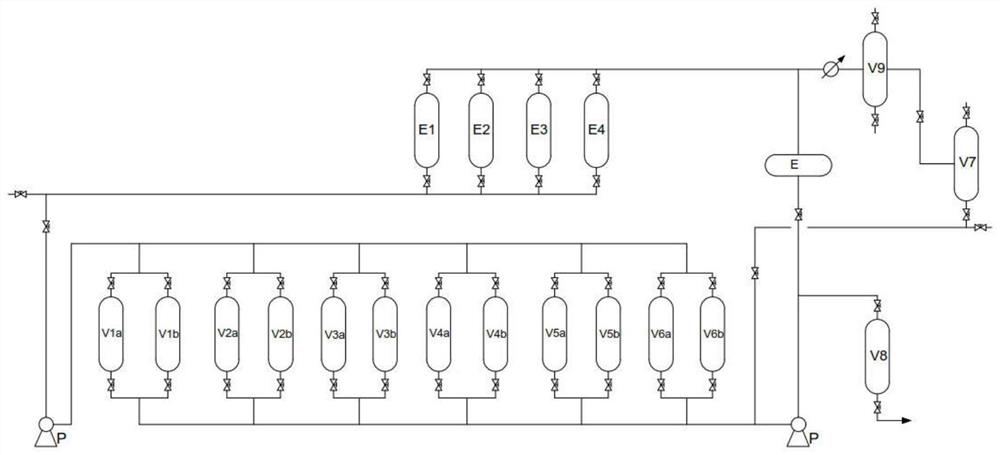

[0054] (2) Continuous gradient extraction of waste asphalt mixture particles through a composite solvent, the composite solvent includes the following components: 81.3% toluene, 9.2% turpentine, 3.6% tea seed oil and 5.9% No. 100 mineral spirits. Fill the dried waste asphalt mixture particles into the E with a volume of 600L 1 ,E 2 ,E 3 ,E 4 After the oilstone extraction tower, start the continuous gradient extraction, the steps are as follows:

[0055] 2.1) For...

Embodiment 2

[0071] A gradient extraction method for separating waste and old asphalt mixture oil stones, comprising the steps of:

[0072] (1) Collect the waste asphalt mixture, and spray and clean the collected waste asphalt mixture with high-pressure water mist at twice the standard atmospheric pressure for 3 hours, then drain the cleaned waste asphalt mixture and dry it at 80°C Dehydration, crushing and sieving the dried waste asphalt mixture to obtain the waste asphalt mixture particles after the fine powder is released;

[0073] (2) Continuous gradient extraction of waste asphalt mixture particles through a composite solvent, the composite solvent includes the following components: 67.8% toluene, 15.4% turpentine, 7.5% tea seed oil and 9.3% No. 100 mineral spirits. Fill the dried waste asphalt mixture particles into the E with a volume of 600L 1 ,E 2 ,E 3 ,E 4 After the oilstone extraction tower, start the continuous gradient extraction.

[0074] The difference from Example 1 is...

Embodiment 3

[0081] A gradient extraction method for separating waste and old asphalt mixture oil stones, comprising the steps of:

[0082] (1) Collect the waste asphalt mixture, and spray and wash the collected waste asphalt mixture with 4 times the standard atmospheric pressure high-pressure water mist for 1 hour, then drain the cleaned waste asphalt mixture and dry it at 95°C Dehydration, crushing and sieving the dried waste asphalt mixture to obtain the waste asphalt mixture particles after the fine powder is released;

[0083] (2) Continuous gradient extraction of waste asphalt mixture particles through a composite solvent, the composite solvent includes the following components: 73.1% toluene, 12.2% turpentine, 5.6% tea seed oil and 9.1% No. 100 mineral spirits. Fill the dried waste asphalt mixture particles into the E with a volume of 600L 1 ,E 2 ,E 3 ,E 4 After the oilstone extraction tower, start the continuous gradient extraction.

[0084] The difference from Example 1 is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com