Rapid crayfish pretreatment device

A pretreatment device and lobster technology, applied in the field of lobster farming, can solve the problems of loss of crayfish meat elasticity, poor taste in crayfish shops, pincer injuries of operators, etc., so as to improve market competitiveness, save cleaning time, and increase unit price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

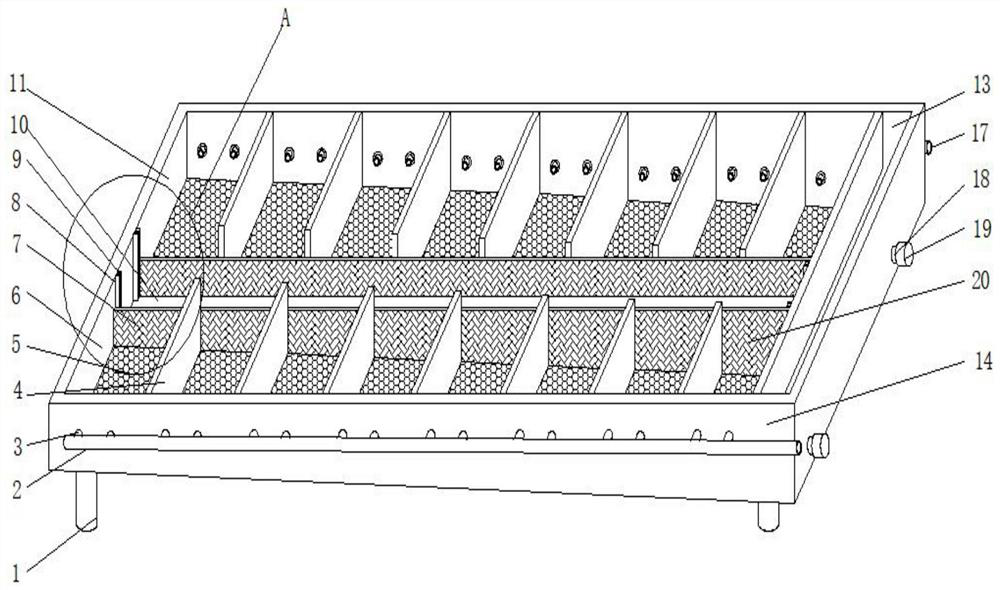

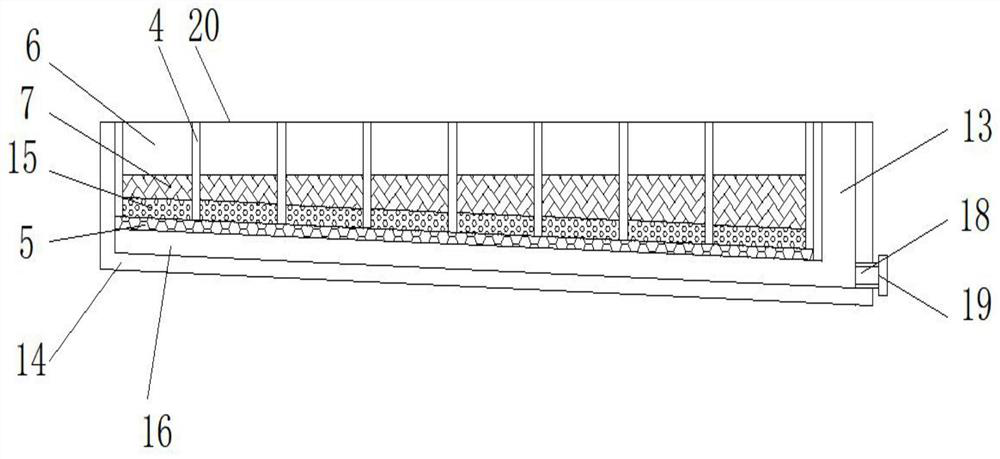

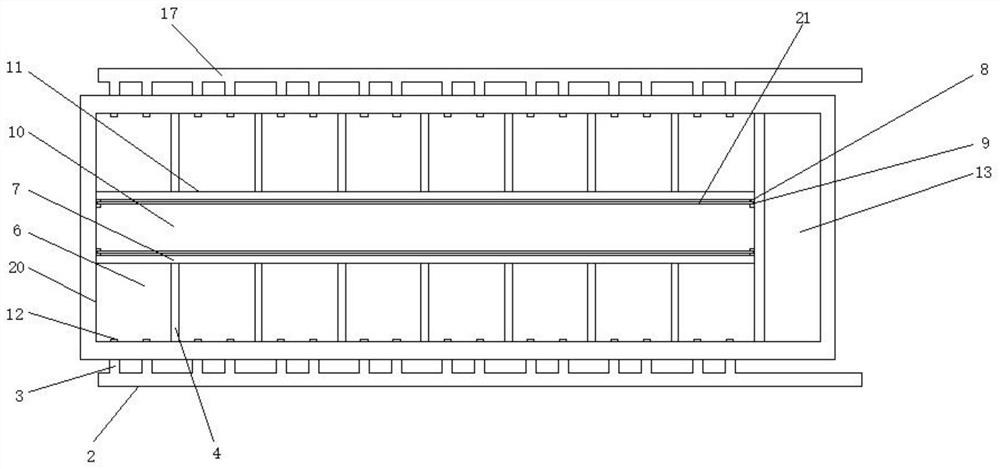

[0027] see Figure 1-5 , the present invention provides a technical solution: a rapid pretreatment device for crayfish, comprising a frame 14, a first water pipe 2 and a second water pipe 17, a first shrimp rack 20 is opened on the front side of the top of the frame 14, and the frame 14 is provided with a second shrimp rack 11 on the rear side of the top, and the first shrimp rack 20 is composed of a shrimp chamber 6, a filter plate 7, a partition plate 4 and a filter screen 5, and the bottom end of the shrimp chamber 6 is fixedly installed with a filter. Net 5, the front end of the shrimp chamber 6 is fixedly installed with a filter plate 7, the shrimp chamber 6 has several, and a partition plate 4 is fixedly welded at an equal distance between the shrimp chambers 6, and the bottom of the shrimp chamber 6 is filled There is a wood chip layer 15, a middle cavity 10 is formed between the first shrimp rack 20 and the second shrimp rack 11, and a cleaning groove 13 is reserved at...

Embodiment 2

[0029] see Figure 1-5 , the present invention provides a technical solution: a rapid pretreatment device for crayfish, comprising a frame 14, a first water pipe 2 and a second water pipe 17, a first shrimp rack 20 is opened on the front side of the top of the frame 14, and the frame 14 is provided with a second shrimp rack 11 on the rear side of the top, and the first shrimp rack 20 is composed of a shrimp chamber 6, a filter plate 7, a partition plate 4 and a filter screen 5, and the bottom end of the shrimp chamber 6 is fixedly installed with a filter. Net 5, the front end of the shrimp chamber 6 is fixedly installed with a filter plate 7, the shrimp chamber 6 has several, and a partition plate 4 is fixedly welded at an equal distance between the shrimp chambers 6, and the bottom of the shrimp chamber 6 is filled There is a wood chip layer 15, a middle cavity 10 is formed between the first shrimp rack 20 and the second shrimp rack 11, and a cleaning groove 13 is reserved at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com