Preparation method of vector compensation volume Bragg grating angle deflector

A technology of volume Bragg grating and vector compensation, which is applied in the direction of diffraction grating, instrument, optics, etc., can solve the problems of reduced diffraction efficiency of incident beam, mismatch of working wavelength, deviation of incident beam, etc., to improve diffraction efficiency, simple method, and angle good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

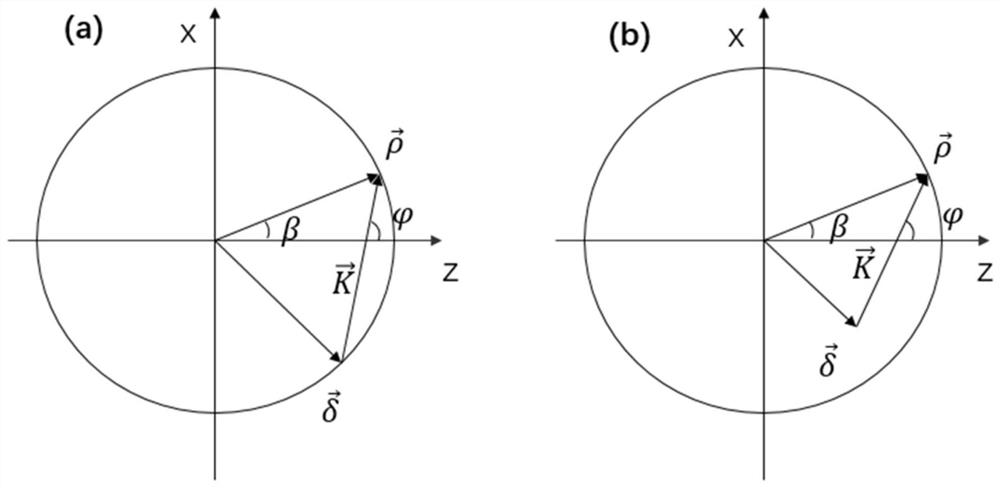

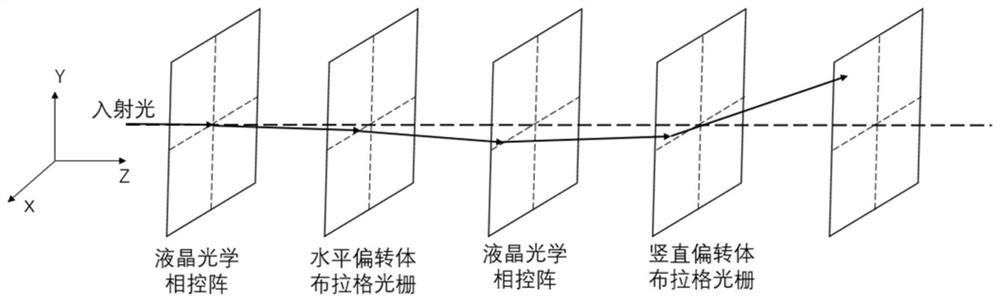

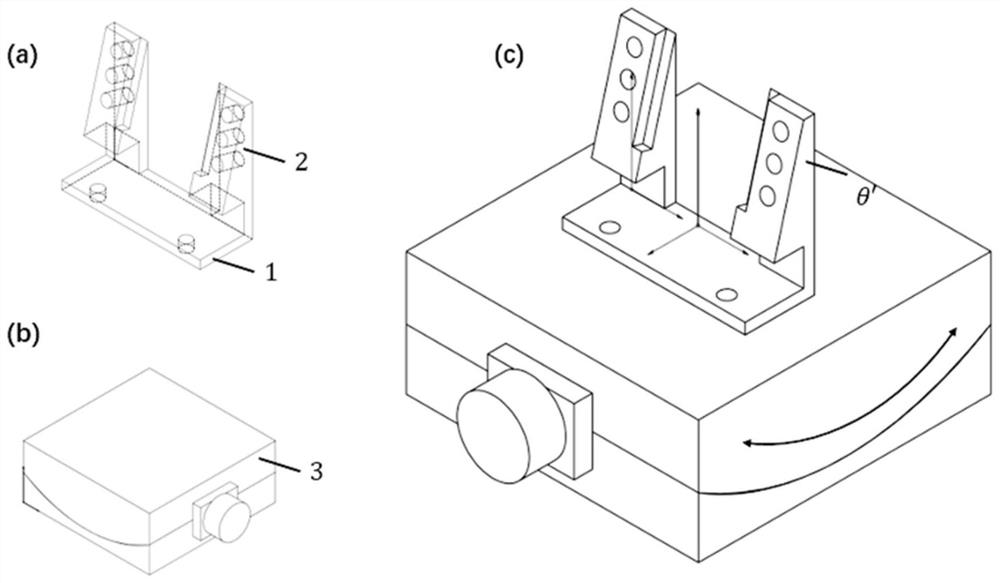

[0032] In this embodiment, photothermo-refractive (PTR) glass is used as the recording material, and the working wavelength is 1064nm. The angle θ' between the two splints of the designed sample holder splint group is 15°, and the combination with the one-dimensional arc swing table can realize- The angle adjustment range of 15°-45° meets the angle range of the conventional cone angle incident beam of 0°-45°. The cone angle θ of the cone angle incident beam implemented in this embodiment is 20°, so the angle α of the one-dimensional arc swing table is adjusted to 5°. According to the requirements, the incident angle of the grating channel is 0° and the exit angle is 30°. According to the kogelnik coupled wave theory, after determining the incident angle and outgoing angle of the grating channel, the period and tilt angle parameters of the grating channel are calculated. Table 1 gives the channel angle deflection characteristics, structural parameters and vector compensation a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com