Phase-change microbial capsule grouting method for seepage prevention of fractured rock mass

A technology for fractured rock mass and microorganisms, which is applied in the field of phase-change microbial capsule grouting, and can solve the problem that microbial technology cannot be used in high and cold areas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

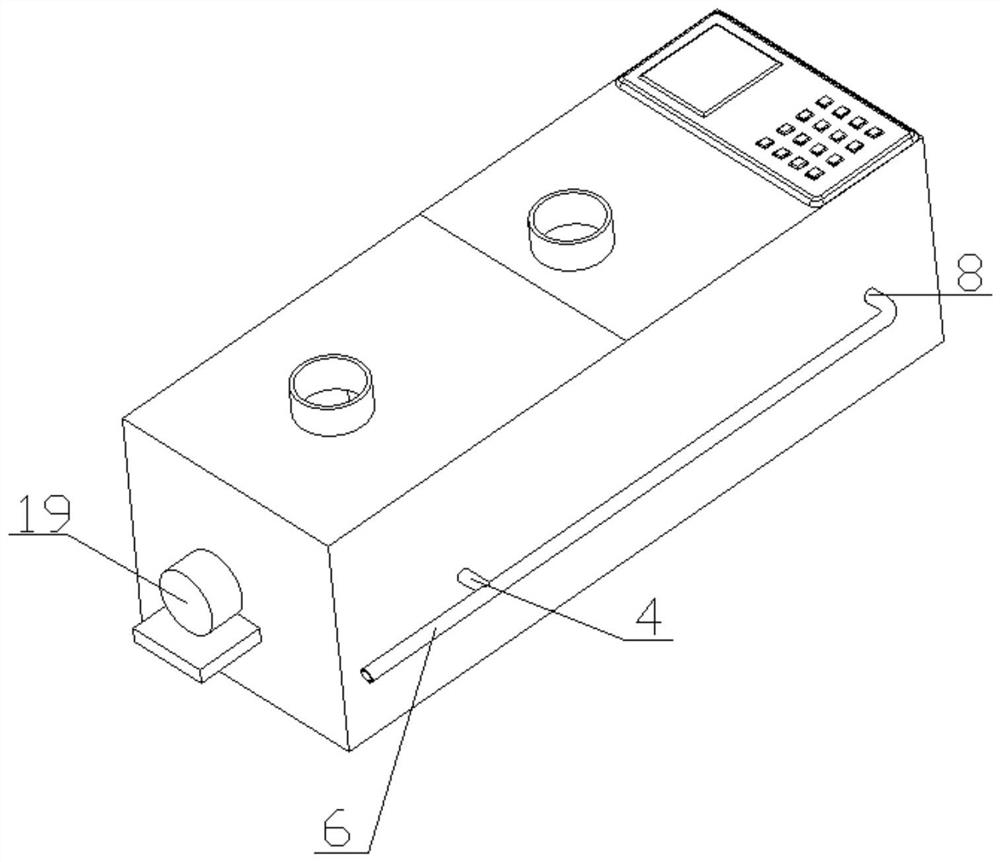

[0033] Such as Figure 1-7 Shown, a kind of phase-change microbial capsule grouting method that is used for anti-seepage of fracture rock mass comprises the following steps:

[0034] S 1 , Determine the position of the grouting hole on the rock mass fissure, and drill to form the grouting hole; S 2 , mixing the paraffin capsules and booster oil to obtain the first mixture; S 3 , mixing the microbial capsules with water to obtain a second mixture; S 4 1. Heating the first mixture so that the temperature of the first mixture is maintained at 35-40° C.; S 5 1. Continuously inject the second mixture into the fissures of the rock mass through the grouting device, and at the same time inject the first mixture intermittently into the fissures of the rock mass through the grouting device.

[0035] When using, first determine the position of the grouting hole on the rock mass, and the determination of the specific grouting hole position can refer to the empirical formula Among the...

Embodiment 2

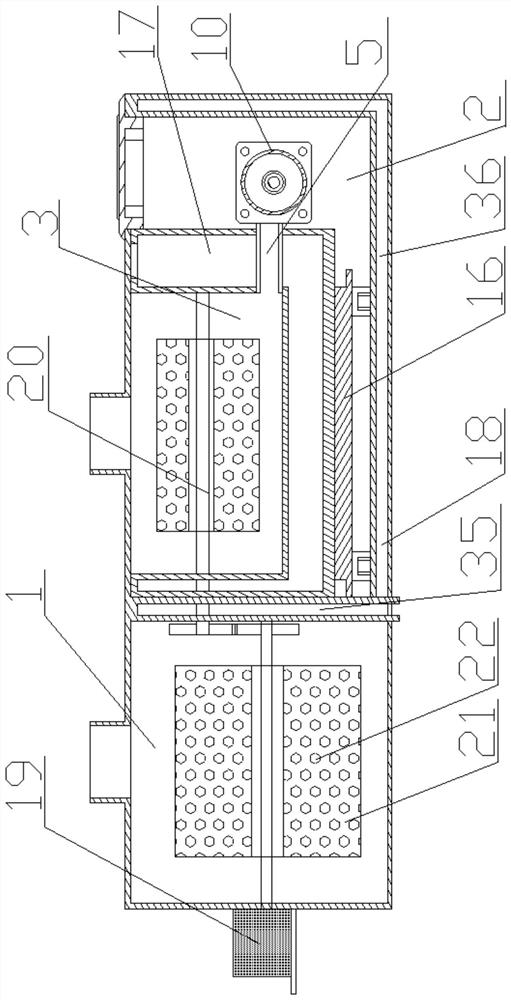

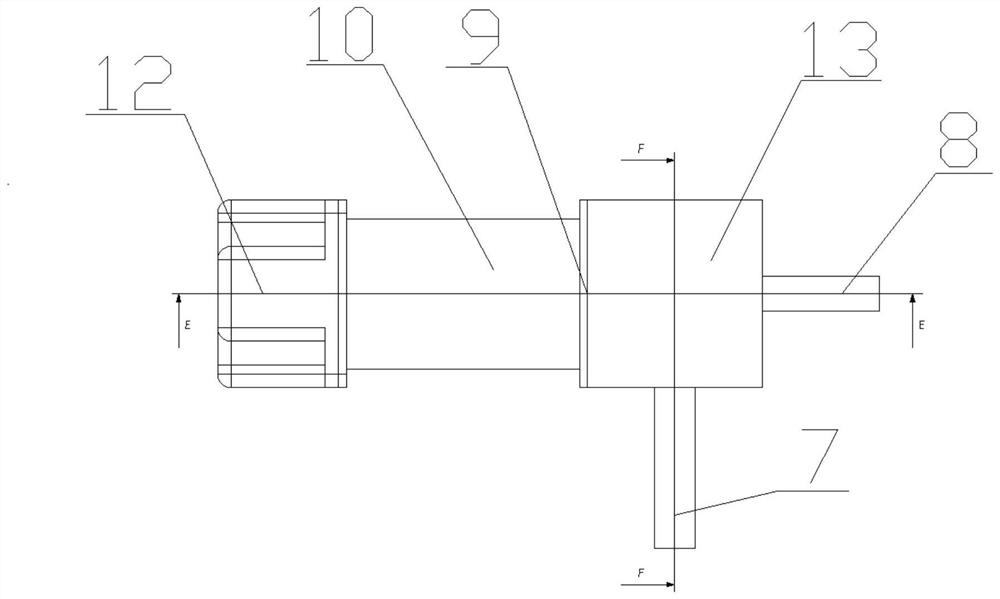

[0037] Such as Figure 1-7 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the grouting device includes a silo, and a partition is arranged in the silo, and the baffle divides the silo into the first liquid storage Box 1 and a second box body 2, the second box body 2 is provided with a heating device and a second liquid storage tank 3, the second mixture is added in the first liquid storage tank 1, and the first mixture is added In the second liquid storage tank 3, the first feed port and the first liquid outlet 4 communicated with the first liquid storage tank 1 are provided on the storage bin, and the second storage tank is provided with a The second feed port and the second liquid outlet 5 communicated with the liquid tank 3 are connected with the second liquid outlet 5 to be provided with an intermittent liquid supply device, and the intermittent liquid supply device can intermittently and quantitatively supply paraffin capsules and ...

Embodiment 3

[0040] Such as Figure 1-7 As shown, this embodiment is basically the same as Embodiment 2, the difference is that in the S 3 and S 4 Also includes step S between 35 , the step S 35 In order to use the stirring device to stir the water and the microbial capsule in the first liquid storage tank 1 to make it uniformly mixed, use the stirring device to stir the booster oil and the paraffin capsule in the second liquid storage tank 3 to make it uniformly mixed; wherein , the stirring device includes a driving motor 19, a central shaft 20, the central shaft 20 runs through the first liquid storage tank 1 and the second liquid storage tank 3, the driving motor 19 communicates with the central shaft 20, and is located in the first The central axes 20 of the liquid storage tank 1 and the second liquid storage tank 3 are provided with a plurality of stirring pieces 21 , and the stirring pieces 21 are provided with through holes 22 . Step S 5 When the first mixture starts grouting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com