Construction method of enclosing level rotary-jet pile hole-mouth using double-liquid slip jection method

A technology of horizontal rotary jetting piles and double-liquid grouting, which is used in sheet pile walls, soil protection, infrastructure engineering, etc. methods, and problems such as difficulty in transporting and driving wood piles into the equipment, to achieve the effects of simple and reliable construction methods, saving construction space and time, and improving construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

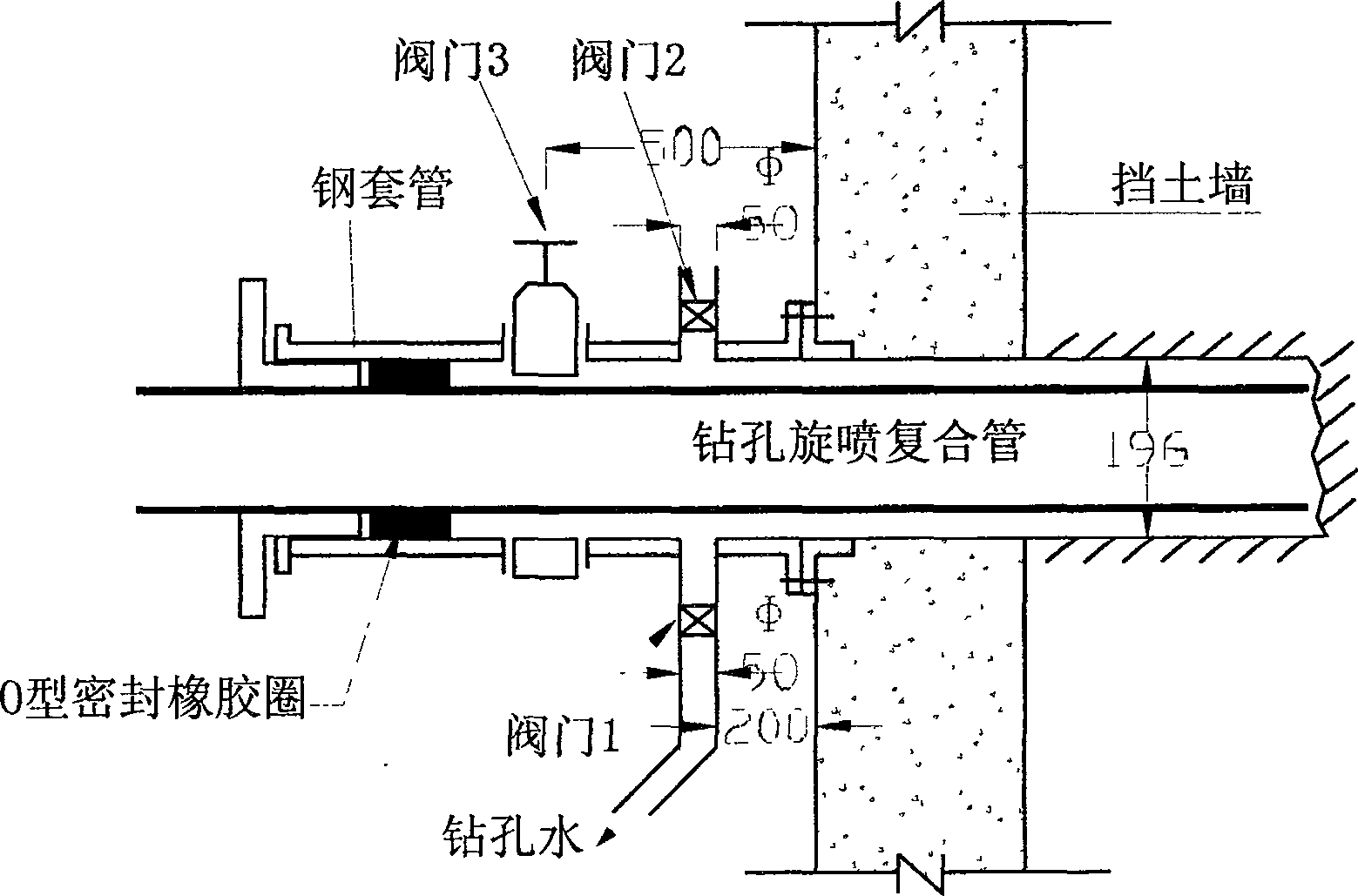

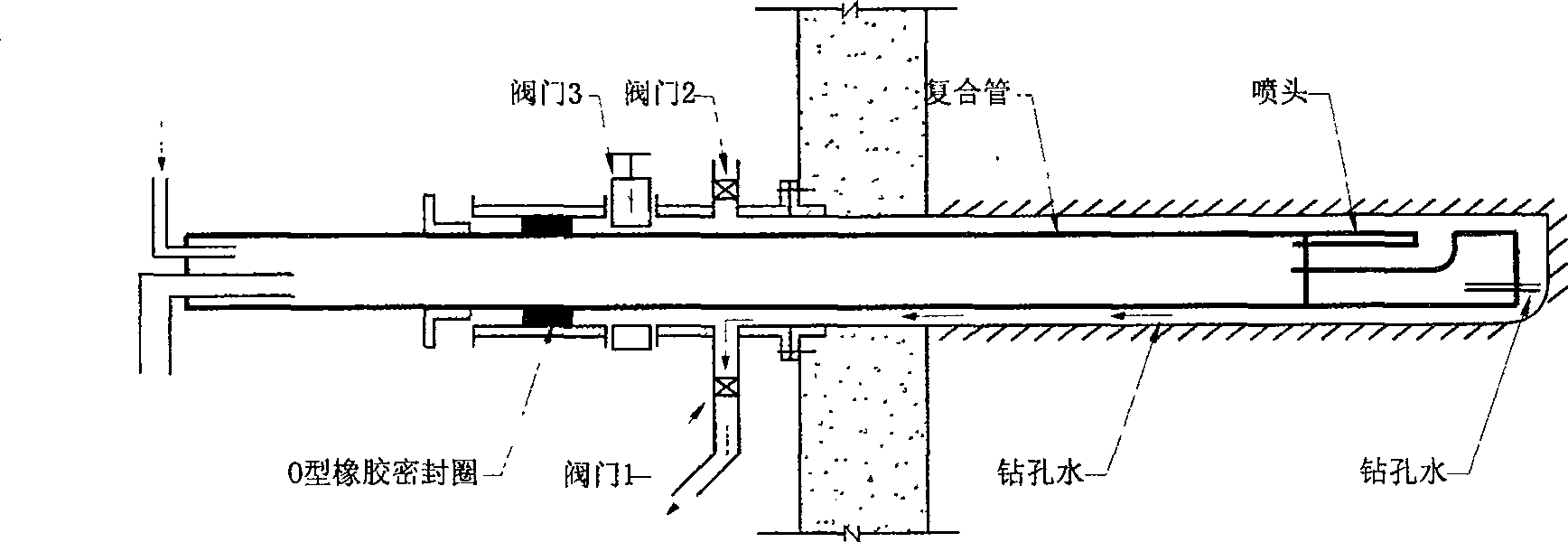

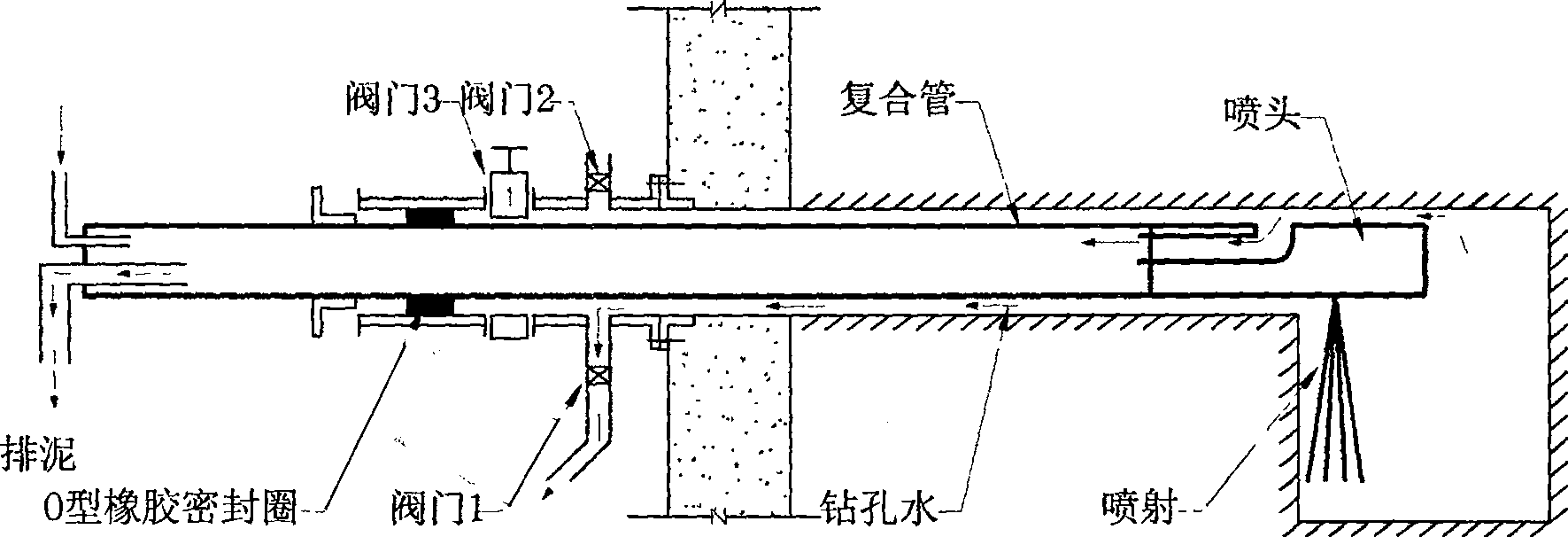

[0021] The test site is the reinforcement project of the exit end of a shield tunnel in a subway station in Shanghai. 5 horizontal jet grouting piles were constructed with the composite pipe horizontal jet grouting method, of which 3 piles were 9 meters long and 2 piles were 25.0 meters long; the single pipe method was used to construct 3 horizontal jet grouting reinforcements with a length of 9 meters. The pile diameter is 1.0-1.5 meters. The stratum reinforced on site is a silty clay layer④, which is in flow-plastic state. The water-cement ratio of cement slurry is 1:0.5. The sealing process of the rotary jet orifice is as attached figure 1 4. The details are as follows:

[0022] 1) The structure of the sealing tube is as attached figure 1 As shown, steel casings with water stop valve groups are installed on the outside of the retaining wall. The inner diameter of the steel pipe sleeve is 196mm, and it is connected to the underground retaining wall through a flange.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com