Method for in-situ production of solvent in oil layer to exploit thickened oil

An oil layer, in-situ technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of uneconomical, high operation cost of solvent injection and heavy oil production, and high solvent cost, and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

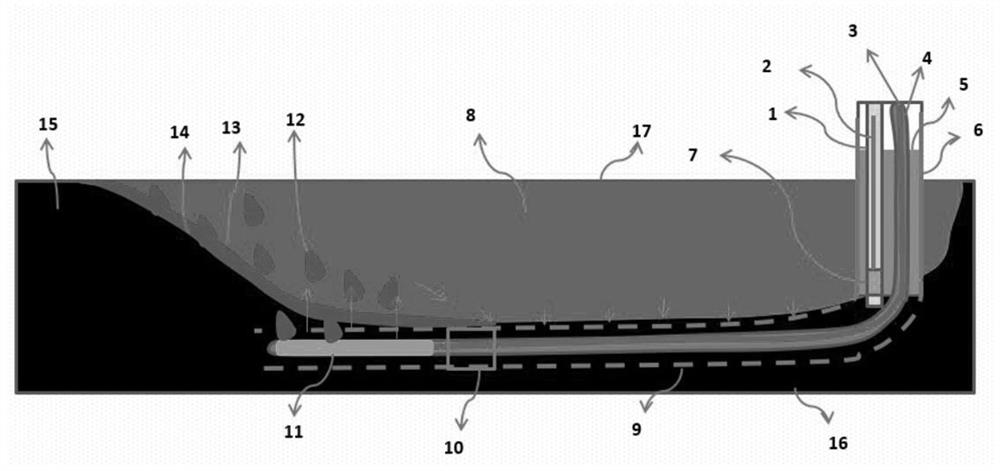

[0057] Example 1 (eg Figure 4 , Figure 5 shown)

[0058] A super-heavy oil reservoir adopts the SAGD production mode of vertical well gas injection and horizontal well production. The horizontal section of the horizontal well is 400 meters long and the operating pressure of the steam chamber is 4.0 MPa. After several years of continuous production with steam injection, a large volume of steam cavity has been formed in the reservoir, and the recovery degree of crude oil exceeds 45%. As SAGD enters the mid-to-late production stage, the heat loss ratio of steam injected into the steam cavity increases, the oil-steam ratio decreases, and the oil drainage rate decreases. In order to make full use of the waste heat in the steam chamber and reduce the steam consumption per unit oil production, it was decided to significantly reduce or stop steam injection on the ground. Laboratory studies and numerical simulation studies have shown that solvent-assisted SAGD is the best way to i...

Embodiment 2

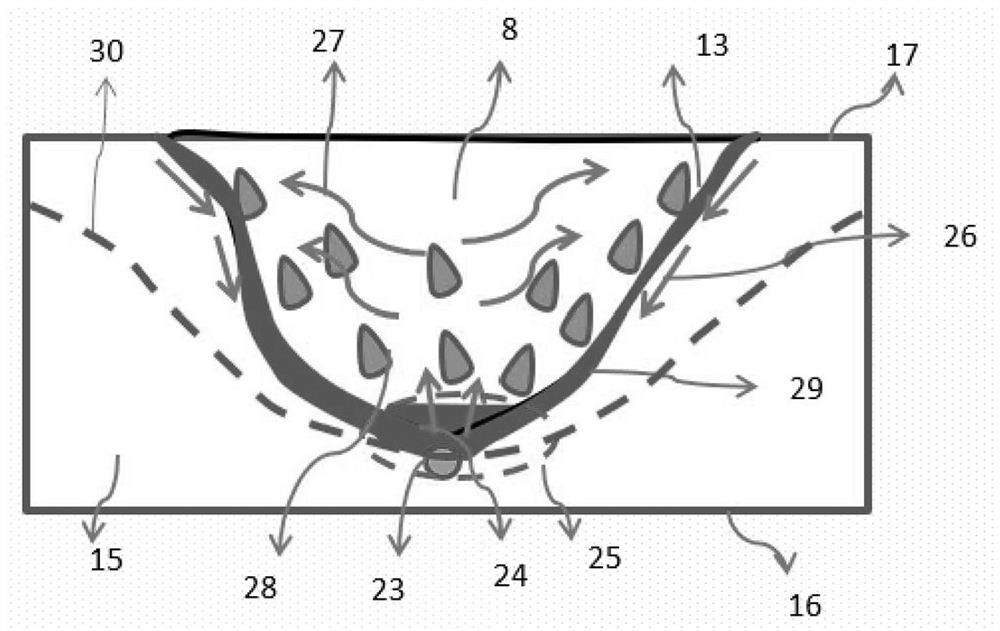

[0060] Example 2 (eg Figure 6 shown)

[0061] The viscosity of the crude oil in the reservoir is 5000-10000mPa.s at the reservoir temperature, the thickness of the pure oil layer is 5-10 meters, the depth of the oil layer is 2000 meters, and the pressure of the oil layer is 20 MPa. The crude oil in this reservoir has a certain flow ability at the reservoir temperature, but the cold recovery yield is low. Due to the limitation of oil layer depth and thickness, the thermal recovery efficiency of surface steam injection is low, and it is difficult to obtain an economical oil-gas ratio.

[0062] Drill a horizontal well with a horizontal section length of 400-600 meters in the oil layer, which is located at the bottom of the oil layer, and the horizontal section is completed with a screen (such as Figure 6 shown). All the downhole tubing strings and electrical heaters (200-300 kW), power cables and downhole temperature monitoring required for in situ generation of solvent reco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com