Elevator entrance threshold stone structure capable of preventing impact damage and convenient to construct and maintain

A technology of impact damage and threshold stone, which is applied in the field of architectural decoration and decoration, can solve the problems of inconvenient maintenance and operation of threshold stone, increased fragmentation of threshold stone, insufficient mortar filling at the bottom of threshold stone, etc., so as to reduce the probability of cracking in the hollow area and reduce the Probability of being damaged by impact, eliminating the effect of threshold stone being broken by impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

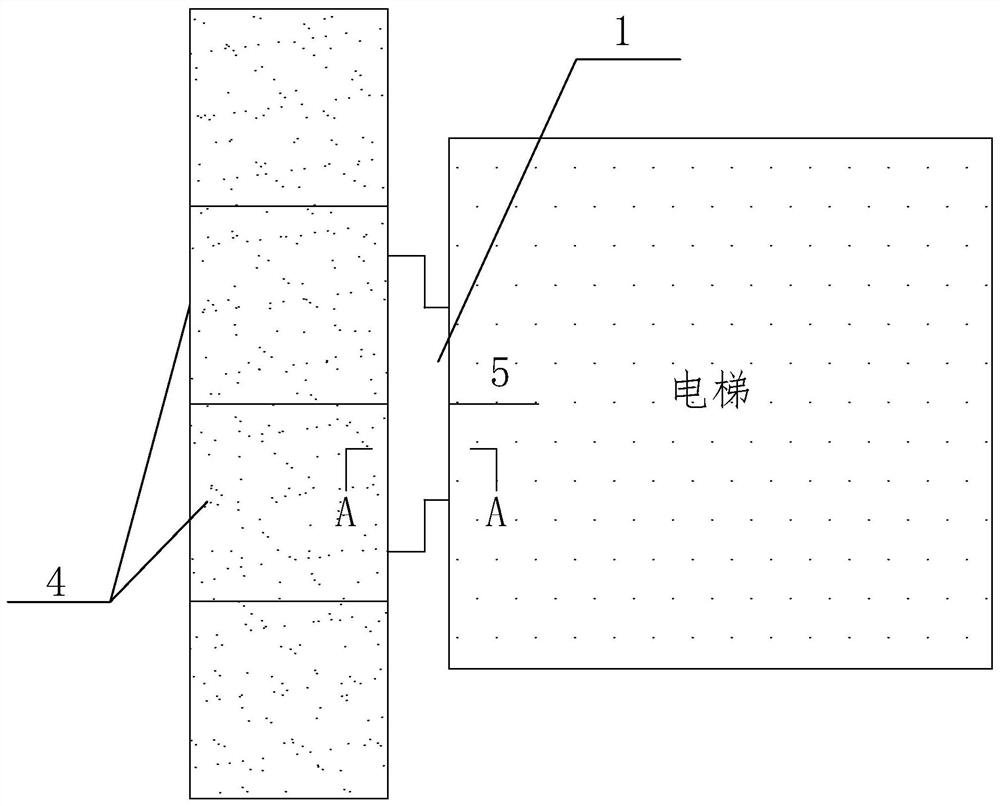

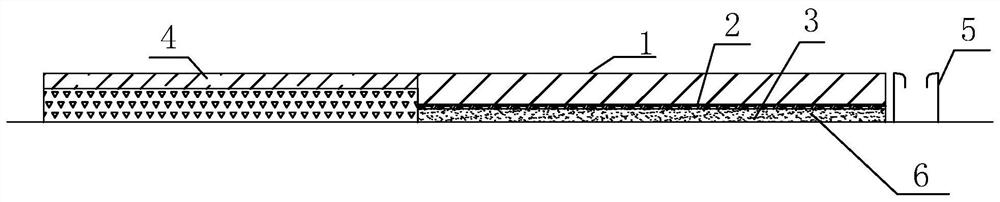

[0023] like Figure 1-Figure 2 As shown, a kind of anti-impact damage provided by the present invention and convenient for construction and maintenance of the threshold stone structure of the elevator entrance includes the main leveling layer 6 of the building ground, the elevator door sill 5, the floor tile paving area 4 in the building and the threshold stone 1. The threshold stone 1 is laid on the main leveling layer 6 of the building ground between the floor tile paving area 4 and the elevator door sill 5 in the building. A non-rigid support structure is set between the main leveling layer 6 of the building ground and the threshold stone 1, which plays the role of non-rigid support and replaces the traditional threshold stone paving cement mortar bonding layer, that is, the threshold stone rigid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com