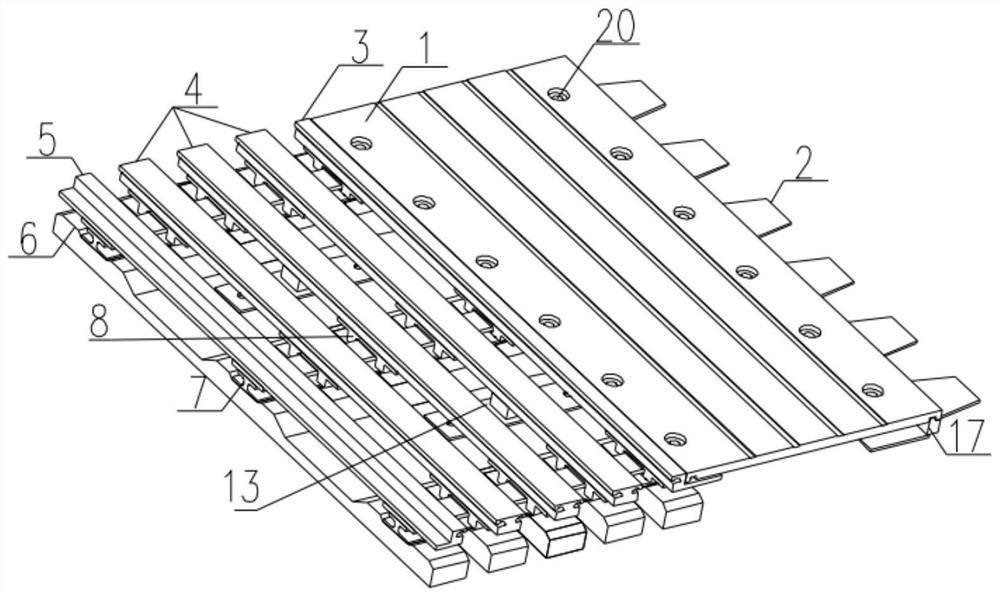

A fully assembled modular expansion joint

An expansion joint, modular technology, applied in the erection/assembly of bridges, buildings, bridge construction, etc., can solve the problems of large pouring volume, limited working space, prolonged construction cycle time, etc. And the effect of solid foundation and reduction of installation defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

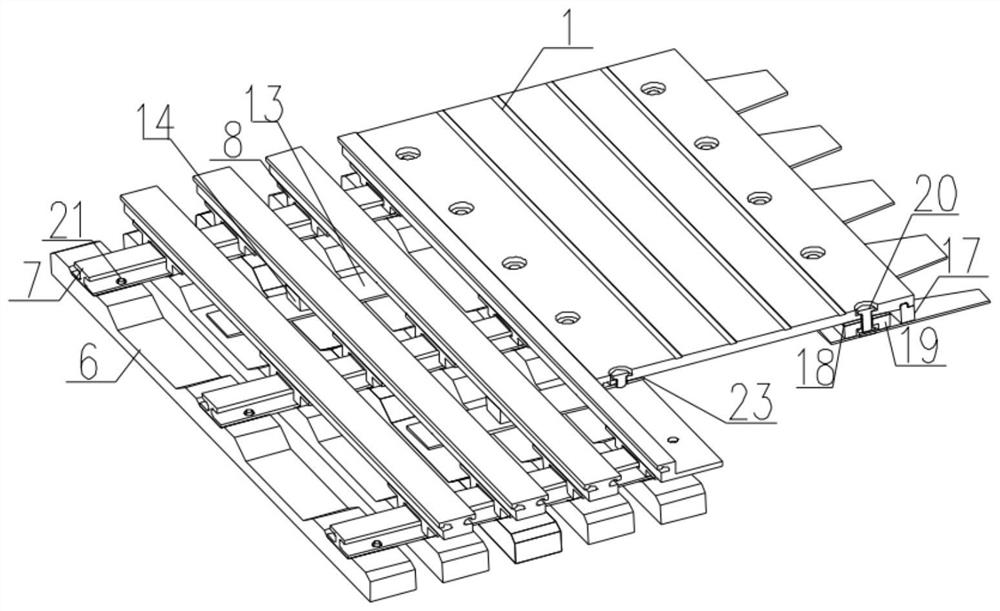

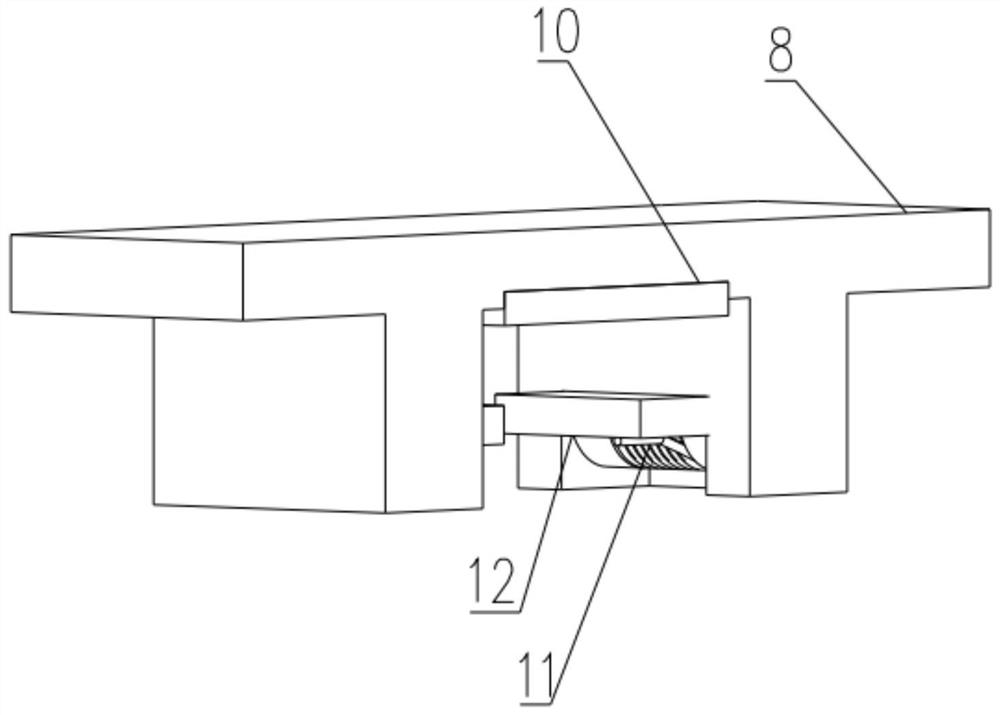

[0038] Embodiment 1, as shown in the figure, spanning board 1, fixed bottom plate 2, movable side beam 3, movable middle beam 4, fixed side beam 5, prefabricated sleeper 6, rail 7, slider 8, wear-resistant slide plate 10, torsion spring 11 , Movable slide plate 12, connecting plate 13, fixed connecting block 14, rubber spring 15, inserting rod 16, baffle plate 17, first elastic rubber bearing 18, bearing block 19, anti-loosening bolt 20, bolt 21, second Elastic rubber bearing 22, leveling bolt 23.

[0039] Fully-assembled modular bridge expansion device, including expansion components, spanning components, displacement control components, sliders and support components, the expansion components are limited to the support components set on the beam body, and one end of the spanning plate passes through the anti-loosening bolts It is fixed on the elastic support of the bottom plate at the fixed end, and the other end is fixed on the elastic support of the movable side beam throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com