Electroplating device

An electroplating device and electroplating box technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of forming impurities and affecting the quality of electroplating processing, etc., and achieve the effects of sufficient electromagnetic conversion, prolonging the vibration time, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

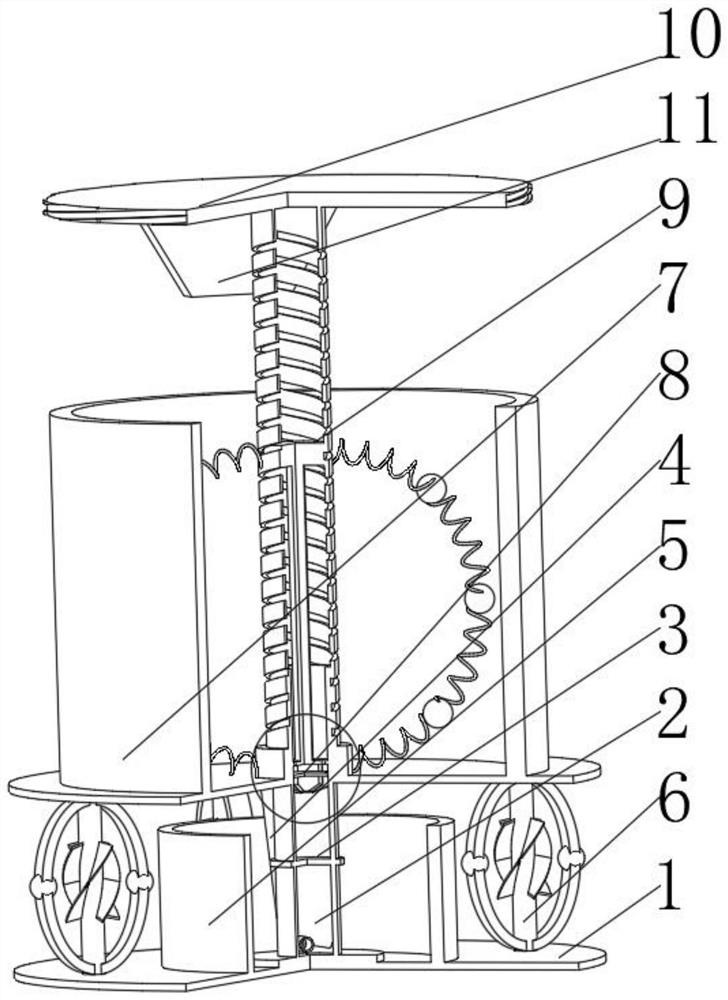

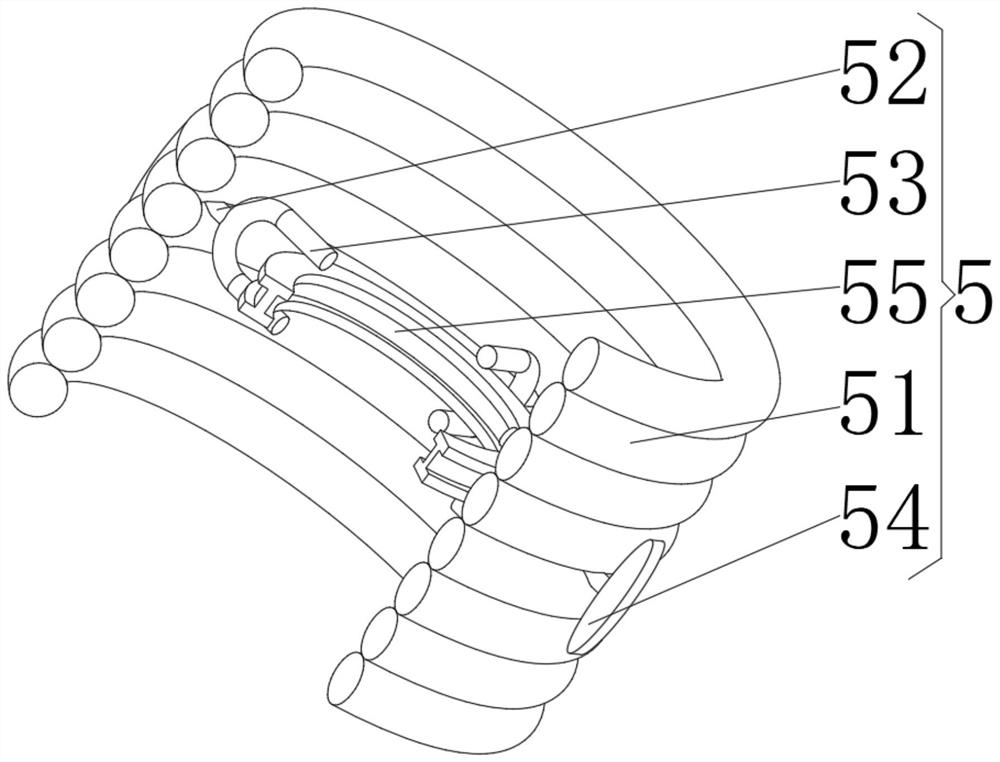

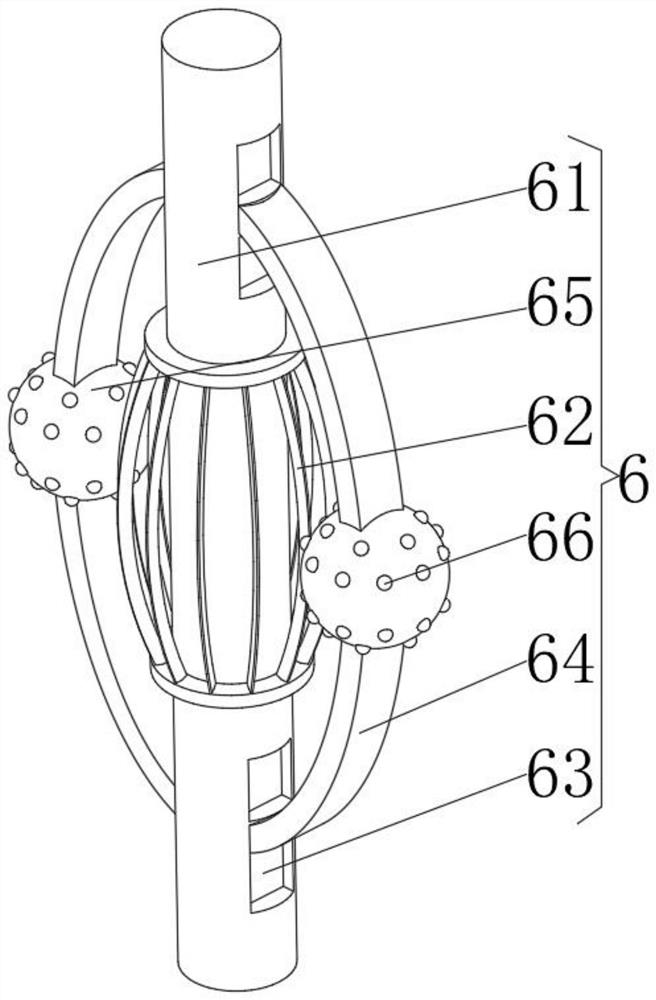

[0039] see Figure 1-5, the present invention provides a technical solution: an electroplating device, including a placement bottom plate 1, a backflow cavity tube 2 fixedly connected to the middle position of the top of the bottom plate 1, a filter core tube 3 movably connected to the top of the backflow cavity tube 2, and an outer side of the backflow cavity tube 2 The front of the surface and the bottom of the back are connected with a return pipe 4, and the top of the bottom plate 1 is located outside the return cavity tube 2 and is fixedly connected with a magnetic control mechanism 5, and the top of the bottom plate 1 is located on the side of the magnetic control mechanism 5 away from the return cavity tube 2. Mechanism 6, the trigger mechanism 6 is movably connected with an electroplating box 7 on the side away from the bottom plate 1, and a pressure applying mechanism 8 is arranged at the middle of the bottom of the inner cavity of the electroplating box 7, and the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com