Coating layer-free light ablation-resistant thermal insulation composite material and preparation method thereof

A composite material, ablation resistance technology, applied in insulation improvement, weight reduction and other directions, to achieve the effect of improving surface ablation resistance and anti-scour performance and overall structural strength, excellent thermal insulation performance, and reducing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] In a first aspect, the present invention provides a method for preparing an uncoated lightweight ablation-resistant and heat-insulating composite material, the method comprising the following steps:

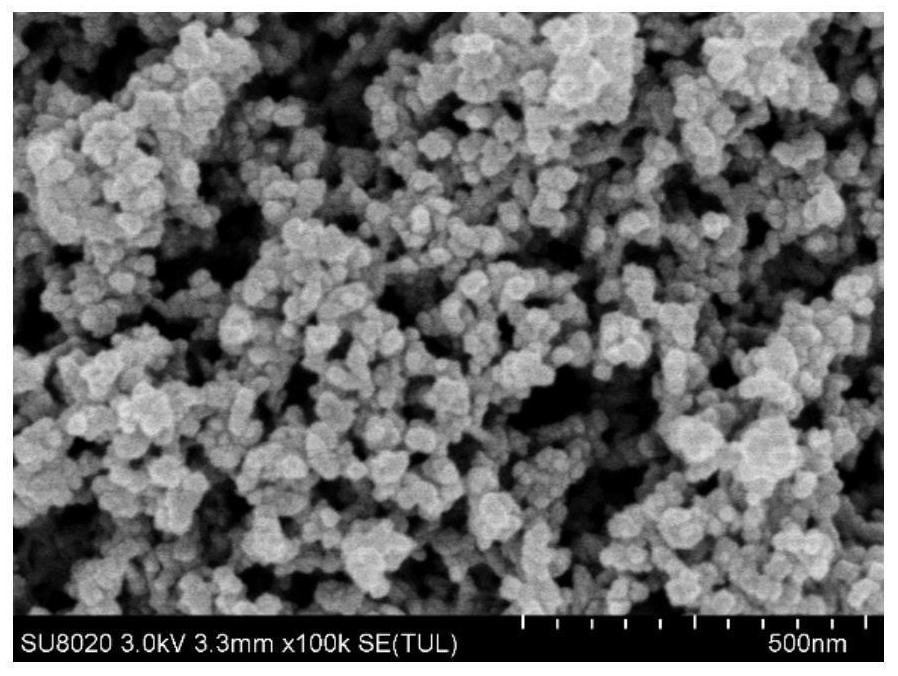

[0029] (1) Mix the phenolic resin and absolute ethanol evenly to obtain an initial solution, then add orthosilicate ethyl ester and distilled water to the initial solution and heat and stir evenly to obtain a mixed solution, and then add six methylenetetramine catalyst and stir evenly to obtain organic-inorganic hybrid precursor glue; in the present invention, it is preferred to add orthosilicate ethyl ester and distilled water to the initial solution and at a temperature of 40 to 60°C ( Such as 40°C, 45°C, 50°C, 55°C or 60°C), after heating and stirring for 4 to 10 hours, the hexamethylenetetramine catalyst is added; in the present invention, the initial solution is first Add tetraethyl orthosilicate and distilled water, heat and stir evenly to obtain a mixed solution, an...

Embodiment 1

[0062] ① First, dissolve the phenolic resin in absolute ethanol, and prepare an initial solution with a solid content of 40% of the phenolic resin. Then, tetraethyl orthosilicate with 40% mass of phenolic resin and distilled water with 20% mass of tetraethyl orthosilicate were added to the initial solution, and stirred at 40° C. for 10 h. Finally, a hexamethylenetetramine catalyst with 15% of the mass of the phenolic resin was added, and the organic-inorganic hybrid precursor glue was obtained after uniform stirring.

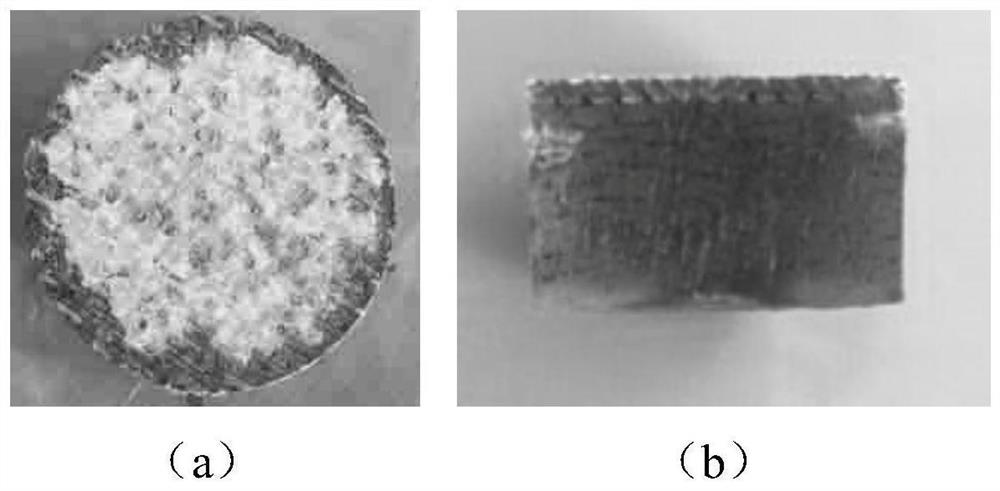

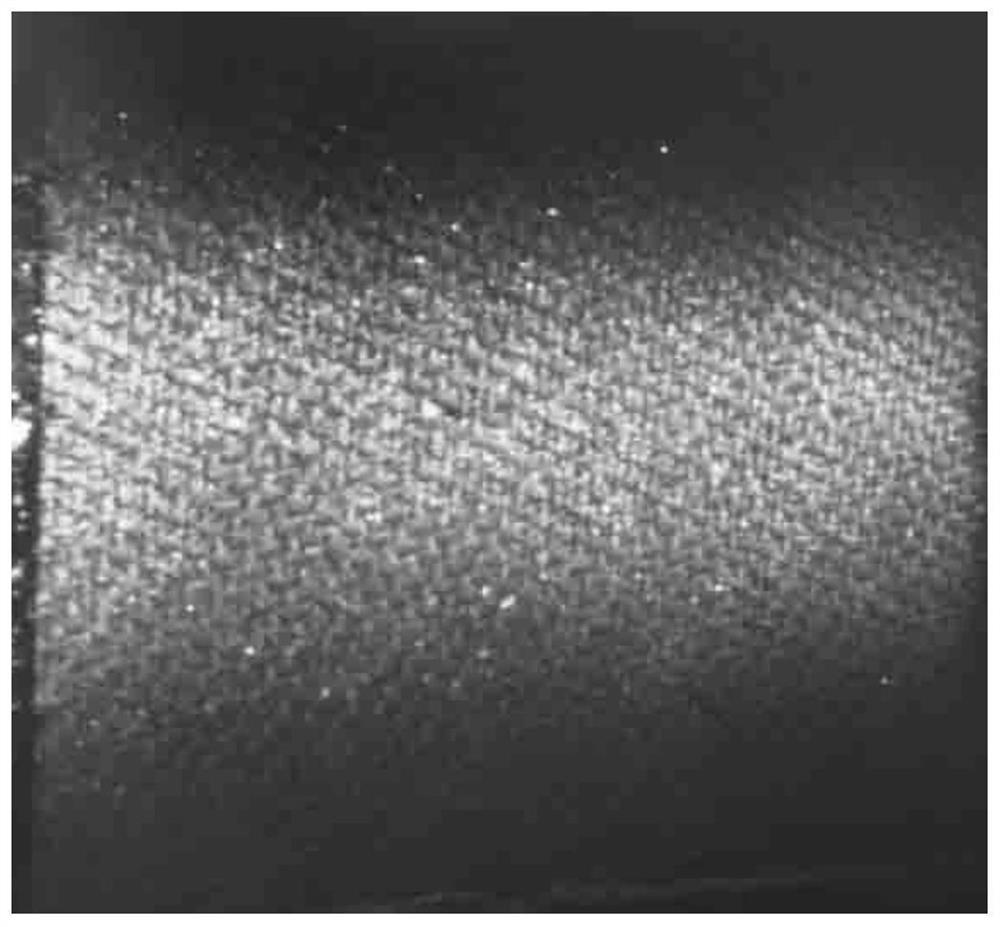

[0063] ②According to the short-term application environment where the surface of the ablation material is 800°C and the duration is ≤600s, the parameters of the multi-density prefabricated body are selected as follows: 2 layers (that is, the surface layer is a structure with a layer of quartz mesh felt between two layers of glass fiber / quartz fiber mixed woven cloth), the equivalent density is 0.9g / cm 3 , the mixed woven fabric is woven by glass fiber / quartz fi...

Embodiment 2

[0069] ① First, dissolve the phenolic resin in absolute ethanol, and prepare an initial solution with a solid content of phenolic resin of 25%. Then, tetraethyl orthosilicate with 40% mass of phenolic resin and distilled water with 20% mass of tetraethyl orthosilicate were added to the initial solution, and stirred at 60° C. for 6 hours. Finally, a hexamethylenetetramine catalyst with 15% of the mass of the phenolic resin was added, and the organic-inorganic hybrid precursor glue was obtained after uniform stirring.

[0070] ②According to the long-term application environment where the surface of the ablation material is 800°C and the duration is ≥1200s, the parameters of the multi-density prefabricated body are selected as follows: 2 layers (that is, the surface layer is a structure with a layer of quartz mesh felt between two layers of glass fiber / quartz fiber mixed woven cloth), the equivalent density is 0.6g / cm 3 , the mixed woven fabric is woven by glass fiber / quartz fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com