Wire winding device for power transmission and distribution engineering construction

A winding device and engineering construction technology, applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of inconvenient removal and inability to control the winding amount of wires well, so as to achieve the convenience of equipment use , the effect of compact wire winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

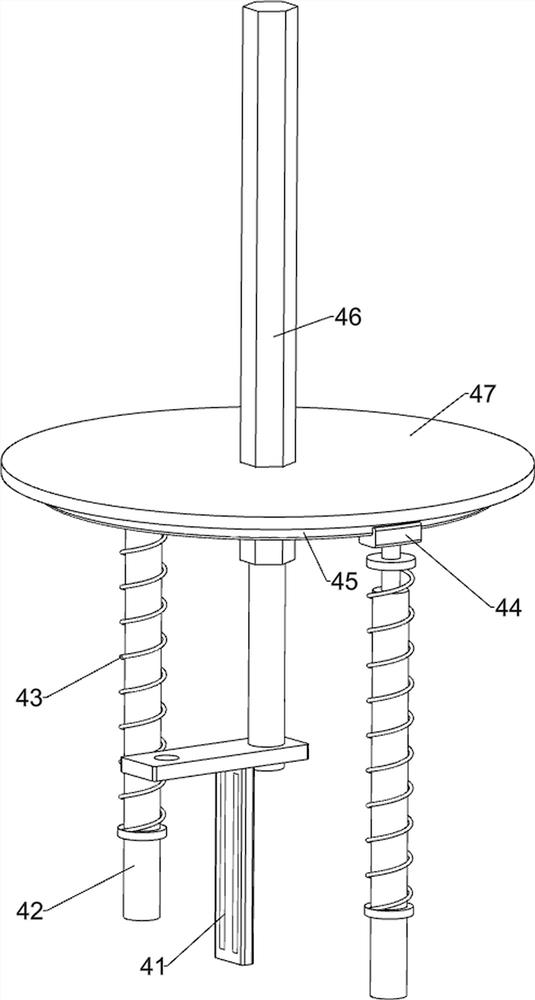

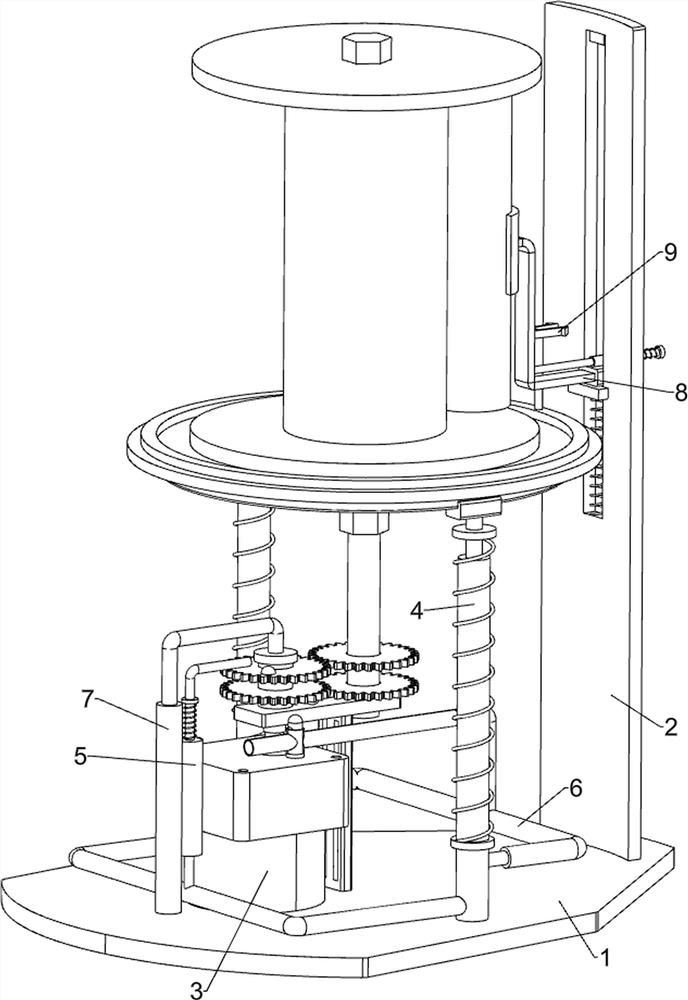

[0027]A wire winding device for power transmission and distribution engineering construction, such asFigure 1-Figure 6As shown, it includes a bottom plate 1, a supporting plate 2, a geared motor 3, a lifting and placing component 4, a control component 5, an air intake component 6 and a bleeder component 7. The top left side of the bottom plate 1 is fixed with a geared motor 3 through bolts. 1 The top right side is fixed with a supporting plate 2 through bolts, the bottom plate 1 is equipped with a lifting placement assembly 4 in the middle of the top, a control module 5 is installed at the top left of the bottom plate 1, and the lifting placement assembly 4 is equipped with an air intake assembly 6 on the right side, which is placed in a lifting position On the left side of the assembly 4 is installed a deflation assembly 7 which is controlled by a lifting method.

[0028]When it is necessary to use the device to wind wires, first place the wire-wound barrel on the lifting and placing...

Embodiment 2

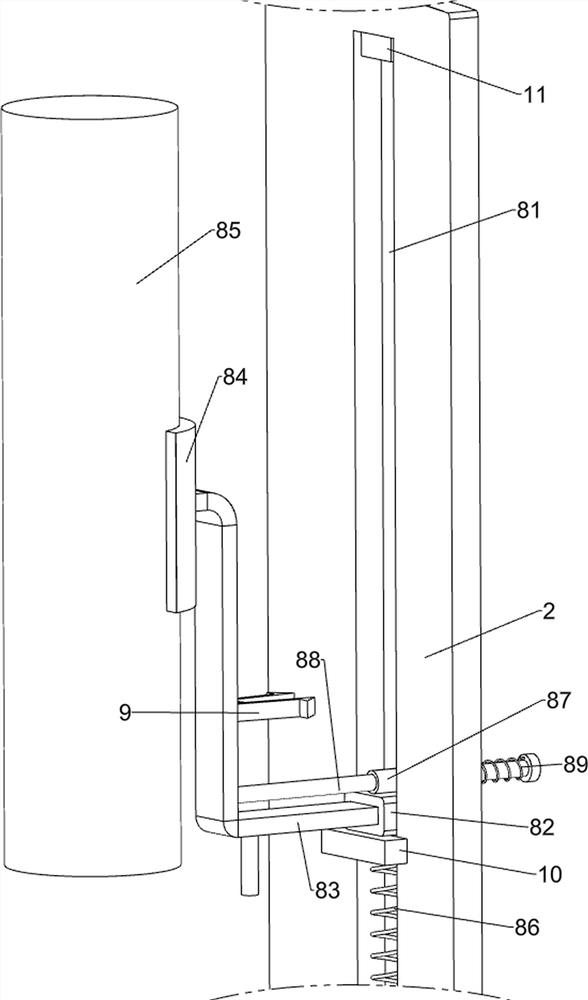

[0038]On the basis of Example 1, such asfigure 1 ,Figure 7 withFigure 8 As shown, it also includes a compaction assembly 8. The upper part of the support plate 2 is equipped with a compaction assembly 8. The compaction assembly 8 includes a square hollow sleeve 82, a sliding plate 83, an arc plate 84, a cylinder 85, a fourth spring 86, The circular sliding sleeve 87, the sliding rod 88 and the fifth spring 89 are provided with a sliding groove 81 on the upper part of the support plate 2, a square hollow sleeve 82 is slidably arranged in the sliding groove 81, and a sliding plate 83 is slidably arranged in the square hollow sleeve 82. An arc plate 84 is welded on the upper left side of the sliding plate 83. The arc plate 84 is provided with a cylinder 85 on the left side. A fourth spring 86 is connected between the bottom of the square hollow sleeve 82 and the support plate 2, and the top of the square hollow sleeve 82 passes A circular sliding sleeve 87 is fixedly connected to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com