Slitting machine winding equipment suitable for plate and strip processing

A slitting machine and equipment technology, which is applied in the directions of coiling strips, thin material processing, transportation and packaging, etc., can solve the problems of hidden safety hazards, time-consuming and labor-intensive problems, and achieve a simple overall structure, low implementation cost, convenient and stable installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

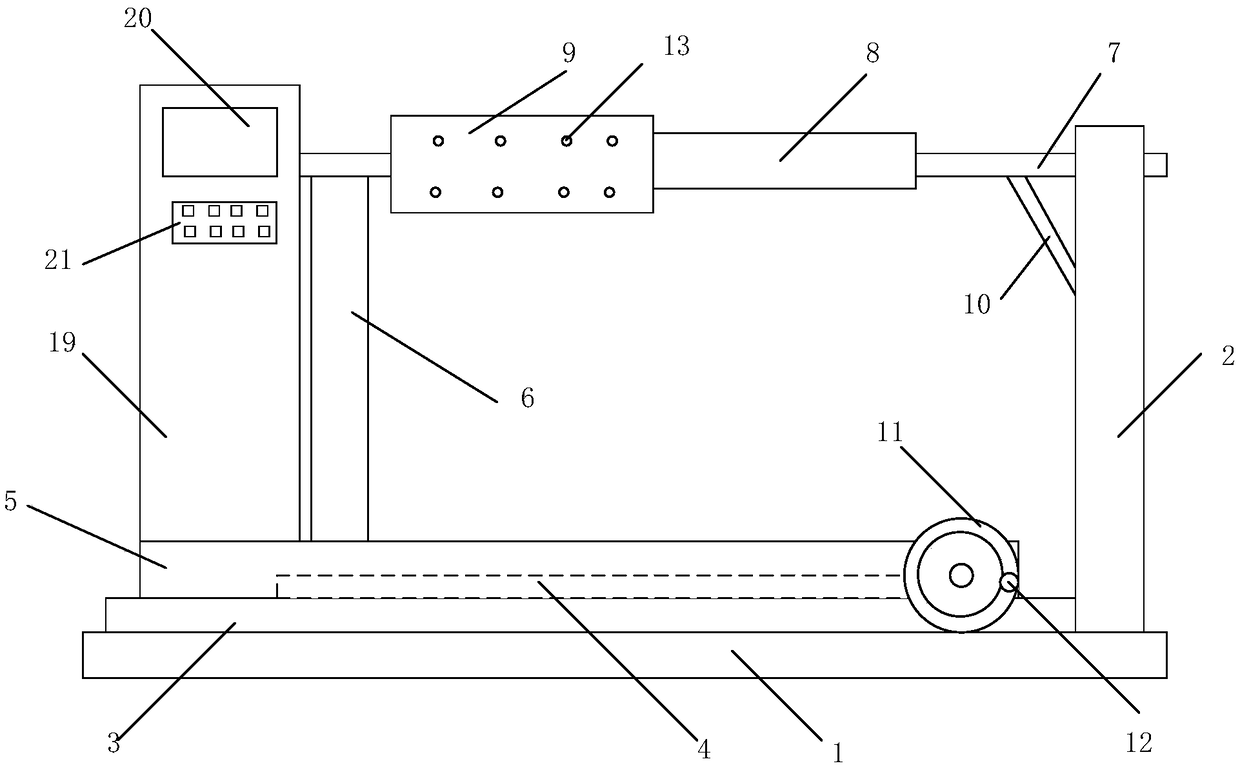

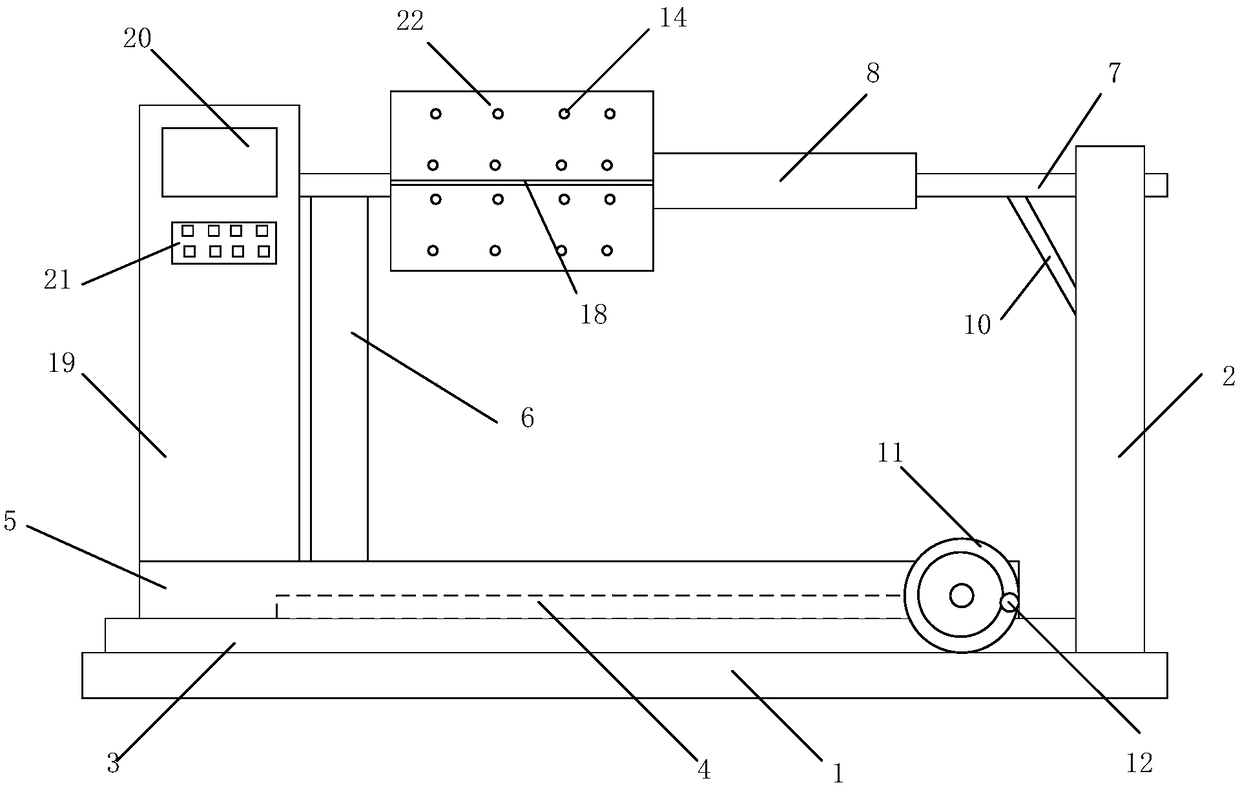

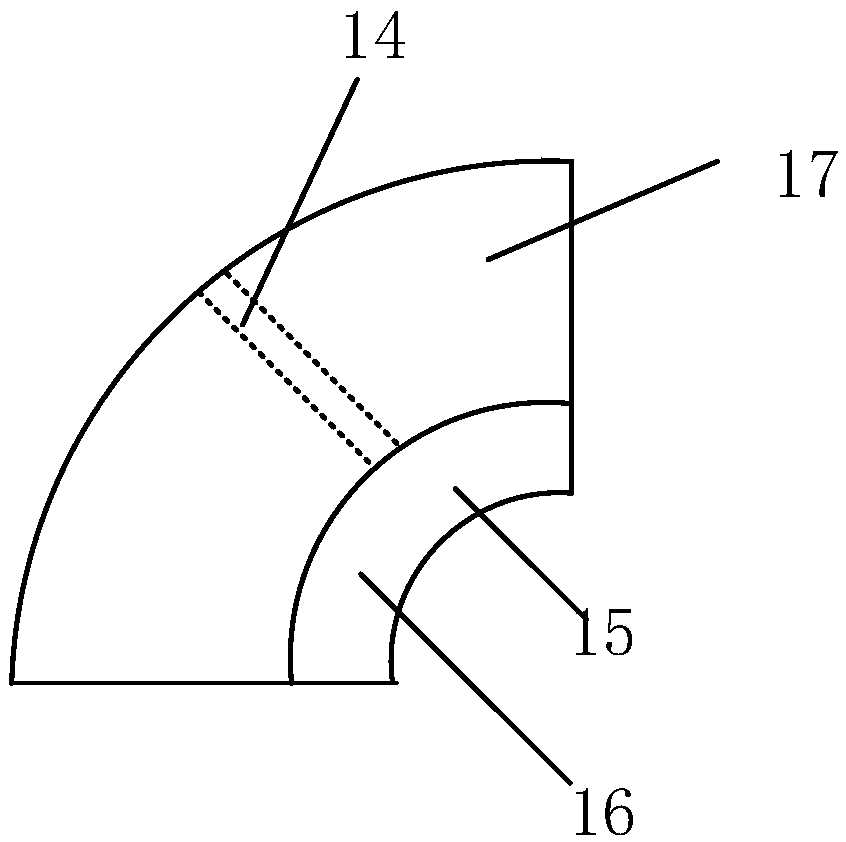

[0034] Such as figure 1 , figure 2 A kind of slitting machine winding equipment suitable for strip processing, including a bearing base 1, one side of the bearing base 1 is provided with an equipment bracket 2, and its difference lies in: in order to facilitate the adjustment of different specifications during subsequent use The strips are preferably rewinded and switched, and a base rail is installed above the bearing base 1 . Specifically, the base track includes a base body 3 , and a guide track 4 is erected on the base body 3 . At the same time, in order to realize convenient position adjustment, a traction slider 5 is connected to the guide track 4 , and a manual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com