Light high-rigidity porous grid carbon fiber honeycomb for space, preparation method and application

A carbon fiber, high-stiffness technology, applied in the field of core material manufacturing, can solve problems such as distortion stress, thermal expansion coefficient mismatch, expansion, etc., and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] According to a second aspect of the present invention, there is provided a method for preparing a light-weight, high-rigidity porous grid carbon fiber honeycomb, which is used to prepare the light-weight, high-rigidity porous grid carbon fiber honeycomb described in the first aspect, comprising the following steps:

[0041] In step (1), the ultra-thin carbon fiber prepreg is prepared by thinning the high-modulus carbon fiber tow by using the ultrasonic-guided expanded fiber method, and compounding it with the resin film layer. The prepreg surface density is ≤80g / m 2 , the resin mass content is controlled between 38% and 44%;

[0042] Step (2), cutting the ultra-thin high-modulus carbon fiber prepreg obtained in step (1) into extremely narrow carbon fiber prepreg belts on the prepreg cutting equipment, and the bandwidth is controlled within the range of 2 to 6 mm;

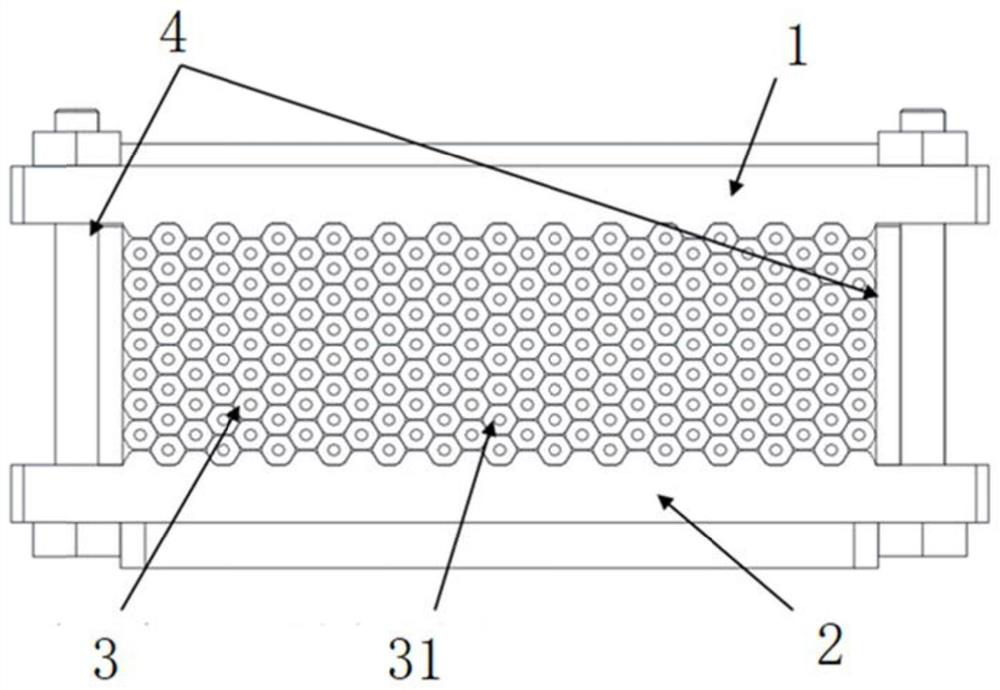

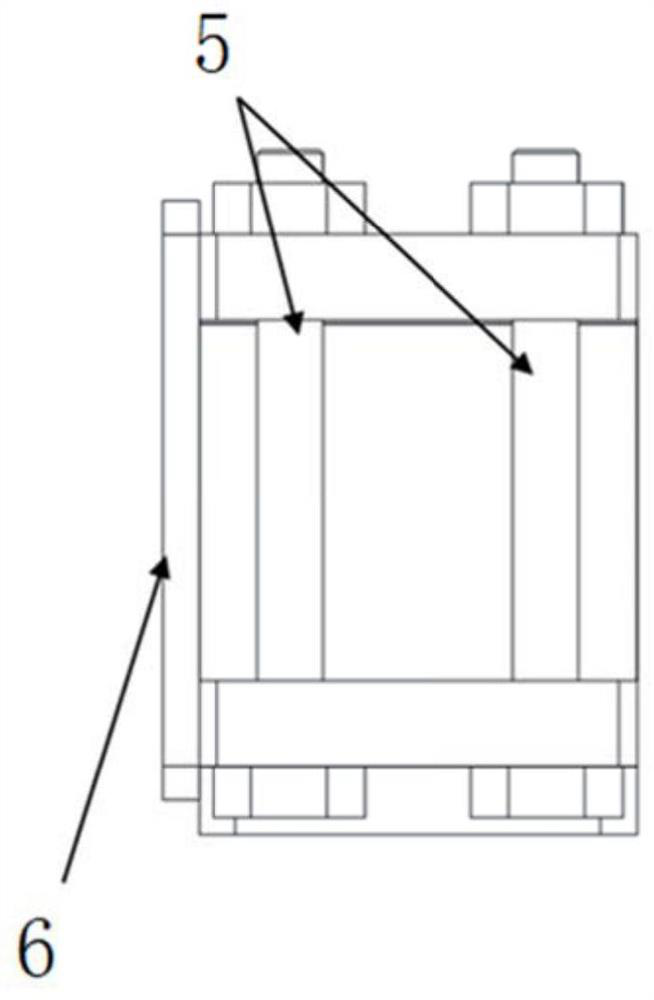

[0043] In step (3), the carbon fiber prepreg extremely narrow tape obtained in step (2) is braided in a tw...

Embodiment 1

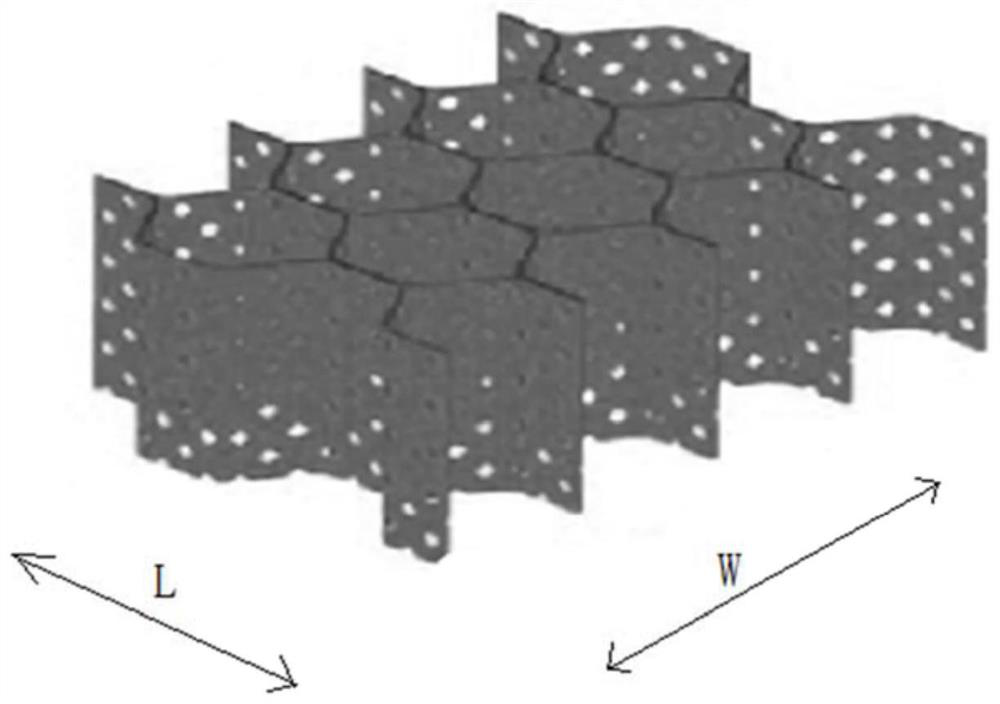

[0059] A light-weight, high-rigidity porous grid carbon fiber honeycomb for space, the honeycomb cell is a hexagonal grid with holes, the side length of the square hole is 1mm; the hole wall material is solidified with porous grid carbon fiber prepreg fabric In the composite material prepared later, the carbon fiber of the honeycomb is M40 high-modulus carbon fiber, and the resin matrix is a toughened epoxy resin that is resistant to temperature changes, vacuum quality damage, and condensable volatiles in space environments. The honeycomb density is 35kg / m 3 , the diameter of the inscribed circle of the cell is Φ10mm, and the thickness of the hole wall is 0.1mm; the weaving form of the porous carbon fiber fabric composite material is plain weave, and the laying direction and the longitudinal angle of the honeycomb are 45°, such as figure 1 shown.

[0060] The method for preparing the space with a lightweight and high-rigidity porous grid carbon fiber honeycomb includes the ...

Embodiment 2

[0072] A light-weight, high-rigidity porous grid carbon fiber honeycomb for space, the honeycomb cell is a hexagonal grid with holes, the side length of the square hole is 0.5mm; the hole wall material is a porous grid carbon fiber prepreg fabric The composite material prepared after curing, the carbon fiber reinforcement of the honeycomb is M40 grade high modulus carbon fiber, and the resin matrix is a toughened epoxy resin that is resistant to temperature changes in space environments, vacuum quality damage, and condensable volatiles. Honeycomb density is 40kg / m 3 , the diameter of the inscribed circle of the cell is Φ8mm, and the thickness of the hole wall is 0.1mm; the weaving form of the porous carbon fiber fabric composite material is twill weave, and the laying direction and the longitudinal angle of the honeycomb are 0°.

[0073] The method for preparing the light-weight and high-rigidity porous grid carbon fiber honeycomb for the space includes the following steps: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com