Golf club head grinding method

A technology for golf club heads and grinding methods, which is applied in the direction of grinding machine tools, grinding devices, manufacturing tools, etc., can solve the problems of time-consuming and labor costs, and achieve the reduction of labor costs, precise control of grinding quantity and grinding quality, and fast The Effect of Grinding Amount and Grinding Quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

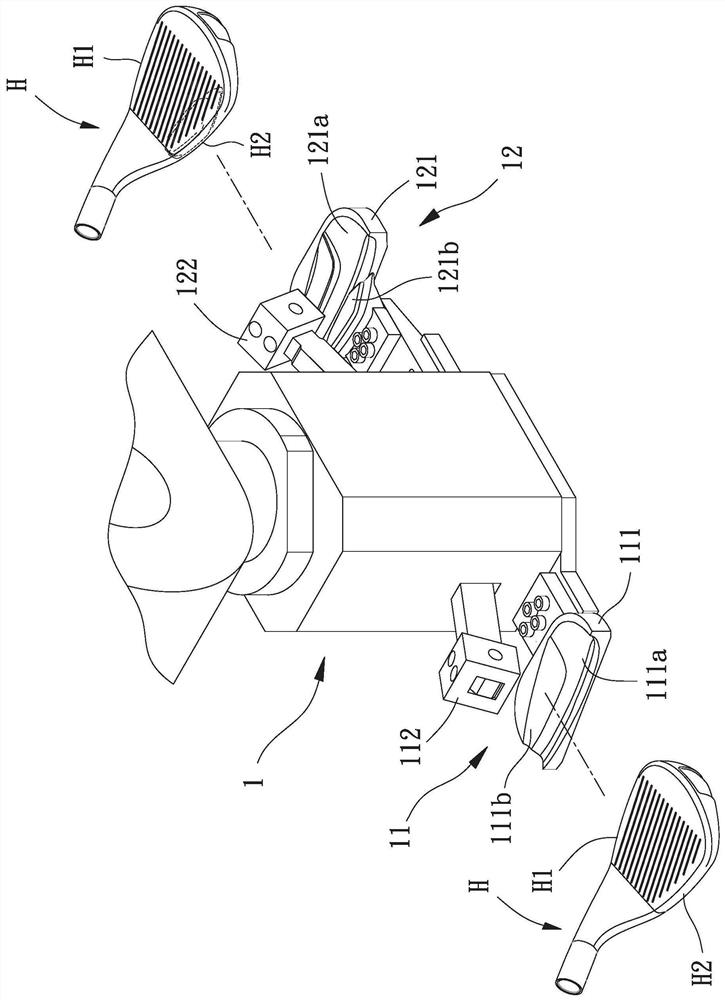

[0047] In order to make the above-mentioned and other objects, features and advantages of the present invention more obvious and easy to understand, the preferred embodiments of the present invention are enumerated below, and are described in detail as follows in conjunction with the accompanying drawings:

[0048] Directionality or similar terms used throughout this disclosure, such as "front", "rear", "left", "right", "top (top)", "bottom (bottom)", "inside", "outside" , "side surface", etc., mainly refer to the directions of the drawings, and each directionality or its similar terms are only used to assist the description and understanding of the various embodiments of the present invention, and are not intended to limit the present invention.

[0049] The use of the quantifier "a" or "an" for the elements and components described throughout the present invention is only for convenience of use and to provide the general meaning of the scope of the present invention; in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com