Medical waste glass medicine bottle recycling and crushing treatment device

A processing device and technology for waste glass, applied in grain processing, solid separation, sieving, etc., can solve the problems of low sufficiency of the crushing process, unable to meet the requirements of crushing and processing waste glass bottles, etc., to promote rapid screening and crushing degree. Elevated, fully enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

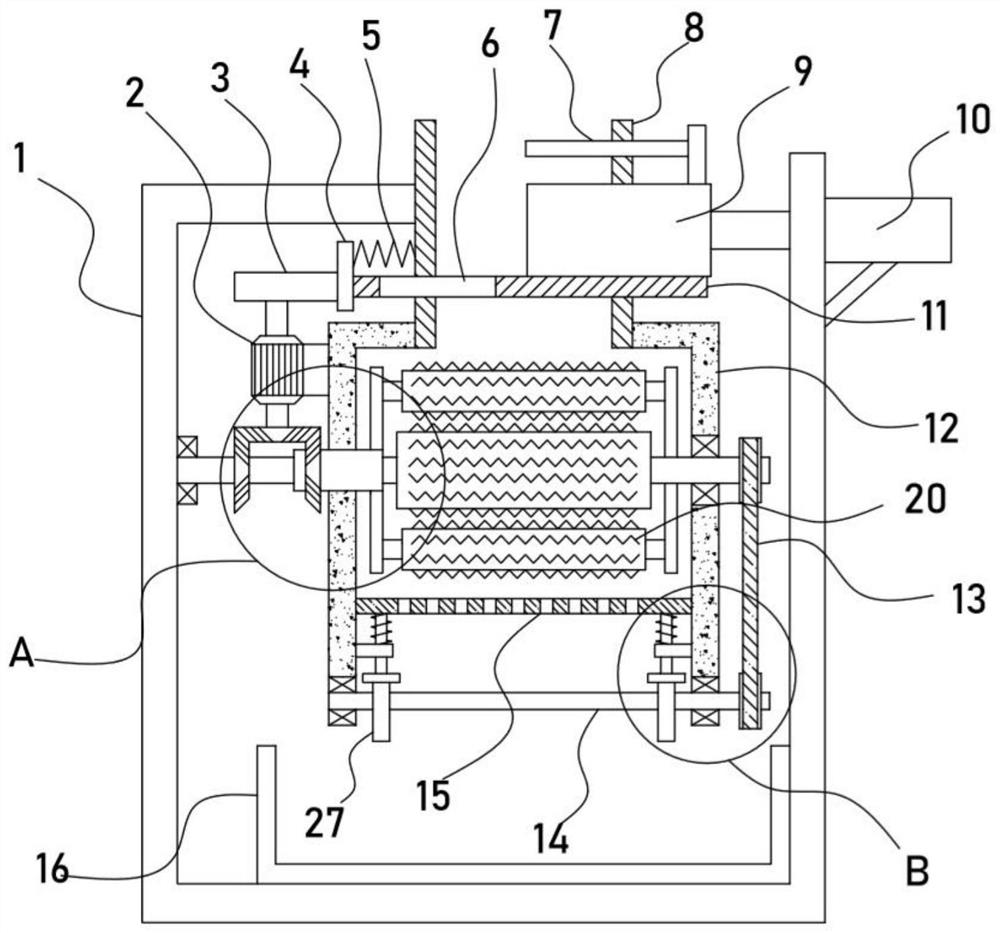

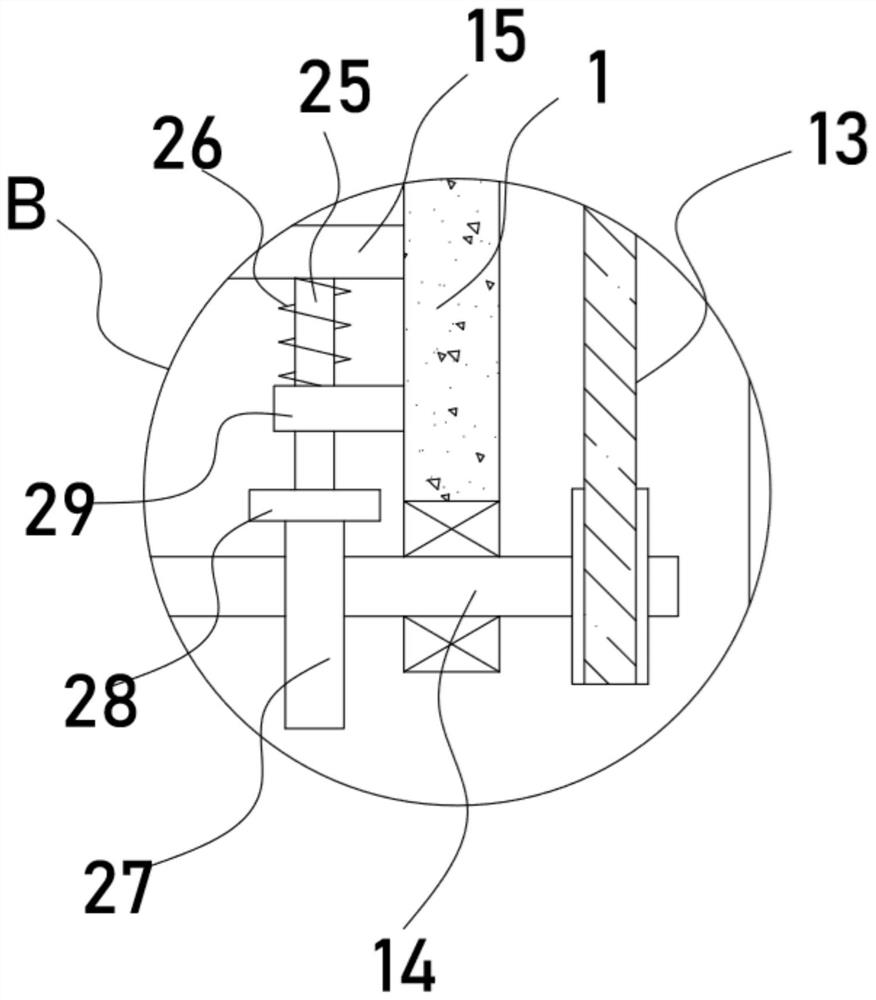

[0022] see Figure 1-4 , a recycling and crushing treatment device for medical waste glass medicine bottles, comprising a support frame 1, a collection tank 16 is fixed on the support frame 1, a crushing box 12 is fixed on the collection tank 16, and a feeding pipe 8 is installed on the crushing box 12. The feeding pipe 8 is provided with a primary crushing mechanism for crushing glass medicine bottles, the crushing box 12 is fixed with a biaxial motor 2, and the biaxial motor 2 is driven and connected with a device that is slidably installed on the feeding pipe 8. Intermittent feeding mechanism, the crushing box 12 is rotatably installed with a rotary crushing mechanism driven by a biaxial motor 2, the sieve plate 15 above the collection tank 16 is slidably installed in the crushing box 12, and the crushing box 12 is A vibrating mechanism for driving the sieve plate 15 to reciprocate is installed in rotation.

[0023] The primary crushing mechanism of the device includes an ...

Embodiment 2

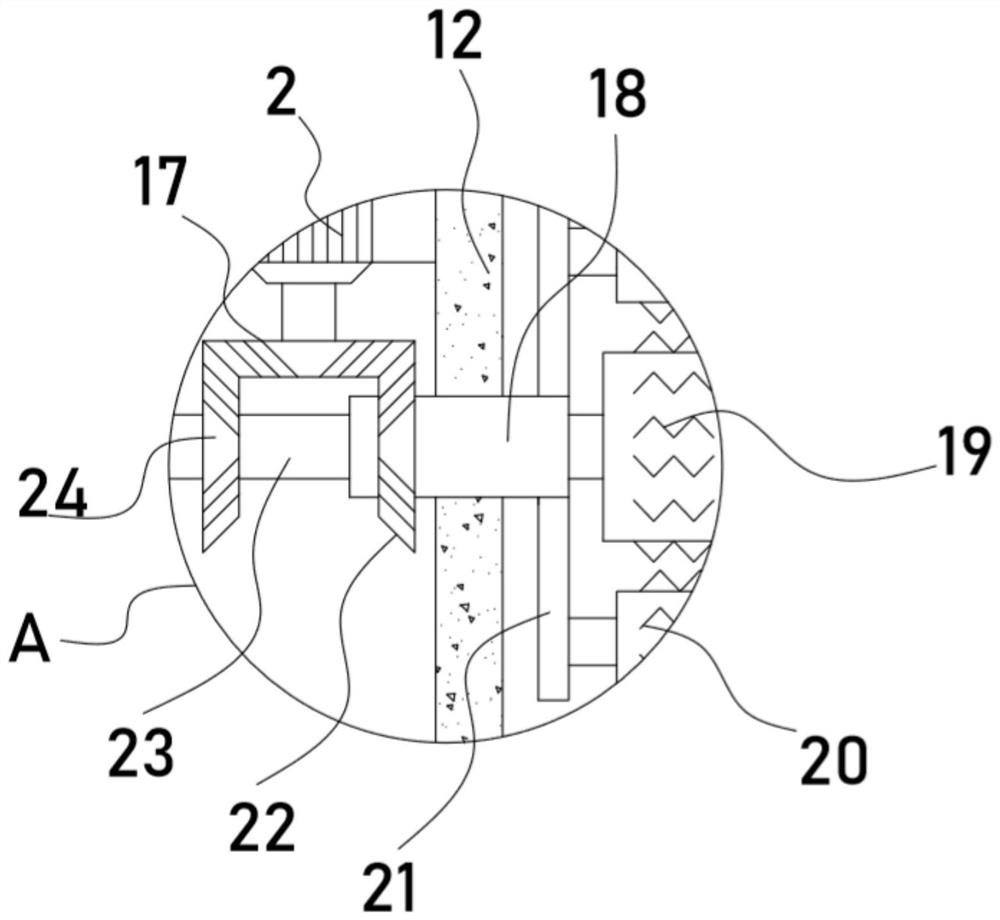

[0028] On the basis of Embodiment 1, in addition, this device is also provided with a rotary crushing mechanism, including a transmission sleeve 18 that is rotatably installed on the crushing box 12. A turret 21 is fixed on the transmission sleeve 18, and the turret 21 is fixed eccentrically. There are two symmetrically arranged surrounding crushing rollers 20 . The rotary crushing mechanism also includes a rotating shaft 23 that rotates through the transmission sleeve 18 , and a central crushing roller 19 between two surrounding crushing rollers 20 is coaxially fixed on the rotating shaft 23 . The rotary crushing mechanism also includes a bevel gear III24 and a bevel gear II22 respectively sheathed and fixed on the rotating shaft 23 and the transmission sleeve 18. The biaxial motor 2 is driven and connected with bevel gears that alternately mesh with the bevel gear III24 and the bevel gear II22. Gear I17.

[0029] The set double-axis motor 2 drives the bevel gear I17 to rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com