Self-circulation type novel sludge degradation bioreactor and operation method thereof

A bioreactor and self-circulating technology, which is applied in biological sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as uneven oil content, components that are easy to agglomerate, and many impurities , to achieve a wide range of application prospects, reduce energy consumption, and avoid energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

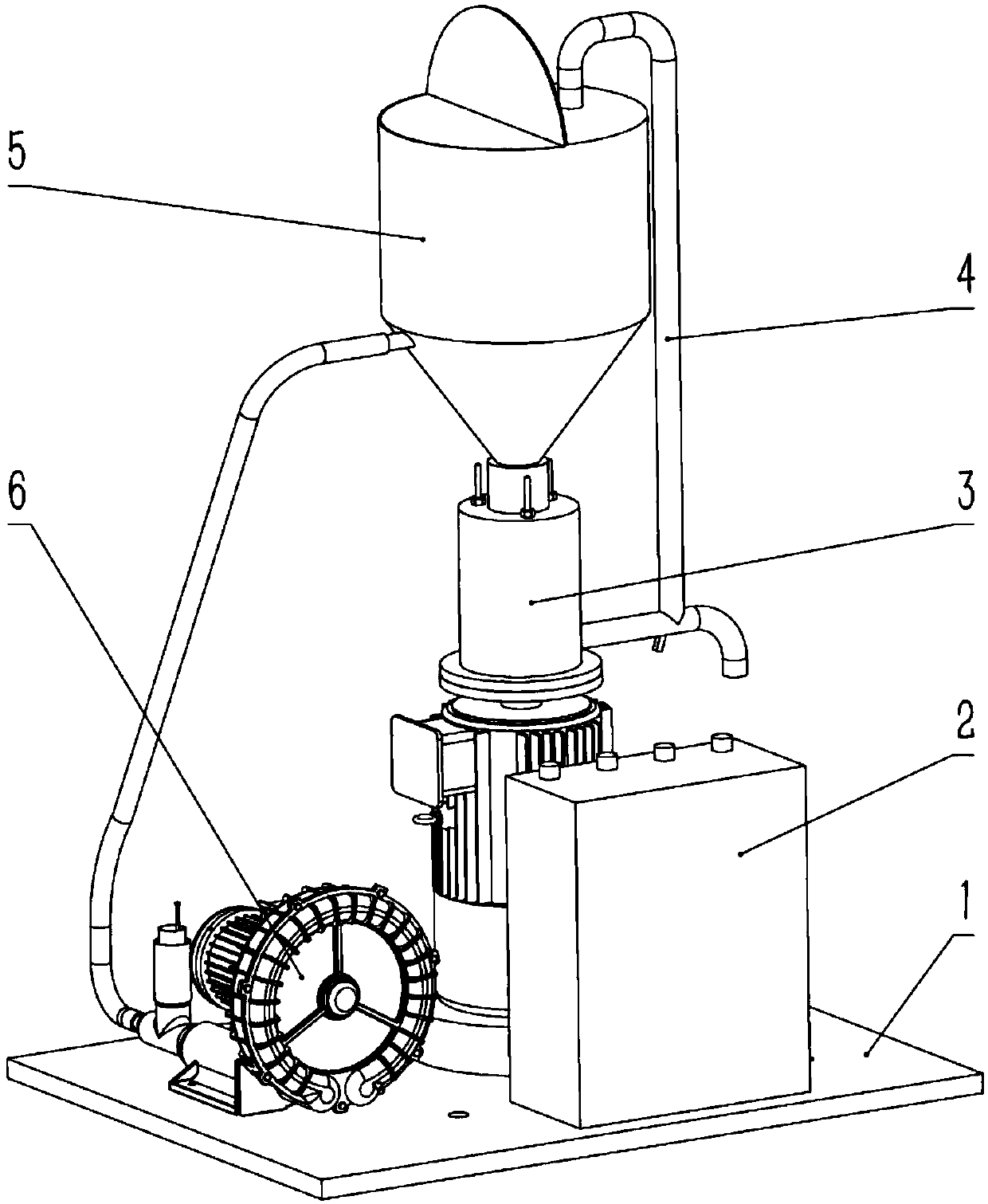

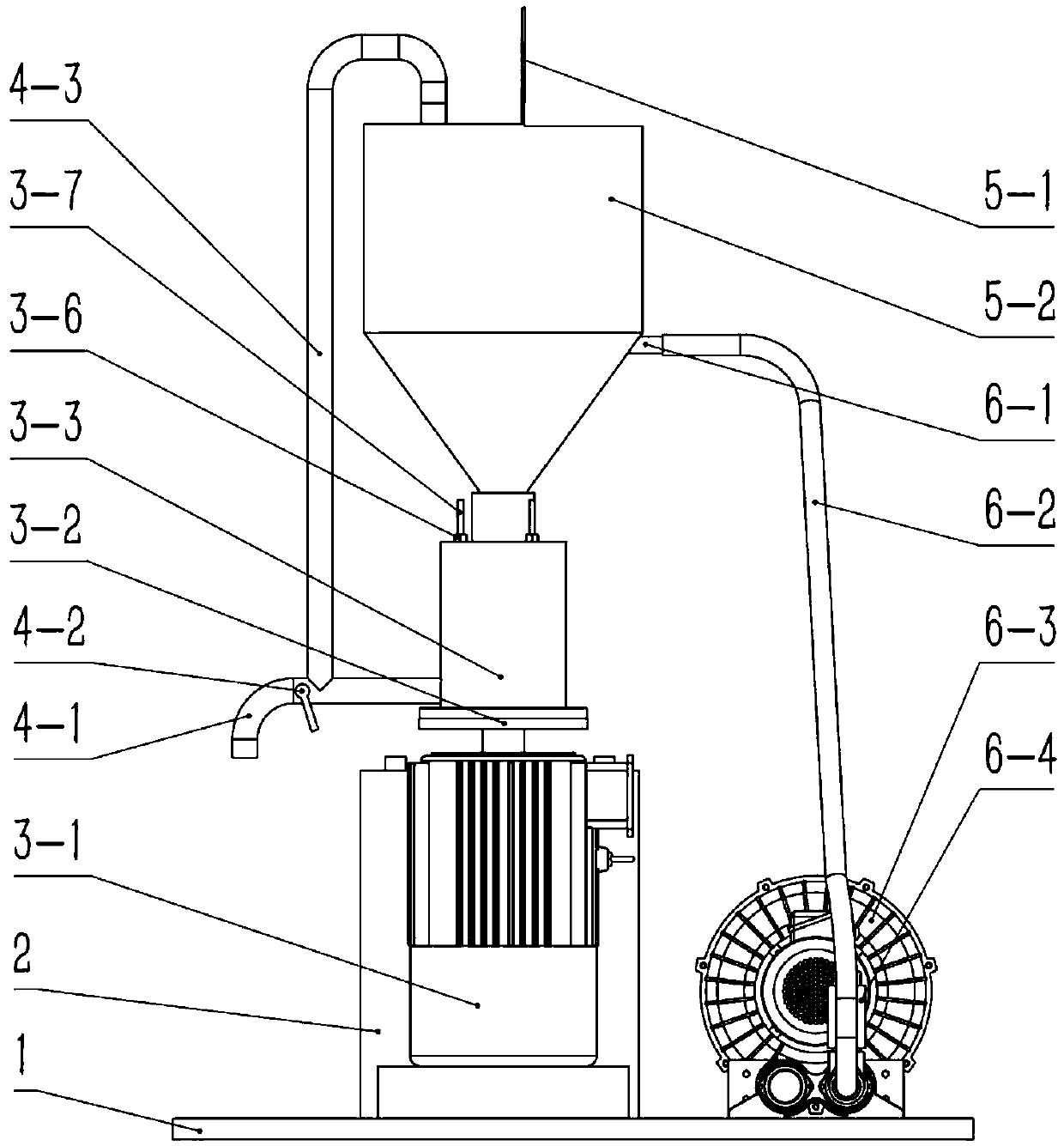

[0048] see figure 1 , a new self-circulating sludge degradation bioreactor of the present invention, comprising: a fixed bottom plate 1, a control mechanism 2, a crushing mechanism 3, a circulation mechanism 4, a reaction vessel 5 and an aeration mechanism 6.

[0049] The fixed bottom plate 1 is a rectangular steel plate with bolt holes, which is used to fix the various mechanisms and devices of the reactor; specifically, the fixed bottom plate 1 can be fixed on the ground through anchor bolts, and the control cabinet, motor, etc. 3-1. The air blower 6-3 is fixed on the fixed bottom plate 1. The function of the fixed base plate 1 is to fix the control cabinet, motor, blower and other devices on the base plate on the one hand, and to fix the whole equipment on the ground on the other hand, so as to avoid the vibration of the equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com