A multifunctional cationic network polymer and its application in the field of sewage purification

A cationic, polymer technology, applied in other chemical processes, alkali metal compounds, water/sewage treatment, etc., can solve problems such as unsatisfactory performance of water adsorption materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In a 50mL single-necked round bottom flask, add 1,2,4,5-tetrakis-(4-pyridyl)benzene (193mg, 0.5mmol) and p-dibromobenzyl (264mg, 1.0mmol) in sequence, and mix well ; Under the protection of nitrogen replacement, N-methylpyrrolidone (25 mL) was added by injection as a reaction solvent, and then the temperature was raised to 80° C. for heating and stirring for 72 hours. After the system was cooled to room temperature, the obtained solid was filtered, washed thoroughly with solvents such as N,N-dimethylformamide, methanol, tetrahydrofuran, acetone, ether, etc., and heated and dried at 80°C for 6 hours to obtain a light brown solid powder That is, the cationic network polymer material CON-LDU3, the weighed product is 450 mg, and the calculated product yield is 98%.

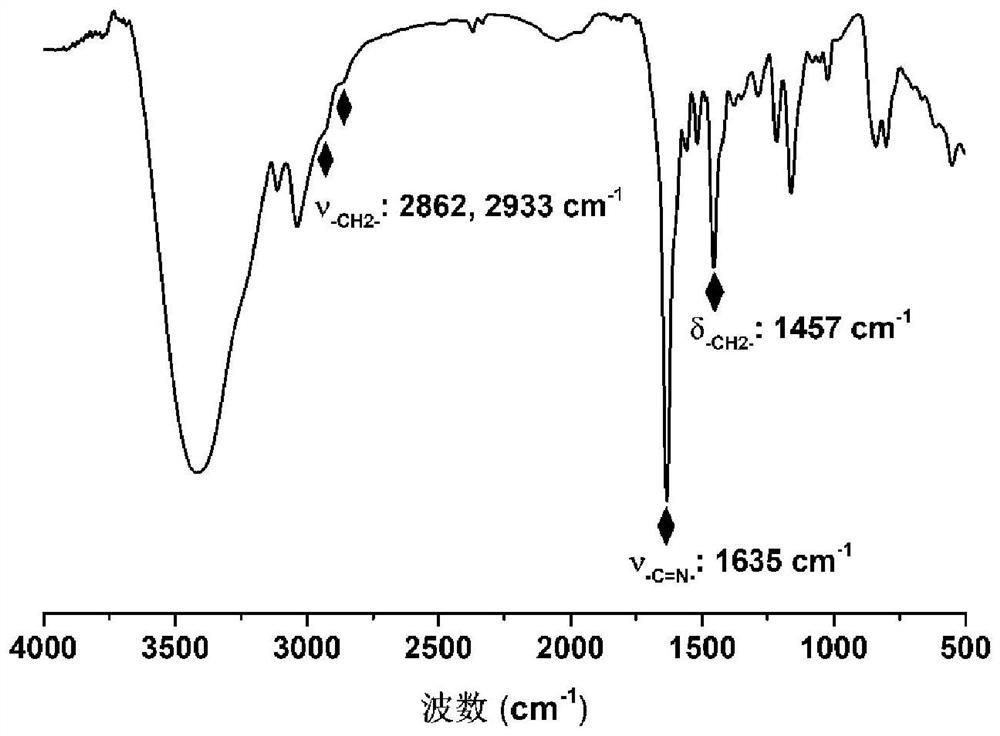

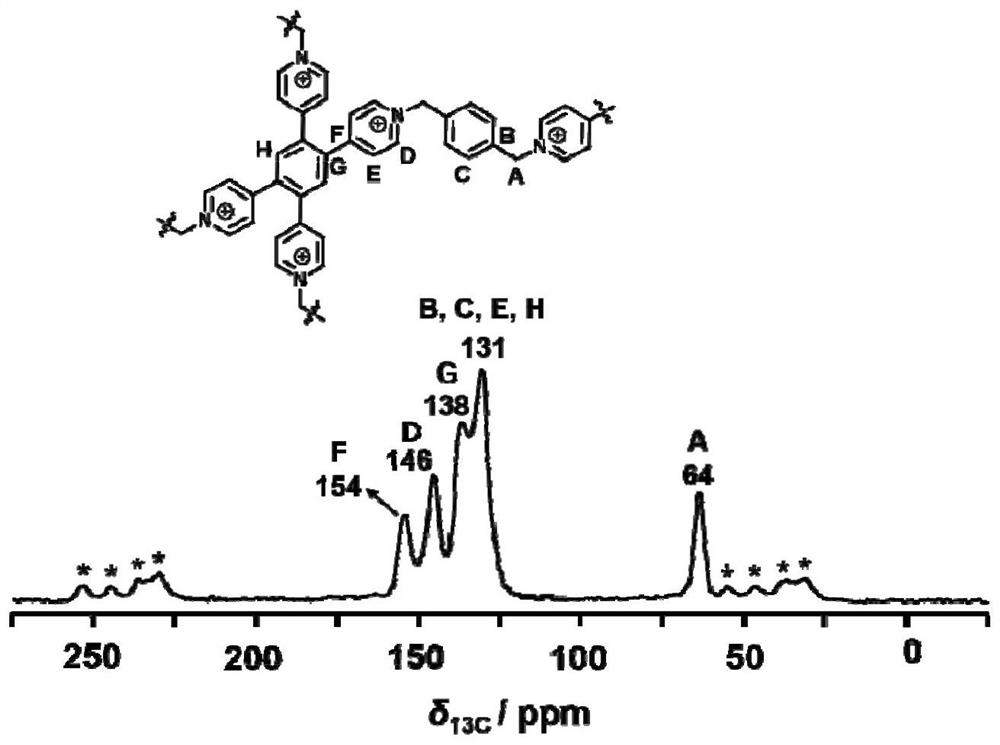

[0042] Such as figure 1 Shown is the Fourier transform infrared spectrum of the network polymer CON-LDU3, visible, 2862-2933cm -1 and 1457cm -1 The signals at can be referred to respectively as -CH 2 - the ...

Embodiment 2

[0047] In a 50mL single-necked round bottom flask, add 1,2,4,5-tetrakis-(4-pyridyl)benzene (193mg, 0.5mmol) and p-dibromobenzyl (396mg, 1.5mmol) in sequence, and mix well ; Under the protection of nitrogen replacement, N-methylpyrrolidone (25 mL) was added by injection as a reaction solvent, and then the temperature was raised to 80° C. for heating and stirring for 72 hours. After the system was cooled to room temperature, the resulting solid was filtered, washed thoroughly with solvents such as N,N-dimethylformamide, methanol, tetrahydrofuran, acetone, ether, etc., and then heated and dried at 80°C for 6 hours. The obtained light brown solid powder was It is a cationic network polymer material CON-LDU3.

Embodiment 3

[0049] In a 50mL single-necked round bottom flask, add 1,2,4,5-tetrakis-(4-pyridyl)benzene (193mg, 0.5mmol) and p-dibromobenzyl (264mg, 1.0mmol) in sequence, and mix well ; Under the protection of nitrogen replacement, acetonitrile (25 mL) was added by injection as a reaction solvent, and then the temperature was raised to 80° C. for heating and stirring for 72 hours. After the system was cooled to room temperature, the obtained solid was filtered, washed thoroughly with solvents such as N,N-dimethylformamide, methanol, tetrahydrofuran, acetone, ether, etc., and heated and dried at 80°C for 6 hours to obtain a light brown solid powder It is the cationic network polymer material CON-LDU3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com