Multi-stage reaction kettle

A multi-stage reaction, kettle body technology, applied in chemical/physical/physical-chemical fixed reactors, chemical/physical/physical-chemical processes, chemical instruments and methods, etc., can solve the problem that production efficiency cannot be substantially improved, Unfavorable production efficiency, waste of resources and other problems, to achieve the effect of improving utilization, optimizing product performance, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

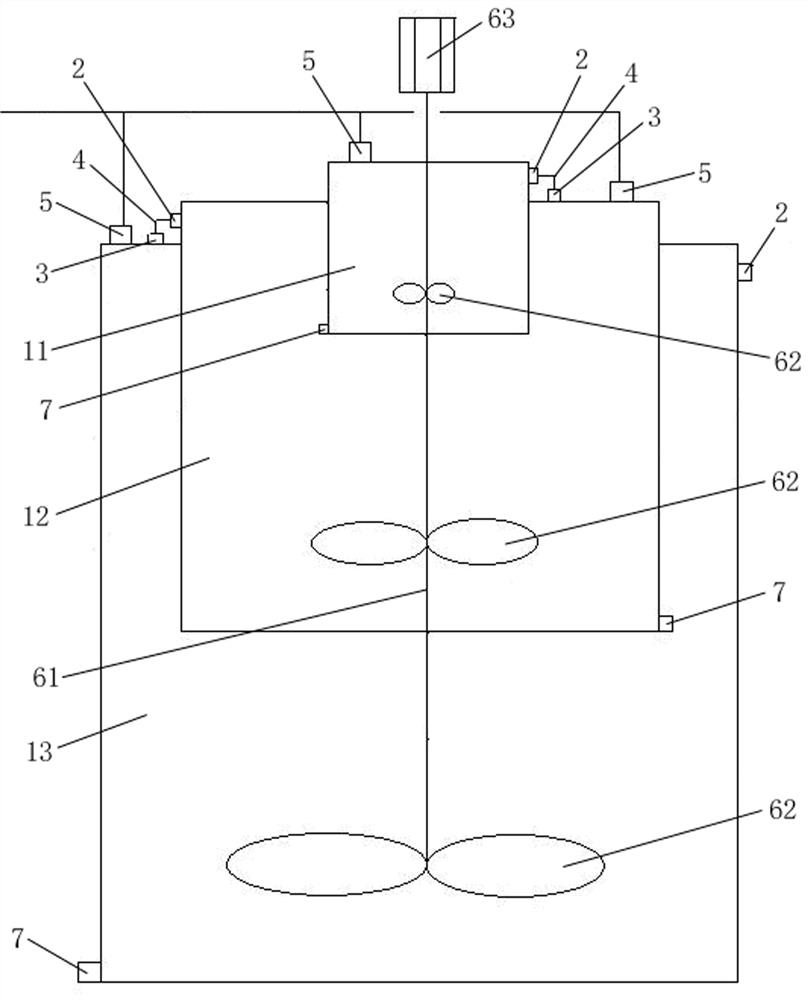

[0020] A multi-stage reactor for preparing narrowly distributed ternary precursors, taking three-stage as an example, such as figure 1 As shown, it includes three kettle bodies that are set sequentially from top to bottom and from inside to outside. Each level of kettle body has an overflow port 2 on the side wall close to its own top cover, and each level of kettle body is provided with an overflow The end of the port is exposed as a non-sleeved end, that is to say, viewed from the inside to the outside, the part below the overflow port of the first-stage kettle body 11 is embedded in the second-stage kettle body 12, and the second-stage kettle body 12 is embedded in the second-stage kettle body 12. The part below the overflow port of the first-stage still body 12 is embedded in the third-stage still body 13 . Starting from the second stage kettle body 12, each stage kettle body is provided with a material receiving port 3 for receiving the material output from the overflow p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com