Preparation method of microcapsule fire extinguishing agent taking dibromomethane as core material

A technology of dibromomethane and microcapsules, which is applied in the field of preparation of microcapsule fire extinguishing agents, can solve the problems of unresolved fire extinguishing agent coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

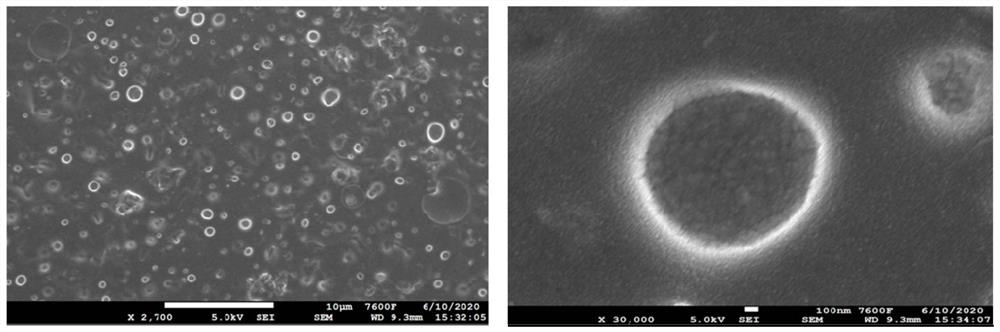

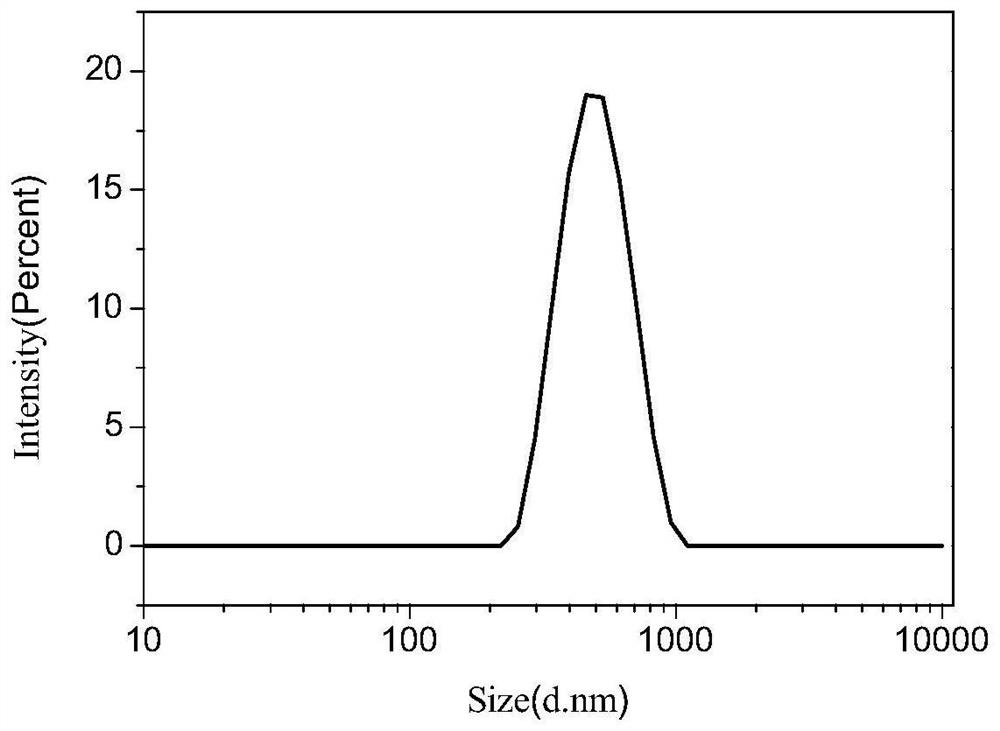

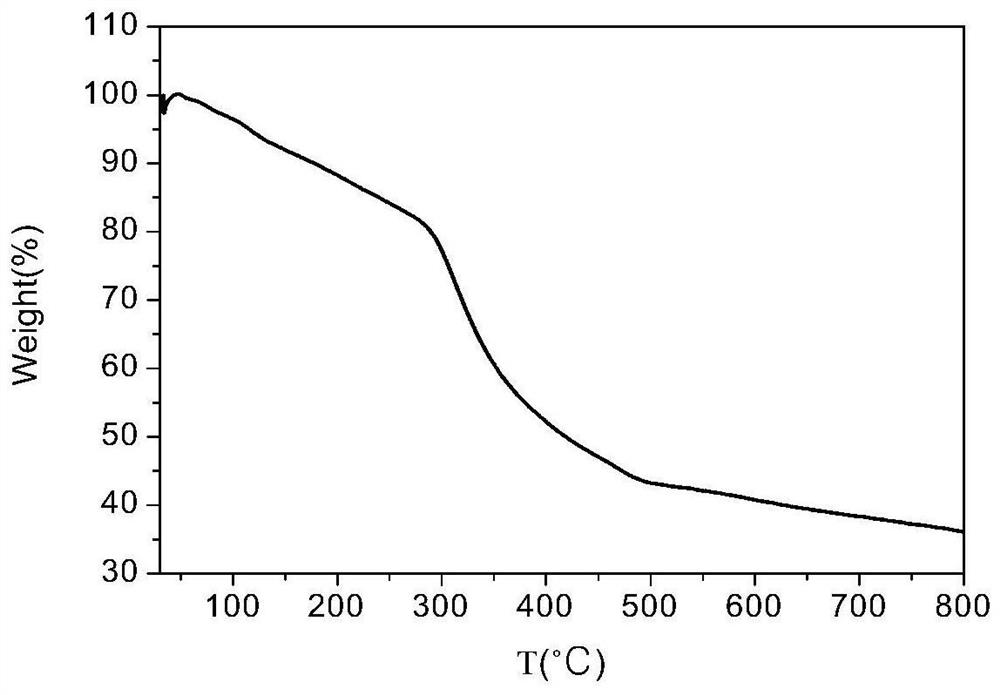

[0030] Taking dibromomethane as the preparation method of the microcapsule fire extinguishing agent of core material, comprises the following steps:

[0031] (1) Preparation of wall material solution: Prepare gelatin aqueous solution with a concentration of 3%, sodium polyphosphate aqueous solution with a concentration of 5%, and montmorillonite solution with a concentration of 0.05%.

[0032] (2) Preparation of emulsion: Measure 50mL of 3% gelatin aqueous solution in a flask, slowly add 2mL of dibromomethane into the flask, stir and emulsify at 40°C for 5 minutes at a speed of 4000r / min, then add 10mL of 5% polymer Sodium phosphate aqueous solution and 20mL 0.05% montmorillonite solution were added with 0.3g Span80 and stirred for 10min to form a stable and uniform emulsion.

[0033] (3) Formation of microcapsules: Add 10% sulfuric acid solution to adjust the pH to about 4.0, keep 1000r / min, react at 30°C for 1h, lower the system temperature to below 10°C, add 2mL of curing a...

Embodiment 2

[0041] (1) Preparation of wall material solution: Prepare gelatin aqueous solution with a concentration of 5%, sodium polyphosphate aqueous solution with a concentration of 5%, and montmorillonite solution with a concentration of 0.1%.

[0042] (2) Preparation of emulsion: Measure 50mL of 5% gelatin aqueous solution in a flask, slowly add 2mL of dibromomethane into the flask, stir and emulsify at 40°C for 5 minutes at a speed of 5000r / min, then add 5mL of 5% polymer Sodium phosphate aqueous solution and 28mL 0.1% montmorillonite solution were added with 0.2g Span80 and 0.1g Tween20 and stirred for 5min to form a stable and uniform emulsion.

[0043] (3) Formation of microcapsules: Add 10% sulfuric acid solution to adjust the pH to about 4.0, keep at 2000r / min, react at 30°C for 1h, lower the system temperature to below 10°C, add 2mL of curing agent glutaraldehyde for 1h, then Slowly raise the temperature to 25°C and react for 2h.

[0044] (4) Drying treatment of microcapsules...

Embodiment 3

[0046] (1) Preparation of wall material solution: prepare 3% gelatin aqueous solution, 3% sodium polyphosphate aqueous solution and 0.5% montmorillonite solution respectively.

[0047](2) Preparation of emulsion: Measure 50mL of 3% gelatin aqueous solution in a flask, slowly add 2mL of dibromomethane into the flask, stir and emulsify at 40°C for 5 minutes at a speed of 4000r / min, then add 10mL of 3% polymer Sodium phosphate aqueous solution and 10mL 0.5% montmorillonite solution were added with 0.2g Tween20 and stirred for 10min to form a stable and uniform emulsion.

[0048] (3) Formation of microcapsules: Add 10% sulfuric acid solution to adjust the pH to about 4.0, keep 1000r / min, react at 30°C for 1h, lower the system temperature to below 10°C, add 2mL curing agent glutaraldehyde for 1h, then Slowly raise the temperature to 25°C and react for 2h.

[0049] (4) Drying treatment of microcapsules: wash the microcapsules with deionized water at least 3 times, centrifuge and va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com