Preparation method of peanut polypeptide hot dry noodle blank

A technology of peanut polypeptide and hot-dried noodles, which is applied to the functions of food ingredients, protein-containing food ingredients, protein components of waste, etc., can solve the problems of protein loss, quality reduction, moisture loss, etc., and achieve low cost and long storage time The effect of prolonging and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Mix peanut meal and water at a ratio of 1:4g / mL to liquid, and conduct microwave treatment. The treatment time is 50min, and the treatment temperature is 45°C;

[0035] 2) Add 22ppm alkaline protease to the microwave-treated mixture, and fully stir at 43°C for enzymolysis, and the enzymolysis time is 6h;

[0036] 3) Centrifuge the mixture after enzymolysis at 5900r / min for 20min;

[0037] 4) The precipitate after centrifugation was dissolved in 3 times the volume of the NaCl eluent, and subjected to gel filtration chromatography, wherein the concentration of the eluent was 0.15mol / L , with a flow rate of 0.16mL / min, collect the eluate, and centrifuge for 20min at a speed of 5900r / min;

[0038] 5) Freeze-dry the centrifuged substance in step 4) for 96 hours, and ultrafinely pulverize it for 23 seconds under the condition of a rotating speed of 4700 r / min to obtain peanut polypeptide powder with a molecular weight of 2-7 kDa.

[0039] 6) 100 parts by weight of high-g...

Embodiment 2

[0042] With embodiment 1, difference is that in step 1), the time of microwave treatment is 45min. In step 2), 22ppm alkaline protease was added to the mixed solution, and the enzymatic hydrolysis time was 5.5h.

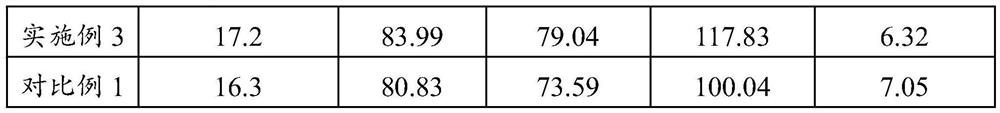

Embodiment 3

[0044] With embodiment 1, difference is that in step 1), the time of microwave treatment is 40min. In step 2), 20 ppm alkaline protease was added relative to the mixture, and the enzymatic hydrolysis temperature was 40°C. 1 part by weight of peanut polypeptide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com