Boron trichloride production method

A boron trichloride and manufacturing method technology, applied in chemical instruments and methods, boron halide compounds, carbon compounds, etc., can solve problems such as the complexity of the boron trichloride manufacturing process, and achieve the effect of difficult to block and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

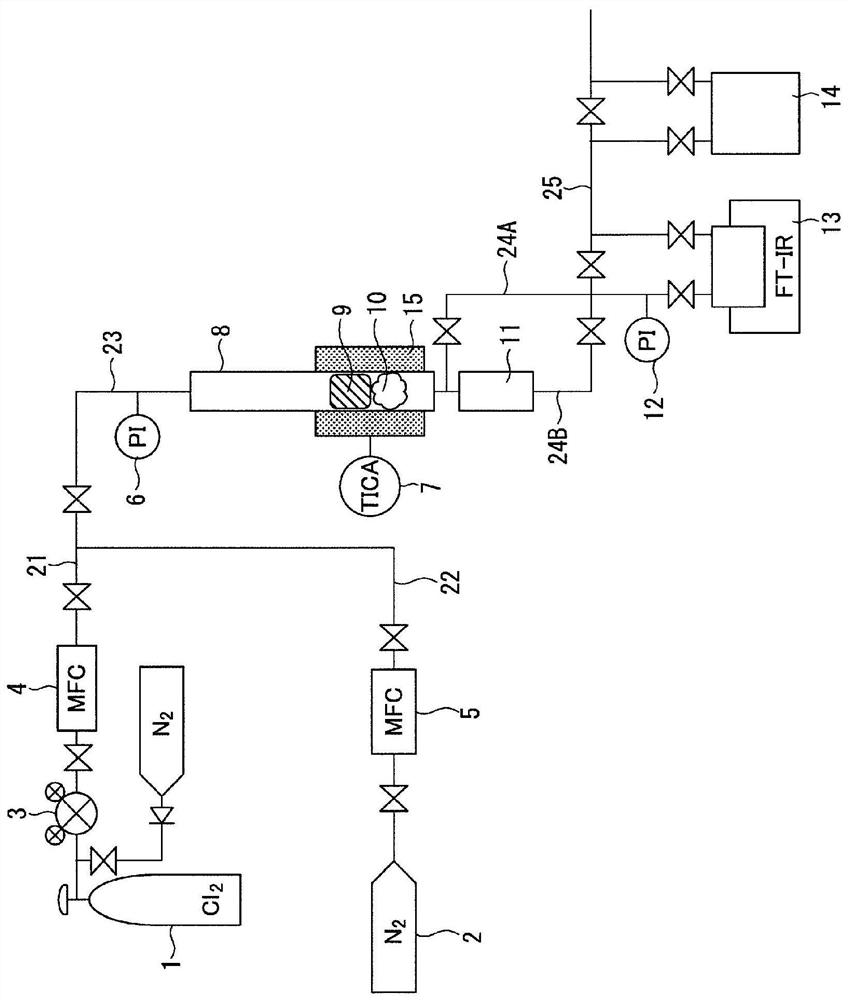

[0087] use with figure 1 The boron trichloride production device having the same configuration as the boron trichloride production device performs the same operation as the above-mentioned embodiment, and reacts the powder of the raw material boron carbide with the gas containing chlorine to produce boron trichloride.

[0088] As the chlorine-containing gas, commercially available high-purity chlorine gas having a purity of 99.999% by volume and a water content of 0.9 ppm by volume was used.

[0089] As the raw material boron carbide powder, a boron carbide powder having a D95 of 48 μm measured by a laser diffraction method was used. In addition, the types and contents of metals other than boron contained in the raw material boron carbide powder are as follows. That is, 0.30% by mass of iron, 0.027% by mass of aluminum, 0.037% by mass of calcium, 0.012% by mass of chromium, and 0.78% by mass of silicon.

[0090] Fill 0.3 g of the powder of boron carbide as the raw material i...

Embodiment 2

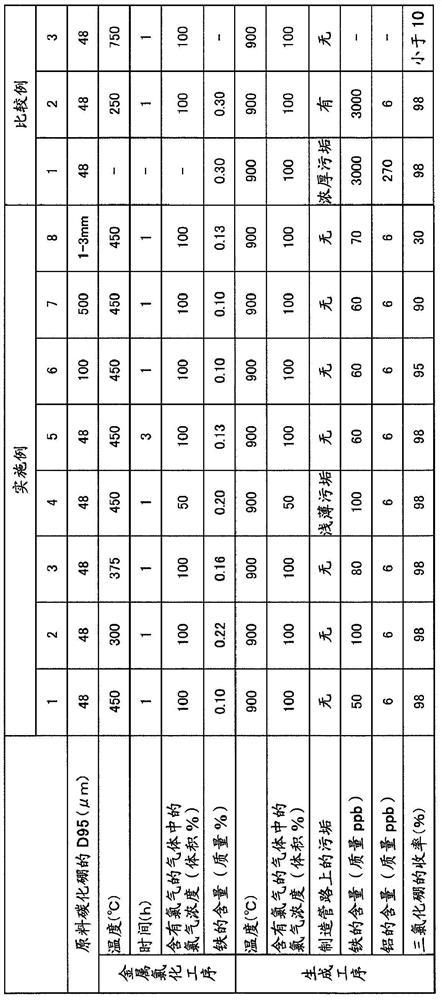

[0096] Except that the temperature for chlorinating the metal and the temperature for removing the metal chloride by reacting the metal contained in the raw material boron carbide powder with chlorine gas were set to 300° C., the same procedure as in Example 1 was carried out to produce three boron chloride. As a result, the iron content in the boron carbide from which the metal chloride was removed was 0.22% by mass. In addition, in the production reaction of boron trichloride, colored fouling thought to be metal chloride was not seen on the production pipeline of the boron trichloride production equipment, and the production pipeline of the boron trichloride production equipment did not occur clogged. Furthermore, the content of iron in the generated boron trichloride was 100 ppb by mass, and the content of aluminum was 6 ppb by mass. In addition, the yield of boron trichloride was 98%.

Embodiment 3

[0098] Except that the temperature for chlorinating the metal and the temperature for removing the metal chloride by reacting the metal contained in the raw material boron carbide powder with chlorine gas were set at 375° C., the same procedure as in Example 1 was carried out to produce three boron chloride. As a result, the iron content in the boron carbide from which the metal chloride was removed was 0.16% by mass. In addition, in the production reaction of boron trichloride, colored fouling thought to be metal chloride was not seen on the production pipeline of the boron trichloride production equipment, and the production pipeline of the boron trichloride production equipment did not occur clogged. Furthermore, the iron content in the produced boron trichloride was 80 mass ppb, and the aluminum content was 6 mass ppb. In addition, the yield of boron trichloride was 98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com