Fiber resin matrix composite pressure-resistant shell opening reinforcing and sealing structure

A composite material, pressure-resistant shell technology, applied in the direction of sealing shell, electrical equipment shell/cabinet/drawer, ships, etc., can solve the problems of difficult sealing, inability to disassemble, reducing strength, etc., to achieve good reliability and wide application range , The effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

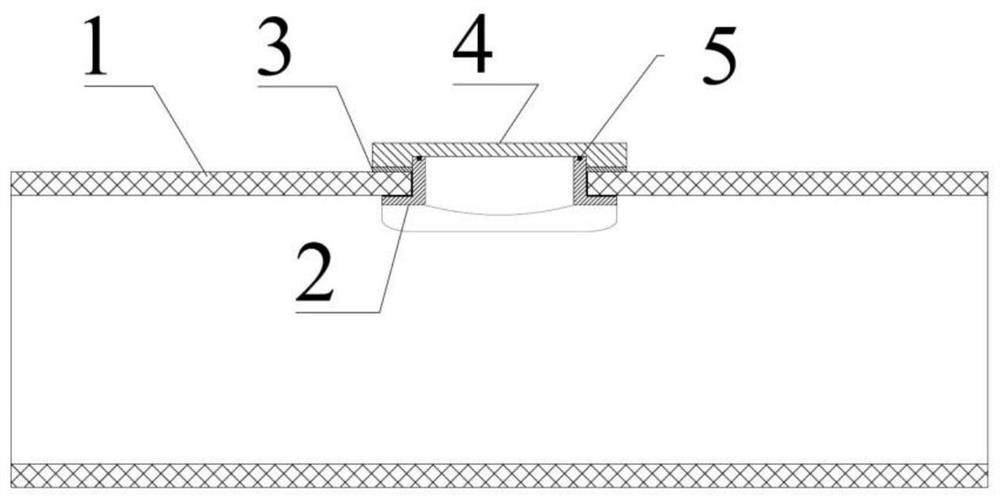

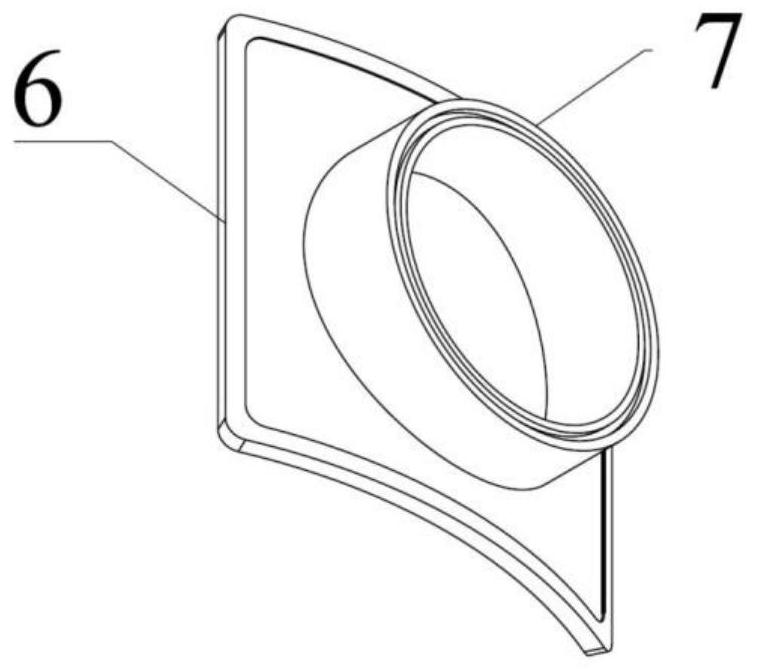

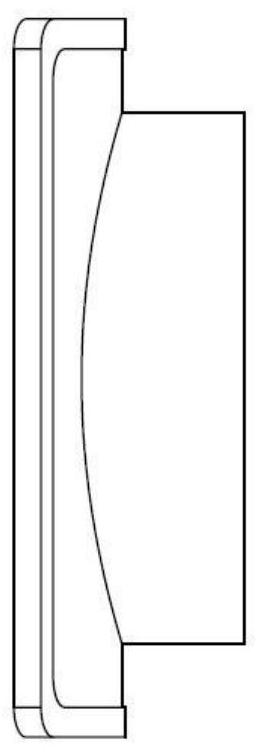

[0026] This embodiment is a fiber resin-based composite material pressure-resistant shell opening reinforcement sealing structure.

[0027] refer to Figure 1 to Figure 5(b) In this embodiment, the fiber resin-based composite material pressure-resistant housing has a hole-reinforced sealing structure, which consists of a composite material pressure-resistant housing 1, a reinforcement member 2, a non-standard sealing retaining ring 3, an end cover 4, a sealing ring 5, a bottom plate 6, and a surrounding The wall 7 is composed of epoxy resin glue; wherein, the pressure-resistant shell of carbon fiber resin matrix composite material is formed by a fiber winding process. The reinforcement is the main metal part that reinforces the opening of the fiber composite pressure-resistant shell. It is integrally formed, preferably made of high-strength titanium alloy material TC4, and manufactured by die-casting technology, or manufactured by machining or 3D additive manufacturing.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com