A kind of water-based graphene conductive paste and its preparation method and RFID tag

A technology of RFID tags and water-based graphene, applied in the field of graphene, can solve the problems of easy cracks, poor adhesion, affecting sensitivity and yield, etc., to achieve improved bonding effect and wear-resistant effect, environmental protection and human health. Harmful, good printing adaptability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

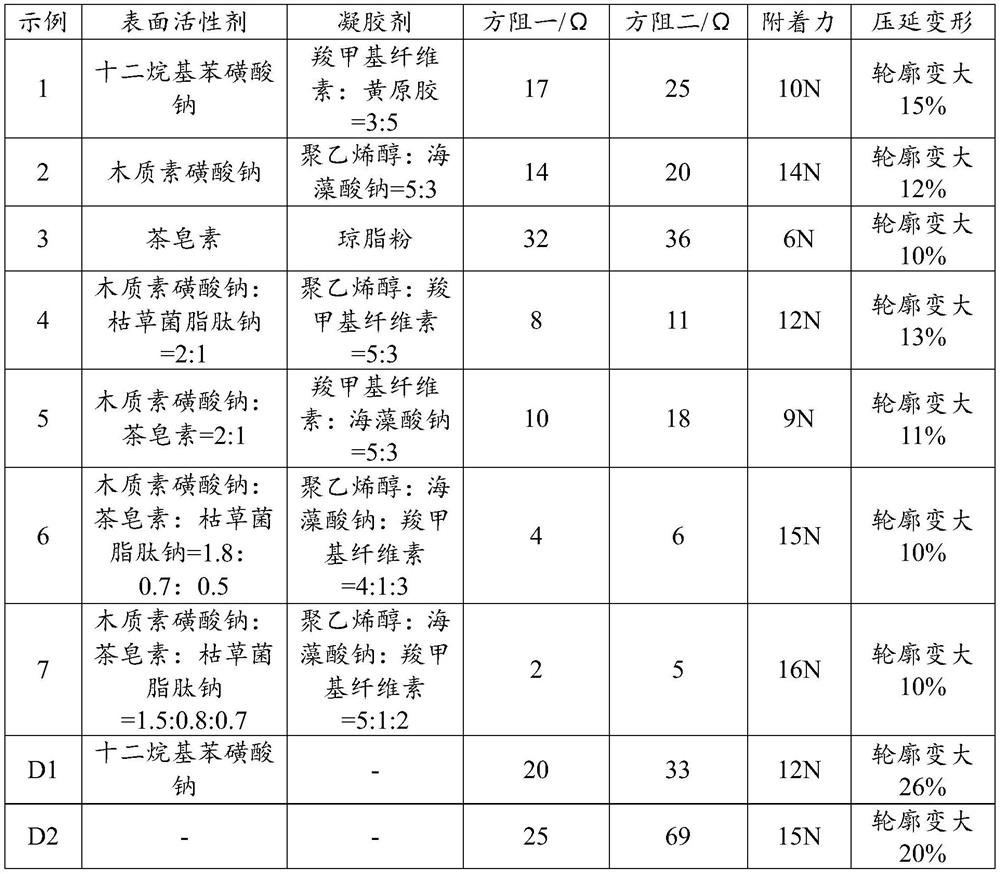

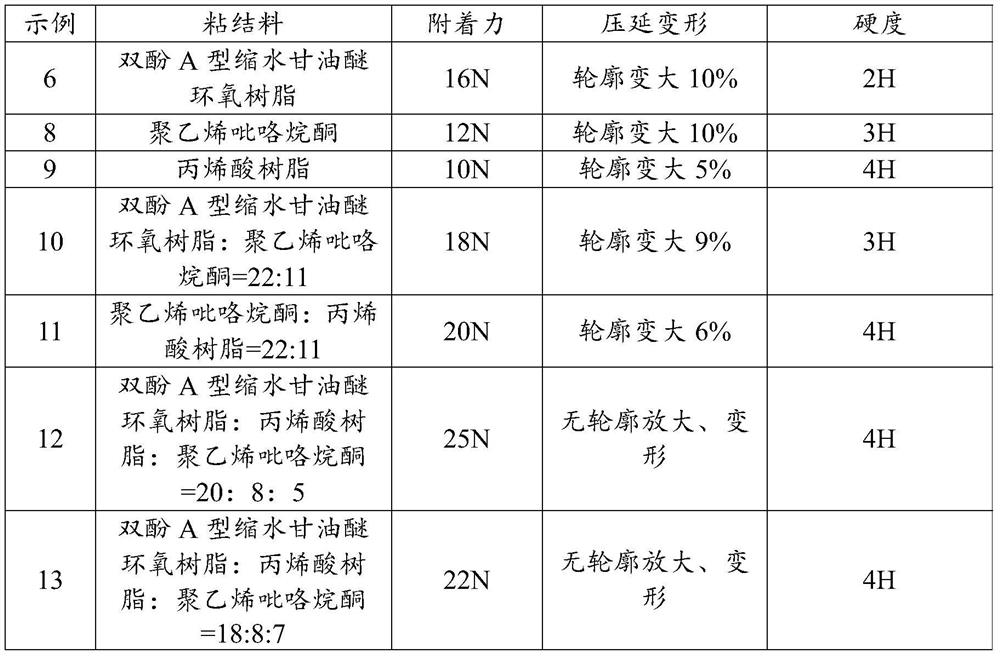

Examples

Embodiment 1

[0031] The present embodiment provides a water-based graphene conductive paste, which is composed of the following components in parts by weight:

[0032] 12 parts of graphene nanosheet powder (average particle size 30 microns, sheet thickness 1-15 nanometers), 40 parts of deionized water, 3 parts of surfactant, 8 parts of gelling agent, 33 parts of bisphenol A glycidyl ether ring Oxygen resin, 0.3 parts of 1-hydroxycycloethyl phenyl ketone, 1.7 parts of hydroxyethyl acrylate, 1 part of MONENG-1153, and 1 part of polydimethylsiloxane.

[0033] The above-mentioned raw material components are prepared by the following method to obtain the water-based graphene conductive paste:

[0034] Step 1. Under the condition of turning on ultrasonic dispersion and magnetic stirring at the same time, add the surfactant to deionized water and mix evenly. The ultrasonic frequency is 20kHz, and the magnetic stirring rate is 1800r / min. After mixing, add in 8-10 times Graphene is ultrasonically ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com