Display driving module, control method thereof and display driving system

A technology for driving modules and displays, applied to static indicators, instruments, etc., which can solve the problems of gray scale and refresh rate limitation, high noise, and easy to exceed the specification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The technical means adopted by the present invention to achieve the intended invention purpose are further described below in conjunction with the drawings and preferred embodiments of the present invention.

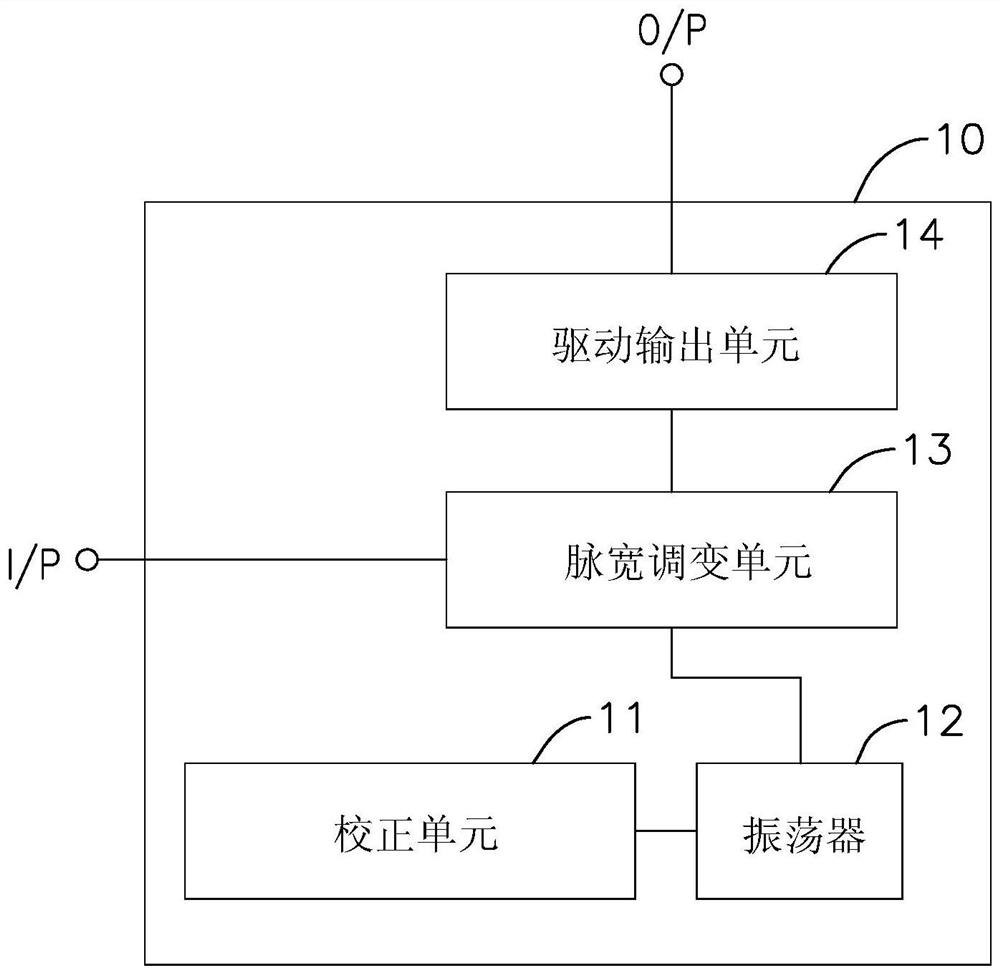

[0052] see figure 1 As shown, the present invention provides a display driving module 10, which has a driving information input terminal I / P and a driving signal output terminal O / P, and includes a calibration unit 11, an oscillator 12, a pulse width modulation Unit 13 and a drive output unit 14, the correction unit 11 stores a frequency correction information, the oscillator 12 is electrically connected to the correction unit 11 to receive the frequency correction information and generate a gray scale clock signal accordingly, the gray scale clock signal The frequency is within a target frequency range; the pulse width modulation unit 13 is electrically connected to the driving information input end to receive a driving information, and is electrically connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com