Silicon-based MEMS optical switch based on electrostatic comb driving, and N * N array

An optical switch array, optical switch technology, applied in the direction of light guide, optics, optical components, etc., can solve the problem of long switching time and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

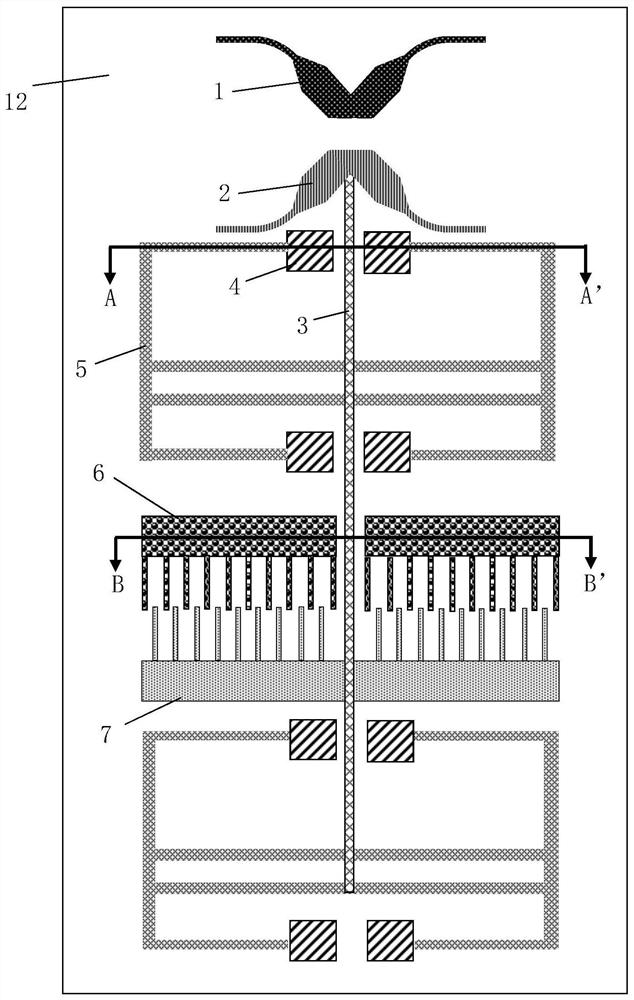

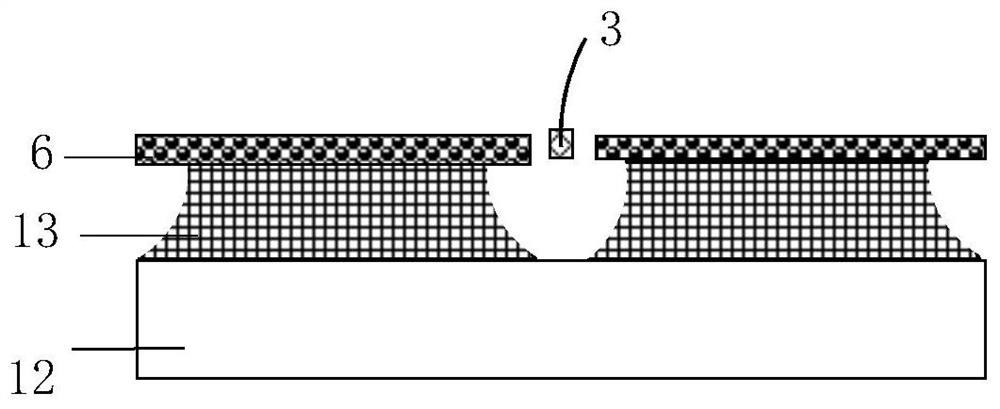

[0050] Such as figure 1 and Figure 4 As shown, the electrostatic comb driver of this embodiment is mainly composed of a pair of electrostatic comb teeth 6, 7, a first island spring structure, a second island spring structure and a transmission rod 3; The direction of movement is arranged. One end of the transmission rod 3 is fixedly connected to the movable cross waveguide mirror 2, specifically connected to the V-shaped intersection of the wide waveguide of the movable cross waveguide mirror 2. The transmission rod 3 is perpendicular to the total reflection surface of the movable cross waveguide mirror 2. A first island spring structure, a pair of electrostatic comb teeth 6, 7 and a second island spring structure are sequentially provided from the movable cross waveguide mirror 2 to the other end of the transmission rod 3 .

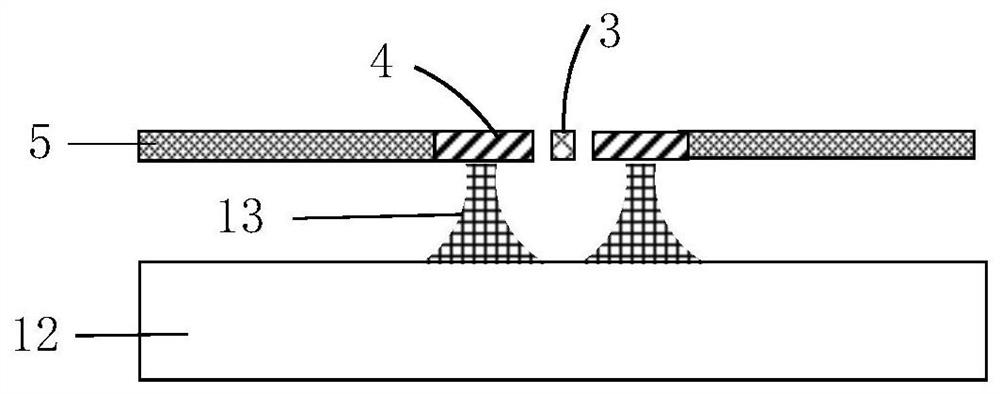

[0051] The structure of the first island spring structure and the second island spring structure are the same, both including four fixed islands 4 and...

Embodiment 2

[0062] Such as Figure 5 and Figure 6 As shown, the electrostatic comb driver of this embodiment is a bistable electrostatic comb driver, which is mainly composed of an electrostatic comb group, a third island spring structure, a fourth island spring structure and a transmission rod 3; the transmission rod 3 moves along the cross The moving direction of the waveguide mirror 2 is arranged. One end of the transmission rod 3 is fixedly connected to the movable cross waveguide mirror 2, specifically connected to the V-shaped intersection of the wide waveguide of the movable cross waveguide mirror 2. The transmission rod 3 and the movable cross waveguide mirror 2 The total reflection surface is vertical, and the third island spring structure, the electrostatic comb group and the fourth island spring structure are arranged sequentially from the movable cross waveguide mirror 2 to the other end of the transmission rod 3; the third island spring structure and the fourth island spring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Extinction ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com