Method for automatic coloring penetration detection in power station pipeline pre-detection stage

A coloring penetration and pipeline technology, which is applied in the direction of measuring devices, optical testing of defects/defects, and material analysis through optical means, can solve the problems of long occupational health inspection cycles and large manpower consumption of inspectors, and shorten the inspection cycle. The effect of reducing labor costs and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

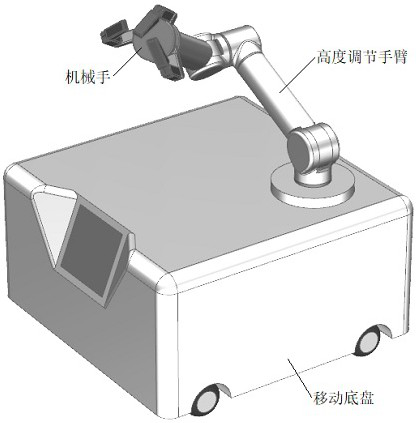

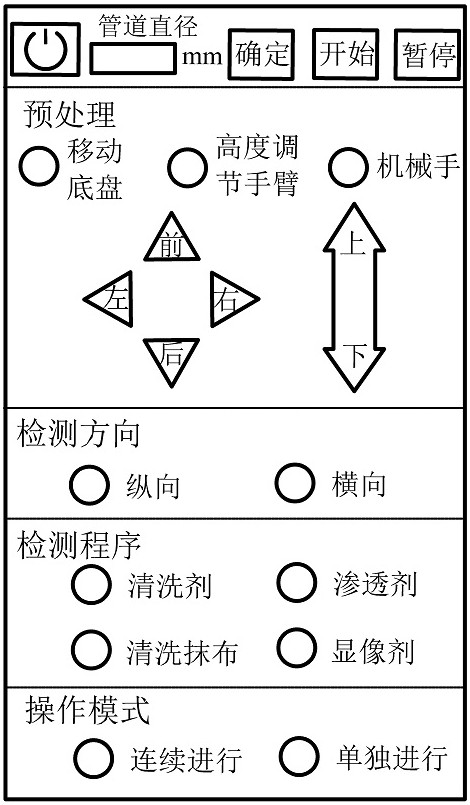

[0027] Click the power button on the interface of the terminal equipment, select "Mobile Chassis" in the preprocessing mode after starting up, and press the front, back, left and right keys according to the actual situation to make the device quickly move to the vicinity of the tested tube sample, also in the preprocessing mode Select "height adjustment arm", according to the actual situation, press the front, back, left, right, up and down keys to make the manipulator quickly move to the surface of the tube sample, and finally press the front, back, left, right, up and down keys according to the actual situation. The manipulator is precisely positioned to the detection starting point, which is generally set at the neutral plane of the pipeline where the detection starts, and the detection preprocessing is completed.

[0028] Enter the diameter of the pipeline to be detected, enter 540 on the device terminal interface, and click the "OK" button. In the detection direction mode...

Embodiment 2

[0032] The detection preprocessing work is the same as that in Embodiment 1, input the diameter of the pipeline to be detected, input 540 on the device terminal interface, and click the "OK" button. Select "Landscape" detection in the detection orientation mode. In the detection program mode, select the detection program to be used. In this embodiment, start from cleaning the tube sample, that is, select "cleaning agent". Select "Continuous" in the operation mode, so far, all the setting work has been completed, click the "Start" button to start the detection. The manipulator will start from the starting point and perform pre-cleaning in sequence along the medium flow direction, wait for the tube sample to dry (according to the ambient temperature range, the system is set to 3 minutes), apply penetrant, clean, and wait for the tube sample to dry (according to the ambient temperature range, the system Set it to 3 minutes), apply the imaging agent, and do not need human manipul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com