Novel gas heating water heater

A technology for gas heating and water heaters, applied to water heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as flame overflow, insufficient secondary pressure of gas, and flue blockage, so as to prevent smoke port from being blocked , accurate flow characteristics and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

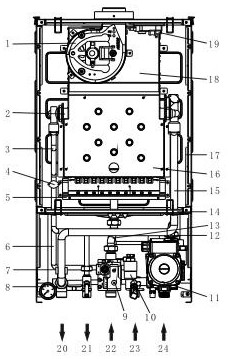

[0014] as attached figure 1 As shown, a new gas-fired heating water heater includes a fan, a main heat exchanger, a hot water outlet pipe assembly, a domestic hot water temperature probe, a burner unit, an inlet pipe assembly, an electric three-way valve, a pressure gauge, a gas Proportional valve, water inlet valve assembly, circulating water pump, water pump connection assembly, gas connection assembly, bottom plate, heating outlet pipe assembly, combustion chamber front cover, expansion tank, smoke hood installation, air pressure switch, heating outlet, living heat Water outlet, gas inlet, tap water inlet, heating return inlet, a wind pressure switch is installed on the upper right corner of the fan, a smoke hood is installed on the outside of the fan, the bottom of the fan is connected to the combustion chamber, and the outside of the combustion chamber The front cover of the combustion chamber is installed, the left side of the combustion chamber is connected to the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com