Hot-melt sizing machine based on hot-melt sizing agent

A sizing machine and hot-melt technology, which is applied in the processing of textile materials, processing textile material drums, processing textile material carriers, etc., can solve problems such as yarn damage, difficulty in sizing quality, and large yarn consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

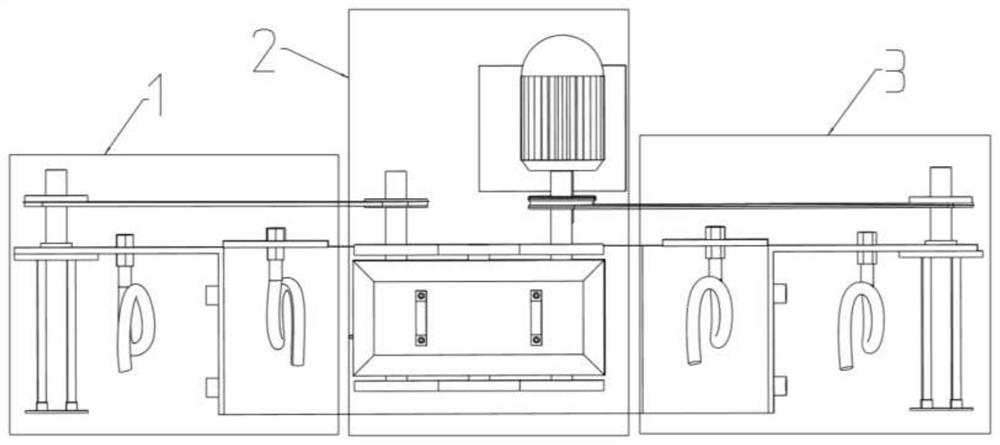

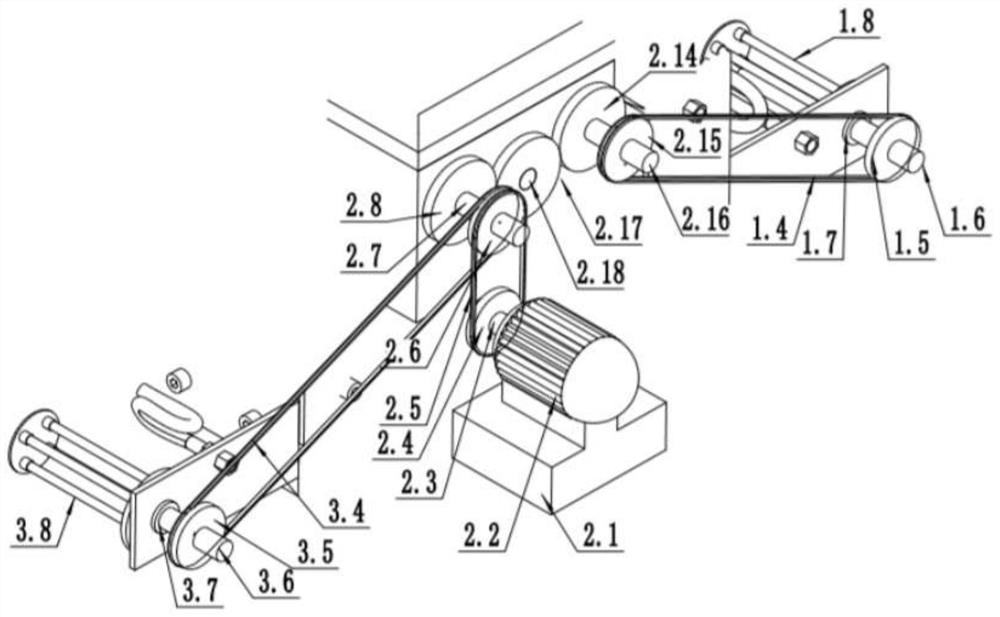

[0026] refer to figure 1 , the structure of the hot-melt sizing machine of the present invention is that, according to the yarn traveling route, a yarn feeding unit 1, a sizing unit 2, and a yarn winding unit 3 are sequentially arranged, and these three units are all driven and connected with the same transmission motor 2.2, called It is a single-input-multiple-output driving mode, and the transmission motor 2.2 and each main shaft of the corresponding unit are driven through their respective synchronous belts and gears, see figure 2 .

[0027] The device of the invention is controlled by a set of modularized temperature control mechanism, and monitors the slurry in the slurry tank in real time to ensure that the slurry is always in a molten state and the sizing quality is ensured.

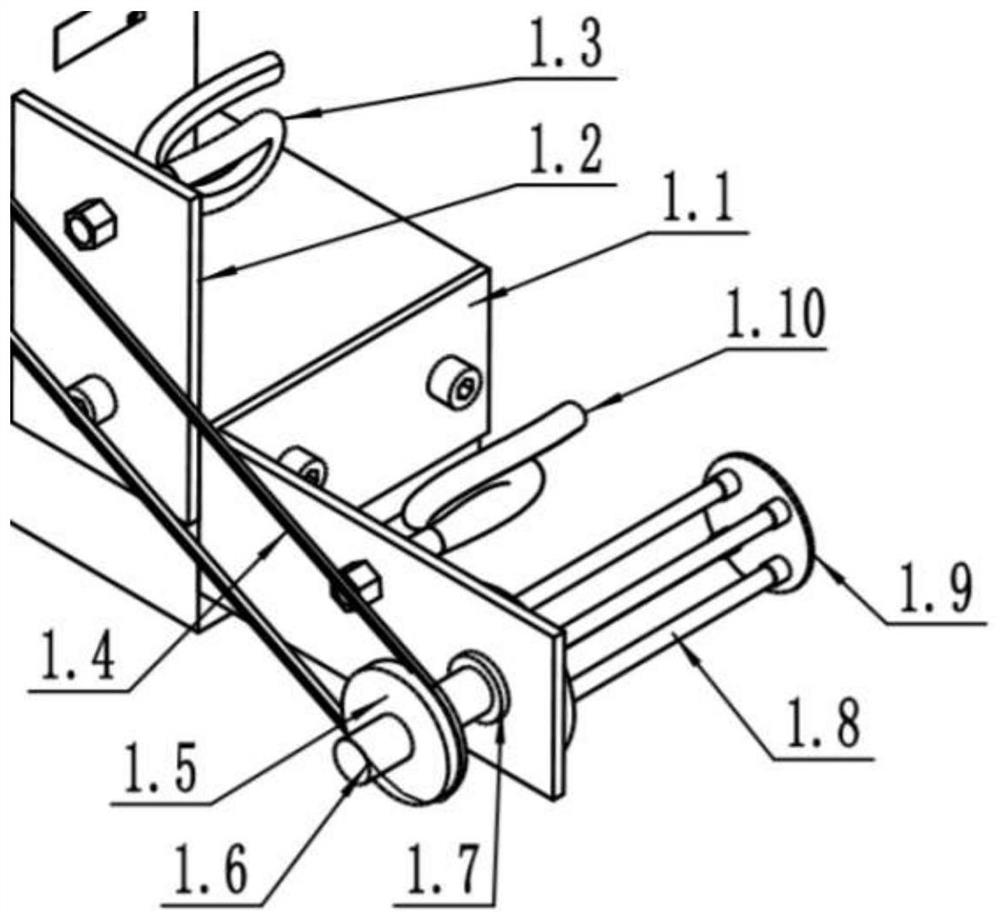

[0028] refer to figure 2 , Figure 4 , the transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com