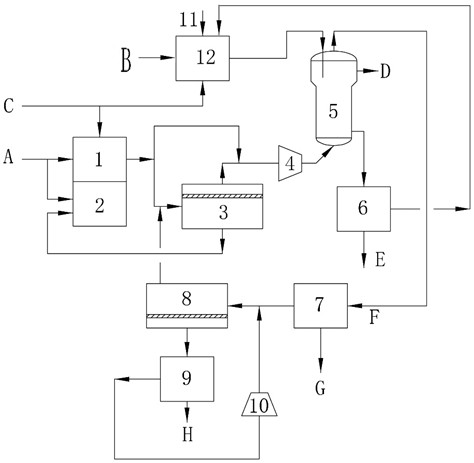

Natural gas hydrogen production and biomass liquefaction combined treatment system and process

A treatment system and treatment process technology, applied in the field of biomass catalytic liquefaction and natural gas reforming hydrogen production combined treatment system and treatment process, can solve the problems of high economic cost, unfavorable large-scale industrial application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

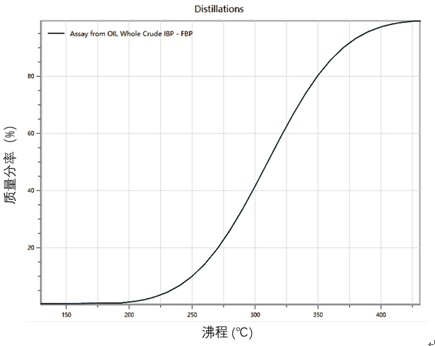

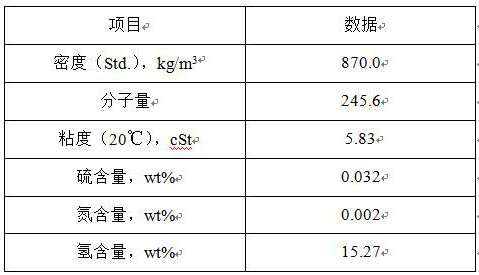

[0071] In this example, lignocellulose is used as the raw material (the raw material is in the state of granular powder, with a particle size of 0.1-0.3 mm), and cyclohexane and diesel oil are used as solvents, wherein the mass ratio of the solvent to the biomass raw material is 0.3, and the cyclohexane in the solvent is The mass ratio of alkane to diesel oil is 0.1; in the biomass raw material pretreatment unit 12, it is fully mixed and fed with steam, and the molar flow ratio of the steam molar flow to the synthesis gas entering the biomass liquefaction reactor is 2:1; where The operating temperature of the natural gas reforming hydrogen production unit is 622~1335°C, the operating pressure is 2.7MPag, and the space velocity is 20000h -1 ; 20% of the synthesis gas from the natural gas steam reforming reaction product enters the synthesis gas ratio adjustment membrane separator; the membrane area of the synthesis gas ratio adjustment membrane separator is 260m 2 , the cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com